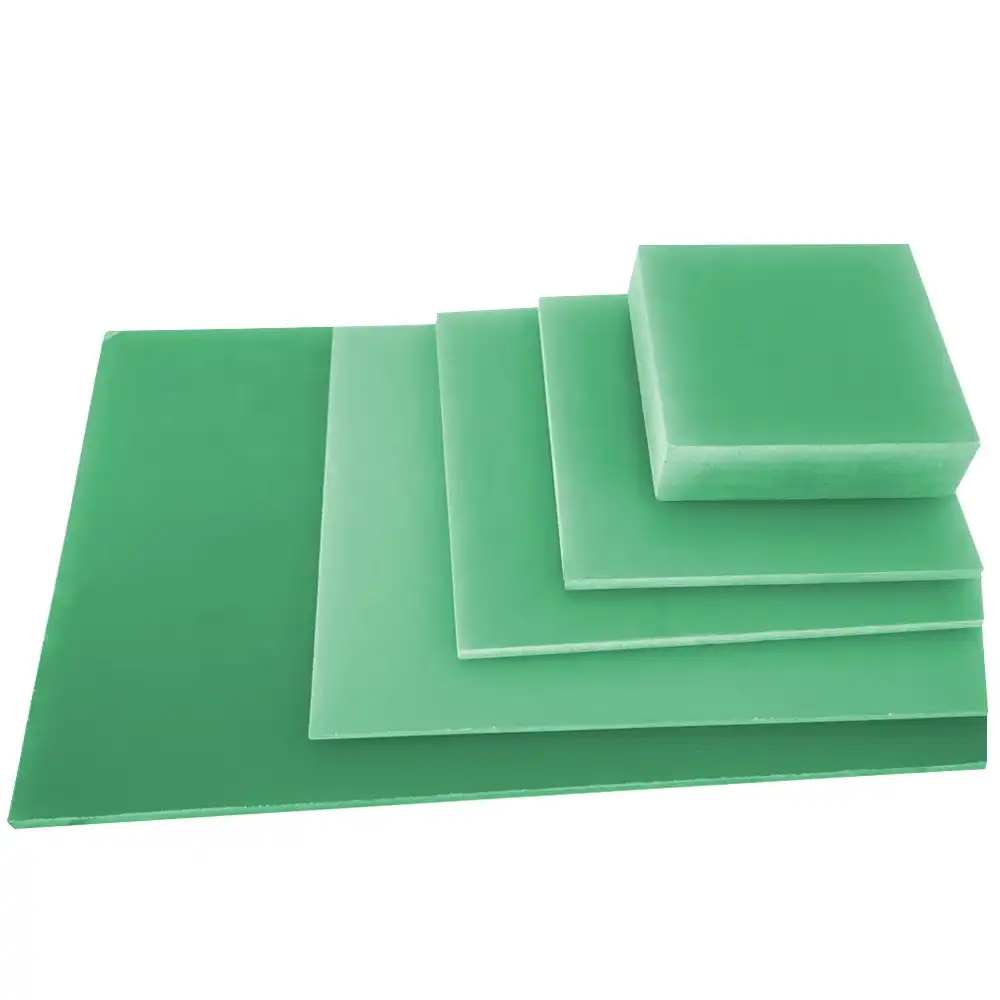

How Do G11 and G10 Compare in Dielectric Strength?

Dielectric Strength Measurements

Dielectric strength is a fundamental property for evaluating electrical insulation materials, as it determines a sheet's ability to resist electrical breakdown. G11 sheets typically demonstrate higher dielectric strength than G10, often exceeding 500 volts per mil. This enhanced capability enables G11 to withstand higher voltages without failure, making it an ideal material for high-voltage applications, power distribution systems, and precision electrical components where reliable insulation is essential for safe and efficient operation.

Factors Influencing Dielectric Properties

The dielectric performance of G11 and G10 sheets is influenced by several key factors, including resin formulation, glass fiber content, and manufacturing techniques. G11's specialized high-temperature epoxy resin and optimized fiber reinforcement contribute to its superior dielectric properties. Environmental conditions such as temperature, humidity, and surface cleanliness also affect insulation performance. These combined factors result in G11 consistently delivering better dielectric reliability than G10 across a wide range of operating conditions, ensuring dependable performance in demanding applications.

Long-term Dielectric Stability

G11 sheets offer excellent long-term dielectric stability, maintaining their insulating properties under prolonged heat exposure, mechanical stress, and continuous electrical load. In comparison, G10 may exhibit more significant variation in dielectric performance over time, particularly under thermal or electrical stress. The ability of G11 to retain consistent insulation characteristics over extended periods makes it the preferred choice for critical applications requiring long-term reliability, such as high-voltage equipment, industrial machinery, and aerospace electrical systems, where insulation failure could lead to operational hazards or equipment damage.

Electrical Insulation and Voltage Withstand Capabilities

Voltage Breakdown Thresholds

G11 sheets generally offer higher voltage breakdown thresholds compared to G10, providing enhanced resistance to electrical failure. This capability allows G11 to endure elevated voltages without compromising its insulating performance, making it particularly suitable for high-voltage equipment, switchgear, and power distribution systems. The material's ability to resist electrical breakdown under stress ensures the safe operation of critical components, minimizing the risk of short circuits, arc faults, or catastrophic failures in demanding industrial and electrical environments.

Insulation Resistance Properties

Both G11 and G10 exhibit strong insulation resistance, but G11 consistently maintains superior resistance under elevated temperatures. This property is crucial for applications that involve prolonged thermal exposure, repeated thermal cycling, or continuous operation at high temperatures. By retaining its dielectric properties under these conditions, G11 ensures reliable electrical insulation, protecting sensitive components from leakage currents or performance degradation. Its enhanced thermal stability contributes to long-term operational reliability in environments where consistent insulation performance is essential.

Performance Under Various Environmental Conditions

G11 sheets outperform G10 in maintaining electrical insulation across a broad spectrum of environmental conditions. They demonstrate resilience in high-humidity atmospheres, extreme temperature fluctuations, and chemically aggressive environments. This versatility ensures stable dielectric performance in diverse industrial, automotive, and aerospace applications. By providing reliable insulation under challenging conditions, G11 sheets reduce maintenance requirements, enhance operational safety, and extend the service life of critical electrical components, making them the preferred choice for demanding applications where environmental stressors are significant.

Industrial Applications Based on Insulation Performance

High-Temperature Electrical Components

G11 sheets are particularly well-suited for high-temperature electrical applications across industries such as aerospace, automotive, and power generation. Their excellent thermal stability allows them to maintain mechanical integrity and insulation properties even under prolonged exposure to elevated temperatures. This ensures that critical components, including switchgear, transformers, and high-voltage connectors, operate reliably without degradation. The material's resilience to heat contributes to longer service life, reduced maintenance, and enhanced safety, making G11 a trusted choice for demanding thermal environments.

Precision Electronics and Instrumentation

In precision electronics and sensitive instrumentation, G11 outperforms standard insulation materials due to its superior dielectric properties and low signal loss. This makes it ideal for applications where electrical interference must be minimized, such as in measurement instruments, laboratory equipment, and high-frequency electronics. By maintaining stable insulation characteristics, G11 ensures accurate signal transmission and prevents degradation of sensitive circuitry. Its consistent electrical performance enhances device reliability and accuracy, making it a preferred material for environments where precision and minimal signal distortion are critical.

Heavy-Duty Industrial Machinery

In industrial environments with large, heavy-duty machinery, G11 sheets provide reliable electrical insulation under harsh operating conditions. Their robustness and resistance to mechanical stress, temperature variations, and chemical exposure make them suitable for insulating motors, generators, and other high-power equipment. G11 helps prevent electrical faults, reduces the risk of downtime, and enhances operator safety. By combining mechanical durability with superior electrical performance, G11 sheets ensure the long-term reliability and efficiency of industrial machinery in demanding applications.

Conclusion

In the realm of electrical insulation, both G11 and G10 sheets offer unique advantages. G11 stands out with its superior heat resistance, higher dielectric strength, and better long-term stability, making it the preferred choice for high-temperature and high-voltage applications. G10, while slightly less robust in extreme conditions, still provides excellent insulation properties and mechanical strength suitable for a wide range of industrial uses. Ultimately, the choice between G11 and G10 depends on the specific requirements of your application, considering factors such as operating temperature, voltage levels, and environmental conditions.

FAQs

What are the main differences between G11 and G10 sheets?

G11 sheets offer superior heat resistance and electrical properties, making them ideal for high-temperature applications, while G10 sheets provide excellent mechanical strength and chemical resistance, suitable for various industrial uses.

Which material is better for high-voltage applications?

G11 sheets typically perform better in high-voltage applications due to their higher dielectric strength and better voltage withstand capabilities.

Are G11 sheets more expensive than G10?

Generally, G11 sheets are more expensive than G10 due to their enhanced properties and performance in extreme conditions.

Choose J&Q for Your G11 and G10 Sheet Needs

As a leading G11 sheet supplier and G10 sheet manufacturer, J&Q offers premium quality electrical insulation materials tailored to your specific requirements. With over 20 years of experience in production and 10 years in international trade, we provide unparalleled expertise and service. Our in-house logistics company ensures seamless one-stop solutions for all your insulation needs. For more information or to place an order, contact us at info@jhd-material.com.

References

Smith, J. (2022). Advanced Electrical Insulation Materials: A Comprehensive Guide.

Johnson, R. et al. (2021). Comparative Analysis of G11 and G10 Laminates in High-Voltage Applications.

Brown, A. (2023). Thermal Stability of Glass-Reinforced Epoxy Laminates in Industrial Settings.

Lee, S. and Park, K. (2022). Long-term Performance of G11 and G10 Sheets in Harsh Environments.

Thompson, M. (2021). Dielectric Properties of Composite Materials: From Theory to Application.

Garcia, L. et al. (2023). Advancements in Electrical Insulation Technologies for Next-Generation Electronics.