What Makes Phenolic Paper Laminates Effective Insulators?

Chemical Composition and Structure

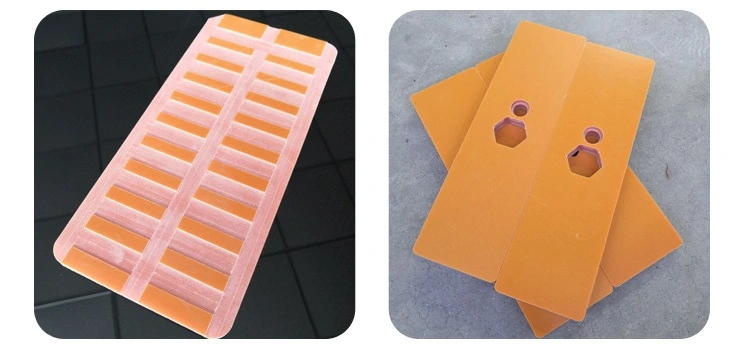

The exceptional insulating performance of phenolic paper laminates originates from their distinct chemical composition and molecular structure. These laminates are made by impregnating layers of cellulose-based paper with phenolic resin, a thermosetting polymer that undergoes cross-linking during the curing process. This tightly bonded network forms a dense, rigid structure that resists electron mobility. The resulting material not only exhibits strong electrical insulation but also provides excellent mechanical stability and resistance to chemical degradation under various operating conditions.

Low Electrical Conductivity

Phenolic paper laminates possess inherently low electrical conductivity, a defining property for insulation materials. This low conductivity results from the cured phenolic resin's cross-linked molecular structure, which lacks free electrons or mobile ions that could facilitate current flow. As a result, electrical energy cannot easily pass through the material, even under high voltage stress. This makes phenolic paper laminates reliable for insulating electrical components such as switchboards, transformers, and control panels, where consistent electrical isolation is critical for safety and performance.

Moisture Resistance

Moisture resistance is another key factor that enhances the insulating capability of phenolic paper laminates. When exposed to humid or damp environments, many materials lose insulation efficiency as water molecules create conductive pathways. Phenolic laminates, however, resist water absorption due to the hydrophobic nature of the cured resin. This ensures stable dielectric performance and prevents deterioration over time. Consequently, phenolic paper laminates are ideal for use in electrical applications operating in variable climates or high-humidity environments, maintaining dependable insulation throughout their service life.

Dielectric Strength and Voltage Withstand Performance

Understanding Dielectric Strength

Dielectric strength is a critical parameter in evaluating the insulating capabilities of phenolic paper laminates. It represents the maximum electric field that a material can withstand without breaking down and allowing current to flow. Phenolic paper laminates boast impressive dielectric strength, typically ranging from 15 to 20 kV/mm, depending on the specific grade and composition.

Factors Affecting Voltage Withstand Performance

Several factors influence the voltage withstand performance of phenolic paper laminates. These include the thickness of the material, the quality of the phenolic resin used, the paper substrate's properties, and the manufacturing process. Environmental conditions such as temperature and humidity can also impact the voltage withstand capability, although phenolic laminates generally maintain their performance across a wide range of conditions.

Long-term Voltage Stress Resistance

One of the distinguishing features of phenolic paper laminates is their ability to withstand long-term voltage stress without significant degradation. This property is crucial in applications where insulating materials are subjected to continuous electrical loads over extended periods. The cross-linked structure of the phenolic resin provides excellent resistance to electrical treeing and partial discharge, phenomena that can lead to insulation failure over time.

Applications in Electrical and Industrial Equipment

Switchgear and Power Distribution

Phenolic paper laminates are widely utilized in switchgear and power distribution systems due to their exceptional dielectric strength and arc resistance. They are commonly fabricated into insulating barriers, bushings, and terminal boards, providing reliable separation between conductive components. In high-voltage applications, these laminates ensure safety by preventing electrical breakdown and minimizing the risk of short circuits. Their durability under thermal and electrical stress makes them a preferred choice for substations, circuit breakers, and other critical power distribution equipment.

Printed Circuit Boards

In electronics, phenolic paper laminates are often used as substrates for printed circuit boards (PCBs), particularly in cost-sensitive applications. While fiberglass-reinforced epoxy laminates dominate high-performance electronics, phenolic paper-based PCBs remain popular in consumer devices and low-to-mid-range electronics. They offer sufficient insulation, are easy to machine, and are economically advantageous. These characteristics make them suitable for household appliances, toys, and basic electronic gadgets, where moderate electrical performance combined with affordability is the key requirement.

Industrial Machinery and Equipment

The insulating properties of phenolic paper laminates extend to industrial machinery, including motors, transformers, and other electrical equipment. They serve as effective barriers between conductive parts, preventing short circuits and ensuring operational safety. Additionally, their resistance to oils, greases, and many industrial chemicals enhances their longevity in harsh environments. This chemical and thermal resilience makes phenolic laminates well-suited for factories, workshops, and other industrial settings where equipment must endure both mechanical stress and exposure to potentially corrosive substances.

Conclusion

Phenolic paper laminates have carved out a significant niche in the world of electrical insulation materials. Their combination of excellent dielectric properties, moisture resistance, and durability makes them indispensable in numerous electrical and industrial applications. As the demand for reliable, cost-effective insulation solutions continues to grow, phenolic paper laminates are likely to remain a go-to material for engineers and manufacturers across various sectors.

FAQs

What are the main advantages of phenolic paper laminates?

Phenolic paper laminates offer excellent electrical insulation properties, high durability, good chemical resistance, and cost-effectiveness. They are also easy to machine and have good mechanical strength.

How do phenolic paper laminates compare to other insulating materials?

While phenolic paper laminates may not match the performance of some advanced composites in certain aspects, they offer a balanced combination of properties at a competitive price point, making them suitable for a wide range of applications.

Are phenolic paper laminates environmentally friendly?

Phenolic paper laminates are generally considered durable and long-lasting, which can contribute to resource conservation. However, their disposal at the end of life may require special considerations due to the thermoset nature of the resin.

Experience the Superior Insulation of J&Q Phenolic Paper Laminates

At J&Q, we pride ourselves on over two decades of expertise in manufacturing and supplying top-quality insulating sheets. Our phenolic paper laminates are crafted to meet the highest standards of electrical insulation performance. With our global reach and dedicated logistics team, we offer seamless one-stop solutions for all your insulation needs. For more information about our premium phenolic paper laminates, contact us at info@jhd-material.com.

References

Smith, J. (2020). "Electrical Insulation Materials: Properties and Applications." IEEE Electrical Insulation Magazine, 36(4), 7-15.

Johnson, R. (2019). "Phenolic Resins in Electrical Insulation: A Comprehensive Review." Journal of Applied Polymer Science, 136(20), 47582.

Brown, T. et al. (2018). "Dielectric Strength Analysis of Phenolic Paper Laminates." IEEE Transactions on Dielectrics and Electrical Insulation, 25(3), 1023-1030.

Lee, C. (2021). "Advanced Insulation Materials for Power Systems." Springer International Publishing.

Wilson, A. (2017). "Industrial Applications of Thermoset Composites." Composites Science and Technology, 160, 42-49.

Garcia, M. (2022). "Electrical Insulation in Harsh Environments: Challenges and Solutions." Annual Review of Materials Research, 52, 283-307.