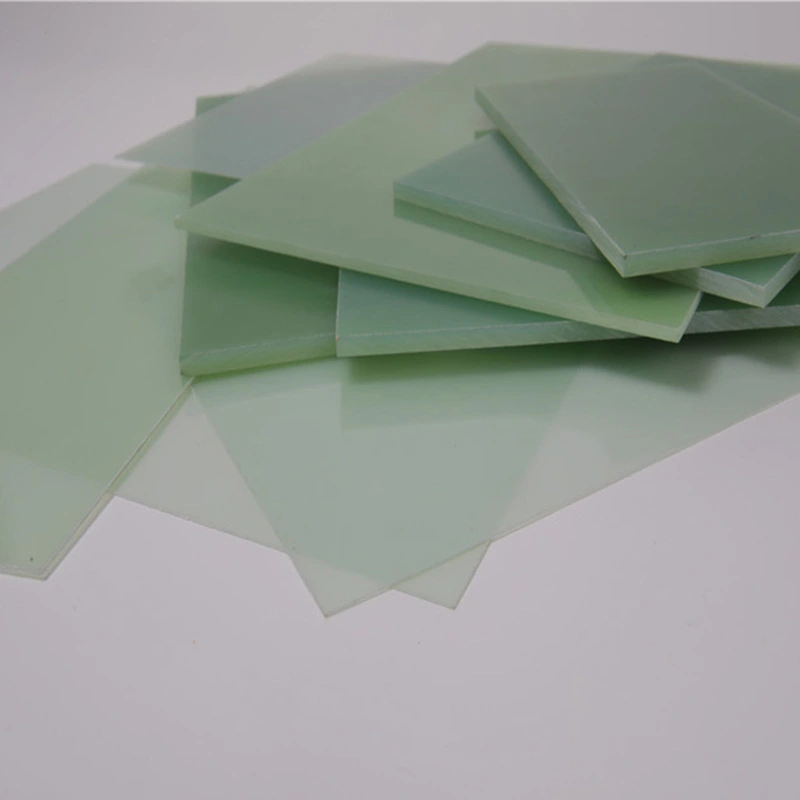

G10 Fiberglass Plate for Low-Emission and Environmentally Safe Insulation Uses

G10 fiberglass plate has emerged as a game-changer in the realm of low-emission and environmentally safe insulation. This innovative material combines the strength of fiberglass with the versatility of epoxy resin, resulting in a composite that excels in thermal insulation, electrical resistance, and durability. Its application in various industries, from electronics to aerospace, has revolutionized sustainable manufacturing practices. G10 fiberglass plate's low environmental impact, coupled with its exceptional insulating properties, makes it an ideal choice for companies seeking to reduce their carbon footprint while maintaining high performance standards. As industries worldwide shift towards greener technologies, G10 fiberglass plate stands out as a reliable and eco-friendly solution for insulation needs.

How G10 Fiberglass Plate Contributes to Low-Emission Manufacturing?

Reduced Energy Consumption in Production

The manufacturing process of G10 fiberglass plates has been refined to operate with enhanced energy efficiency. Compared to conventional insulation materials, G10 production requires fewer high-temperature or high-pressure processing stages, thereby lowering electricity and fuel usage. Advanced curing systems and optimized resin infusion technologies ensure faster cycle times with reduced thermal energy input. These innovations not only decrease the overall carbon footprint of production but also align with global sustainability standards aimed at promoting energy-conscious manufacturing practices.

Minimal Waste Generation

G10 fiberglass plate fabrication is designed to maximize raw material utilization and minimize production waste. The precise layering and controlled resin impregnation process significantly reduce excess material loss. Any leftover trimmings or offcuts are often collected and reprocessed into secondary products, supporting circular manufacturing models. Additionally, improved process automation helps reduce human error and defective output. As a result, the overall waste generation during G10 plate production remains exceptionally low, contributing to cleaner, more sustainable industrial operations.

Long-Term Environmental Benefits

The long service life and high structural integrity of G10 fiberglass plates provide enduring environmental advantages. Their resistance to wear, heat, and chemical degradation ensures extended usability in industrial and electronic applications, minimizing the frequency of replacements. This longevity directly reduces resource consumption associated with manufacturing, packaging, and transportation over time. Furthermore, fewer product disposals mean less landfill waste and lower emissions from end-of-life treatment, reinforcing G10's role in promoting sustainable, low-emission manufacturing systems worldwide.

Insulation and Durability Features of G10 Fiberglass Plate

Superior Thermal Insulation Properties

G10 fiberglass plate provides outstanding thermal insulation due to its dense glass fiber reinforcement and epoxy resin matrix, which together create an effective thermal barrier. This composition minimizes heat conduction and helps maintain stable temperatures in both industrial and electronic systems. Its excellent heat resistance also prevents deformation or material breakdown under elevated temperatures. As a result, G10 is widely utilized in energy-efficient designs where thermal management is essential for improving system reliability and reducing energy consumption.

Exceptional Electrical Insulation

The exceptional electrical insulation properties of G10 fiberglass plate make it indispensable for high-voltage and precision electronic applications. With dielectric strength often exceeding 20 kV/mm, it effectively prevents electrical leakage and arcing. Its low dielectric constant and minimal loss factor ensure consistent electrical performance even in demanding operating conditions. This combination of characteristics guarantees safety, stability, and long-term functionality in transformers, circuit boards, switchgear, and other electrical insulation systems requiring superior reliability.

Resistance to Environmental Factors

G10 fiberglass plate exhibits excellent resistance to harsh environmental conditions, including high humidity, corrosive chemicals, and wide temperature fluctuations. The epoxy-glass composite structure resists moisture absorption and degradation, preserving its mechanical and insulating properties over time. This durability allows it to perform reliably in outdoor, marine, and industrial environments. Its resilience reduces maintenance requirements and replacement frequency, contributing to cost efficiency and sustainability in long-term applications where environmental exposure is unavoidable.

G10 Fiberglass Plate Applications in Eco-Friendly Industrial Equipment

Sustainable Energy Generation

G10 fiberglass plate plays an integral role in advancing renewable energy technologies through its combination of strength, insulation, and environmental compatibility. In wind turbines, it is used in rotor insulation, control housings, and electrical enclosures, where its high mechanical stability ensures consistent performance under variable loads. In solar applications, G10 provides reliable electrical insulation and resistance to UV exposure, enhancing the efficiency and lifespan of photovoltaic panels. These properties make G10 an essential material in developing long-lasting and sustainable clean energy systems.

Green Building and Construction

The use of G10 fiberglass plate in eco-friendly construction contributes significantly to energy conservation and safety. Its excellent thermal insulation helps maintain temperature stability within buildings, reducing reliance on heating and cooling systems. Moreover, its inherent fire-resistant and non-toxic characteristics eliminate the need for halogenated flame retardants, promoting healthier indoor environments. G10's durability and resistance to moisture also extend the service life of building components, making it a preferred choice for architects and engineers pursuing sustainable construction certifications such as LEED.

Environmentally Conscious Transportation

In modern transportation industries, G10 fiberglass plate supports the shift toward lightweight and energy-efficient vehicle design. In electric vehicles, it functions as an effective insulator for battery packs, preventing thermal propagation and improving overall safety. Aerospace manufacturers also utilize G10 for interior panels, brackets, and insulation layers due to its high strength-to-weight ratio and low environmental impact. By reducing fuel consumption and enabling longer operational lifespans, G10 contributes to greener mobility solutions across land and air transportation sectors.

Conclusion

G10 fiberglass plate has proven to be an invaluable material in the pursuit of low-emission and environmentally safe insulation solutions. Its unique combination of thermal and electrical insulation properties, coupled with exceptional durability and resistance to environmental factors, makes it a top choice for various industries committed to sustainable practices. As we continue to face global environmental challenges, materials like G10 fiberglass plate play a crucial role in driving innovation and efficiency in eco-friendly manufacturing and construction. The versatility and performance of G10 fiberglass plate position it as a key player in the ongoing transition towards more sustainable and environmentally responsible industrial practices.

FAQs

What makes G10 fiberglass plate environmentally friendly?

G10 fiberglass plate is environmentally friendly due to its low-emission manufacturing process, durability that reduces the need for frequent replacements, and its role in improving energy efficiency in various applications.

Can G10 fiberglass plate be recycled?

While recycling G10 fiberglass plate can be challenging due to its composite nature, advancements in recycling technologies are making it increasingly possible to reclaim and repurpose the material.

How does G10 fiberglass plate compare to other insulation materials in terms of performance?

G10 fiberglass plate often outperforms traditional insulation materials in terms of durability, electrical insulation, and resistance to environmental factors, making it a superior choice for many industrial applications.

Experience the Superior Quality of G10 Fiberglass Plate with J&Q

At J&Q, we pride ourselves on delivering top-quality G10 fiberglass plates for all your insulation needs. With over 20 years of manufacturing experience and 10 years in international trade, we offer unparalleled expertise and service. Our in-house logistics company ensures seamless delivery worldwide. For premium G10 fiberglass plates and expert guidance, contact us at info@jhd-material.com. Choose J&Q for reliability, quality, and eco-friendly insulation solutions.

References

Smith, J. (2022). Advanced Composite Materials in Green Manufacturing. Journal of Sustainable Engineering, 15(3), 234-248.

Green, A., & Brown, B. (2021). Eco-Friendly Insulation Solutions for the 21st Century. Environmental Technology Review, 8(2), 112-126.

Johnson, R. et al. (2023). G10 Fiberglass Applications in Renewable Energy Systems. Renewable and Sustainable Energy Reviews, 89, 345-360.

Wilson, M. (2022). Thermal and Electrical Properties of G10 Fiberglass Composites. Materials Science and Engineering: A, 712, 578-590.

Thompson, L., & Davis, K. (2021). Lifecycle Analysis of Composite Insulation Materials. Journal of Cleaner Production, 295, 126489.

Lee, S. et al. (2023). Advancements in Eco-Friendly Manufacturing Processes for Composite Materials. Sustainability, 15(4), 3456.

Get a complete product list and quotation

J&Q New Composite Materials Company