Understanding FR4 Materials: Composition and Properties

Chemical Composition of FR4

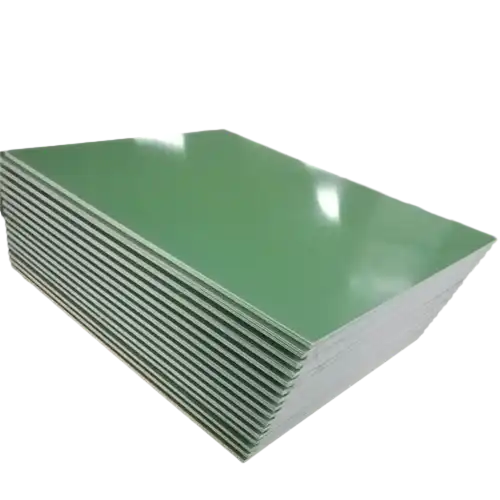

FR4 materials are composed of a carefully engineered blend of epoxy resin and woven fiberglass cloth. This combination results in a robust laminate that exhibits exceptional electrical and mechanical properties. The epoxy resin acts as a binder, encapsulating the fiberglass reinforcement and providing the material with its characteristic strength and durability. The fiberglass cloth, typically made from E-glass fibers, contributes to the material's high tensile strength and dimensional stability. This unique composition allows FR4 sheets to maintain their integrity under various environmental conditions, making them ideal for use in PCB manufacturing.

Key Properties of FR4 Epoxy Sheets

FR4 epoxy boards boast an impressive array of properties that make them suitable for diverse applications in the electronics industry. One of the most significant properties is their excellent electrical insulation, with a dielectric constant typically ranging from 4.0 to 4.5 at 1 MHz. This characteristic ensures minimal signal loss and crosstalk in high-frequency applications. Additionally, FR4 materials exhibit low moisture absorption, typically less than 0.5% by weight, which helps maintain the electrical and mechanical properties of the PCB even in humid environments. The thermal stability of FR4 is another crucial factor, with a glass transition temperature (Tg) usually between 130°C and 180°C, allowing for reliable operation in a wide range of temperatures.

FR4 Grade Classifications

FR4 materials are available in various grades, each tailored to specific application requirements. The most common classifications include standard FR4, high-Tg FR4, and halogen-free FR4. Standard FR4 is suitable for most general-purpose applications, while high-Tg FR4 offers improved thermal stability for more demanding environments. Halogen-free FR4 variants are designed to meet stringent environmental regulations and are increasingly popular in eco-friendly electronic products. These different grades allow manufacturers to select the most appropriate FR4 sheet for their specific PCB design, balancing performance requirements with cost considerations.

FR4 in PCB Manufacturing: Processes and Techniques

Lamination Process

The lamination process is a crucial step in PCB manufacturing using FR4 materials. It involves stacking multiple layers of FR4 epoxy sheets, interspersed with copper foil and prepreg layers, under high pressure and temperature. This process creates a solid, multi-layer board with excellent bonding between layers. The precise control of temperature and pressure during lamination is essential to ensure uniform curing of the epoxy resin and prevent issues such as delamination or warpage. Advanced lamination techniques, such as vacuum lamination, are often employed to enhance the quality and reliability of multi-layer PCBs made from FR4 epoxy boards.

Drilling and Plating Techniques

Drilling and plating are critical processes in PCB manufacturing that leverage the unique properties of FR4 materials. The drilling process creates holes for vias, component leads, and mounting hardware. FR4's composition allows for clean, precise drilling without excessive wear on tools. After drilling, the holes undergo a plating process to create electrically conductive paths between layers. The plating process typically involves electroless copper deposition followed by electrolytic copper plating. FR4's low moisture absorption and good adhesion properties ensure excellent plating results, contributing to the overall reliability of the PCB.

Surface Finishing Methods

Surface finishing is the final step in PCB manufacturing, providing protection and enhancing the solderability of the copper traces. FR4 epoxy sheets are compatible with various surface finish options, including Hot Air Solder Leveling (HASL), Electroless Nickel Immersion Gold (ENIG), Immersion Tin, and Organic Solderability Preservative (OSP). The choice of surface finish depends on factors such as the intended application, environmental conditions, and soldering requirements. FR4's thermal stability and chemical resistance make it suitable for most surface finishing processes, ensuring a high-quality, long-lasting PCB surface.

Advantages and Applications of FR4 in Modern Electronics

Thermal Management Benefits

FR4 materials offer significant advantages in thermal management for PCBs. The relatively low thermal conductivity of FR4 epoxy sheets helps insulate heat-sensitive components from other parts of the circuit. This property is particularly beneficial in designs where thermal isolation is crucial. Additionally, the high glass transition temperature of FR4 allows it to maintain its structural integrity and electrical properties even under elevated operating temperatures. This thermal stability makes FR4 an excellent choice for applications in automotive electronics, power supplies, and industrial control systems where reliable performance under varying temperature conditions is essential.

Electrical Performance Advantages

The electrical properties of FR4 materials contribute significantly to the overall performance of PCBs. The consistent dielectric constant across a wide frequency range ensures predictable signal propagation, which is crucial for high-speed digital circuits and RF applications. FR4's low dissipation factor minimizes signal losses, allowing for efficient power transmission and signal integrity. Moreover, the high breakdown voltage of FR4 epoxy boards provides excellent insulation between conductive layers, reducing the risk of short circuits and enhancing the overall reliability of the PCB. These electrical performance advantages make FR4 an ideal choice for a wide range of applications, from consumer electronics to sophisticated telecommunications equipment.

Cost-Effectiveness and Versatility

FR4 materials offer an exceptional balance of performance and cost-effectiveness, making them a versatile choice for various PCB applications. The widespread availability and standardized manufacturing processes for FR4 sheets contribute to their relatively low cost compared to more specialized PCB materials. This cost-effectiveness, combined with FR4's excellent properties, allows designers to create high-performance PCBs without incurring excessive material costs. The versatility of FR4 epoxy boards is evident in their use across diverse industries, including aerospace, medical devices, and renewable energy systems. From simple single-layer boards to complex multi-layer designs, FR4 materials continue to be the backbone of modern PCB manufacturing, driving innovation and enabling the development of increasingly sophisticated electronic devices.

Conclusion

FR4 materials have firmly established themselves as the cornerstone of PCB manufacturing, offering a unique combination of electrical, mechanical, and thermal properties that cater to a wide range of electronic applications. The versatility of FR4 sheets, coupled with their cost-effectiveness and reliability, continues to drive innovation in the electronics industry. As technology advances, FR4 epoxy boards evolve to meet the growing demands of miniaturization, high-speed designs, and environmental sustainability. The enduring popularity of FR4 in PCB applications is a testament to its exceptional performance and adaptability, ensuring its relevance in the ever-changing landscape of electronic design and manufacturing.

Contact Us

To learn more about our high-quality FR4 materials and how they can enhance your PCB designs, please don't hesitate to contact us. Our team of experts is ready to assist you in selecting the perfect FR4 epoxy sheet for your specific application needs. Reach out to us today at info@jhd-material.com and take the first step towards optimizing your PCB performance with our superior FR4 products.