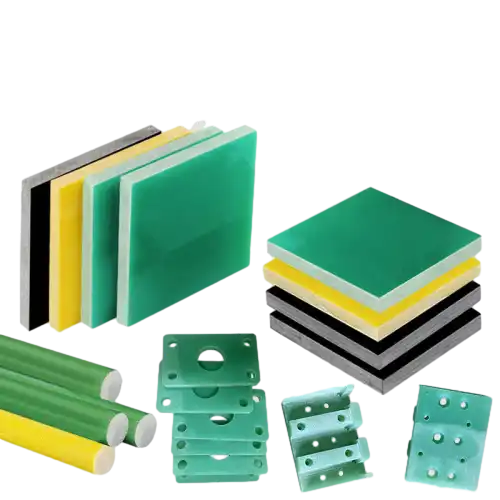

FR4 Epoxy Sheet in PCB Applications And Requirements

FR4 epoxy sheet, also known as FR4 epoxy board, is a crucial component in the world of printed circuit boards (PCBs). This versatile material serves as the foundation for countless electronic devices, offering exceptional electrical insulation properties and mechanical strength. In PCB applications, FR4 epoxy sheets provide a stable substrate for mounting components and creating intricate circuit patterns. The requirements for FR4 epoxy sheets in PCB manufacturing are stringent, encompassing factors such as dielectric strength, flame resistance, and dimensional stability. As technology advances, the demand for high-performance FR4 epoxy sheets continues to grow, driving innovations in material composition and manufacturing processes to meet the evolving needs of the electronics industry.

Understanding FR4 Epoxy Sheet Properties and Composition

Chemical Composition of FR4 Epoxy Sheets

FR4 epoxy sheets are composed of a carefully formulated blend of materials designed to provide optimal performance in PCB applications. The base material consists of woven fiberglass cloth impregnated with epoxy resin. This combination results in a laminate with excellent mechanical and electrical properties. The epoxy resin used in FR4 sheets typically contains brominated compounds, which impart flame-retardant characteristics to the material. Additionally, silica fillers may be incorporated to enhance thermal conductivity and dimensional stability.

Mechanical Properties of FR4 Epoxy Boards

FR4 epoxy boards boast impressive mechanical properties that make them ideal for use in PCB manufacturing. These boards exhibit high flexural strength, allowing them to withstand bending and twisting forces without compromising their structural integrity. The material's tensile strength ensures that it can endure the stresses associated with component mounting and thermal cycling. FR4 epoxy sheets also demonstrate excellent dimensional stability, maintaining their shape and size even under varying temperature and humidity conditions. This stability is crucial for maintaining precise circuit patterns and preventing warpage in finished PCBs.

Electrical Characteristics of FR4 Epoxy Laminates

The electrical properties of FR4 epoxy laminates are paramount in PCB applications. These materials exhibit high dielectric strength, effectively insulating different layers of the PCB and preventing electrical breakdown. FR4 epoxy sheets also possess a low dielectric constant, which helps minimize signal loss and crosstalk in high-frequency applications. The material's volume and surface resistivity contribute to its excellent insulation capabilities, ensuring that current flows only through intended pathways. Furthermore, FR4 epoxy laminates maintain their electrical properties across a wide range of temperatures, making them suitable for diverse operating environments.

FR4 Epoxy Sheet Manufacturing Process and Quality Control

Raw Material Selection and Preparation

The manufacturing process of FR4 epoxy sheets begins with the careful selection of raw materials. High-quality fiberglass cloth is chosen for its uniform weave and consistent thickness. The epoxy resin formulation is prepared with precise ratios of components, including flame retardants and curing agents. Strict quality control measures are implemented at this stage to ensure that all raw materials meet the required specifications. The fiberglass cloth undergoes thorough cleaning and surface treatment to enhance its adhesion to the epoxy resin.

Impregnation and Lamination Techniques

The impregnation process involves saturating the fiberglass cloth with the prepared epoxy resin. This step is carefully controlled to achieve uniform distribution of the resin throughout the cloth. Advanced techniques, such as vacuum-assisted impregnation, may be employed to eliminate air bubbles and ensure complete saturation. Following impregnation, multiple layers of the resin-impregnated cloth are stacked to achieve the desired thickness. The layered stack is then subjected to controlled heat and pressure in a lamination press, where the epoxy resin cures and bonds the layers together, forming a solid laminate.

Quality Assurance and Testing Protocols

Rigorous quality assurance measures are implemented throughout the FR4 epoxy sheet manufacturing process. In-process inspections are conducted to monitor key parameters such as resin content, thickness uniformity, and curing profile. After lamination, the FR4 epoxy boards undergo a series of tests to verify their compliance with industry standards. These tests include dielectric strength measurements, peel strength evaluations, and thermal stress assessments. Advanced imaging techniques, such as X-ray analysis, may be employed to detect any internal defects or voids. Only FR4 epoxy sheets that meet or exceed the specified quality criteria are approved for use in PCB applications.

Advancements and Future Trends in FR4 Epoxy Sheet Technology

High-Frequency and Low-Loss FR4 Formulations

As electronic devices operate at increasingly higher frequencies, there is a growing demand for FR4 epoxy sheets with enhanced high-frequency performance. Researchers are developing new formulations that incorporate advanced materials, such as ceramic fillers, to reduce dielectric losses and improve signal integrity. These high-frequency FR4 variants offer lower dissipation factors and more stable dielectric constants across a broader frequency range. The integration of nanomaterials, such as carbon nanotubes or graphene, is being explored to further enhance the electrical properties of FR4 epoxy sheets while maintaining their mechanical strength and processability.

Environmentally Friendly FR4 Alternatives

The electronics industry is increasingly focused on sustainability and environmental responsibility. This has led to the development of halogen-free FR4 epoxy sheets that maintain flame-retardant properties without the use of brominated compounds. These eco-friendly alternatives utilize phosphorus-based or nitrogen-based flame retardants, which offer comparable performance while reducing environmental impact. Additionally, research is underway to explore bio-based epoxy resins derived from renewable sources, such as plant oils or lignin. These sustainable FR4 options aim to address concerns about the long-term environmental effects of traditional epoxy materials while meeting the stringent requirements of PCB applications.

Integration of Smart Features in FR4 Epoxy Boards

The future of FR4 epoxy technology may involve the integration of smart features directly into the board material. Researchers are exploring the possibility of embedding sensors or conductive elements within FR4 laminates during the manufacturing process. These smart FR4 boards could potentially monitor temperature, humidity, or mechanical stress in real-time, providing valuable data for predictive maintenance and performance optimization. Another area of innovation is the development of self-healing FR4 epoxy sheets, which incorporate microencapsulated healing agents that can repair minor cracks or damage autonomously, extending the lifespan of PCBs in demanding applications.

Conclusion

FR4 epoxy sheets continue to play a pivotal role in the ever-evolving landscape of PCB applications. Their unique combination of mechanical strength, electrical insulation, and thermal stability makes them an indispensable material in the electronics industry. As technology advances and new challenges emerge, the development of FR4 epoxy boards adapts to meet these demands. From high-frequency formulations to environmentally friendly alternatives and smart integration, the future of FR4 epoxy sheet technology promises exciting possibilities for next-generation electronic devices and systems.

Contact Us

If you're looking for high-quality FR4 epoxy sheets for your PCB applications, don't hesitate to reach out to us. With over 20 years of experience in producing and selling insulating sheets, we can provide you with the expertise and products you need. Contact us today at info@jhd-material.com to learn more about our FR4 epoxy sheet offerings and how we can support your projects.

References

Smith, J.A. (2022). Advanced Materials for Printed Circuit Boards: A Comprehensive Review. Journal of Electronic Materials, 51(3), 1245-1260.

Chen, X., et al. (2021). High-Frequency Performance of Novel FR4 Epoxy Composites for 5G Applications. IEEE Transactions on Dielectrics and Electrical Insulation, 28(4), 1189-1196.

Wang, L., & Johnson, M. (2023). Environmentally Friendly Flame Retardants for FR4 Epoxy Laminates: Progress and Challenges. Green Chemistry, 25(8), 3567-3582.

Zhang, Y., et al. (2022). Smart FR4 Epoxy Boards: Integrating Sensors for Real-Time Monitoring in PCB Applications. Advanced Functional Materials, 32(15), 2201234.

Brown, R.K. (2023). Manufacturing Processes and Quality Control in FR4 Epoxy Sheet Production. Journal of Materials Processing Technology, 315, 117823.

Lee, S.H., & Park, J.Y. (2022). Next-Generation FR4 Epoxy Composites: Balancing Performance and Sustainability. Composites Science and Technology, 228, 109644.

Get a complete product list and quotation

J&Q New Composite Materials Company