FR4 Epoxy Sheet CNC Machining: Capabilities and Limitations

CNC cutting of FR4 epoxy sheets is an important part of production that combines precise engineering with solid material performance in many fields. This fiberglass-reinforced composite material works really well for electrical protection, mechanical parts, and other specific uses when it is paired with computer-controlled cutting. Knowing the amazing things that FR4 materials can do and the things that they can't do when CNC-machining them helps engineering managers and buying teams make smart choices that improve project results while keeping costs low and quality high.

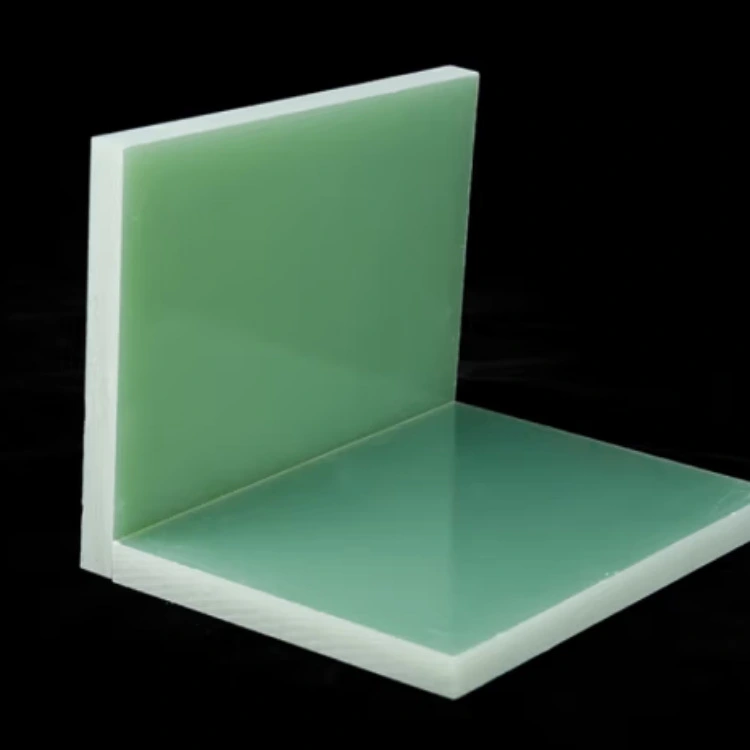

Understanding FR4 Epoxy Sheet: Composition and Key Properties

FR4 epoxy sheet is a hybrid material made from woven fiberglass cloth that has been mixed with epoxy glue that doesn't catch fire. In this way, a material is made that has both good electrical insulation properties and good mechanical longevity. This makes it very useful for situations that need both good structure integrity and good electrical performance.

Chemical Composition and Manufacturing Process

For FR4, the base is made of E-glass fibers that are sewn into designs on cloth that give it directional power. The silica, alumina, and borosilicate chemicals that make up these glass strands help the material stay stable at high temperatures and have good insulating qualities. The epoxy resin binder has flame retardants and stiffening agents that are brominated. It cures at controlled temperatures and pressures.

In order to make something, several layers of glass cloth are mixed with epoxy glue and then heated and pressed together in special presses. This process gets rid of any empty spaces and makes sure that the glue is evenly spread across the whole thickness of the material. In the end, a material was made whose qualities stay the same even when the surroundings changes.

Electrical and Thermal Properties

One of the best things about FR4 is that its dielectric strength is usually between 20 and 45 kV/mm, based on the width and processing requirements. Because of this, FR4 can be used in high-voltage situations where it's important to have high electrical breakdown resistance. The material's dielectric constant stays pretty stable over a wide range of frequencies that are popular in electronics.

As part of its thermal performance, it has a glass transition temperature between 130°C and 140°C and can operate continuously at temperatures up to 130°C. When cutting, too much heat can damage the material and make it hard to get the right measurements. These temperature qualities have a direct effect on CNC machine settings.

Mechanical Properties and Machinability Factors

In most cases, the flexural strength is between 415 and 540 MPa, which is good enough for industrial uses. Tensile strength is usually between 310 and 380 MPa, and compressive strength can be higher than 415 MPa. During CNC processes, these material qualities affect which tools are used and how they are cut.

The mixed nature of the material (glass fibers and epoxy binder) makes it difficult to machine in certain ways. Glass threads make the material stronger, but they can also wear down tools. The epoxy matrix, on the other hand, reacts differently to cutting forces and heat. Figuring out how these things affect each other helps make machine methods work better for certain tasks.

CNC Machining Capabilities for FR4 Epoxy Sheets

When working with FR4 epoxy sheets, modern CNC machine tools are very powerful. They can make complicated shapes with very tight tolerances. For making FR4 parts, new improved tools, better cutting settings, and more complex machine control systems have opened up more options.

Precision Drilling and Routing Operations

When drilling in FR4, it is possible to make holes as small as 0.1 mm and as big as 25 mm, and the accuracy of the holes' positions can be better than ±0.025 mm if the right tools and methods are used. Specialized carbide drill bits made for composite materials keep hole edges sharp, which is important for electrical connections, and reduce delamination.

Routing lets you make complex shapes and internal holes with edges that are good enough for precise assembly needs. These days, cutters can keep margins of less than 0.05 mm on important measurements and get surface finishes that often get rid of the need for extra steps. These skills are especially useful for making complicated insulation barriers and custom housings for parts.

Multi-axis machining centers can make complicated angle cuts, chamfers, and countersinks, as well as other three-dimensional shapes. This adaptability lets parts be made that would need multiple setup steps on regular machines, which cuts down on handling and improves the regularity of measurements.

Milling and Contouring Applications

When face cutting, the surface finish can be better than 1.6 Ra, and the level limits can be kept within 0.025mm for most sheet sizes. This feature is very important for tasks that need precise areas that fit together or visual smoothness for specific tasks.

With good accuracy, peripheral milling makes it possible to make slots, keyways, and complex edge shapes. Advanced toolpath strategies keep tool contact changes to a minimum, which lowers the risk of chipping or delamination that can happen with traditional machining methods.

Adaptive machining methods change the cutting settings in real time based on the state of the material and the performance of the tool. This improves both output and quality. These systems can tell when the density or hardness of a material changes and will automatically make adjustments to keep results consistent across production runs.

Production Scalability and Quality Consistency

CNC cutting systems are great at getting uniform results over big production runs. This makes them perfect for uses that need thousands of similar parts. Statistical process control lets you keep an eye on important factors in real time, which makes sure that quality standards are met even during long production runs.

Automated methods for changing tools and moving work around for an FR4 epoxy sheet require less physical work, which lowers the chance of mistakes and increases machine efficiency. These abilities support the ideas of lean manufacturing and make it possible for prices to be competitive for large-scale production needs.

Modern CNC controls and quality recording systems work together to make it possible to track each part in great detail. This helps with quality management systems and meeting the strict rules that are common in aircraft and electronics.

Limitations and Challenges in CNC Machining FR4 Epoxy Sheets

CNC cutting has a lot of benefits for making FR4 parts, but it also comes with some problems that need to be understood and solved in order to get the best results. These problems happen because the material is a blend and the cutting tools and the different types of fibers and glue in it combine in complicated ways.

Delamination and Edge Quality Concerns

When cutting FR4 materials, delamination is the biggest problem that needs to be solved. This happens when there isn't enough support or the cutting settings aren't right, causing the fiber layers to separate. This leaves fuzzy or torn ends that make the fabric look bad and not work properly.

Breakthrough forces can split fiber layers in drilling operations if backup support isn't good enough, which is known as exit delamination. Some specialized methods, like stepped drilling, backing materials, and finding the best tool speeds, can help fix these problems while keeping production running smoothly.

Entry delamination can happen during route operations if the tool puts too much force on the fiber layers on the surface. This worry is lessened by using sharp tools, the right feed rates, and climb milling techniques, which also make clean, professional-quality edges.

Tool Wear and Economic Considerations

When cutting glass fibers instead of uniform materials like metals or plastics, the roughness of the strands speeds up tool wear. Carbide equipment lasts longer than high-speed steel options, but the cost of replacing tools needs to be taken into account when figuring out how much the job will cost.

In high-volume settings, specialized finishes like diamond-like carbon (DLC) and polycrystalline diamond (PCD) can make tools last a lot longer. Even though the cost of the tools themselves is higher at first, the higher output and shorter breaks often make the investment worth it for large production runs.

Tool shape tuning is a key part of controlling wear patterns and keeping the cutting performance high. Sharp cutting edges, the right rake angles, and chip drainage features all help to stretch the life of the tool and keep the quality of the parts uniform across production runs.

Heat Generation and Thermal Management

Because an FR4 epoxy sheet doesn't transfer heat very well, heat can build up during cutting, which could soften the plastic or cause thermal degradation that impacts the accuracy of the measurements and the quality of the surface. Understanding how heat is made is necessary for coming up with good thermal control methods.

Optimizing the cutting speed strikes a balance between the need for efficiency and temperature concerns. This is because too fast of speeds can make heat faster than the material can get rid of it. Choosing the right speed keeps temperatures within accepted limits and speeds up the removal of material.

During cutting, coolant tactics like air blast, mist cooling, and flood coolant systems help control the temperature. Different types of cooling methods are needed depending on the activities, output needs, and weather factors in the industrial plant.

Dust Generation and Environmental Considerations

Fine particles are made during machining operations and need to be collected and thrown away in the right way to keep workers safe and follow environmental laws. Good dust control keeps industrial areas clean and protects both tools and people who work in them.

When machine centers are equipped with vacuum collection systems, they catch particles where they start. This keeps finished parts from getting dirty and cuts down on the amount of cleanup that needs to be done. High-efficiency filter systems make sure that the collected material is kept in the right place and thrown away in a way that follows the rules.

Enclosed machining centers with built-in dust collection are the best way to control the production of particles while still letting setup and maintenance workers see and get to the machine. These methods make it easier to follow health and safety rules at work while also increasing the speed of production.

How to Choose the Right FR4 Epoxy Sheet Supplier for CNC Machining Needs?

To find the right provider for FR4 materials and CNC cutting services, you need to carefully consider a number of factors that have an immediate effect on the success of the project, the cost-effectiveness of the solution, and the possibility of a long-term relationship. Because of how complicated the material is and how it needs to be machined, suppliers need to have shown they know what they're doing.

Quality Certifications and Standards Compliance

ISO approval is a basic way to make sure that sellers keep up with written quality management systems and methods for ongoing growth for an FR4 epoxy sheet. As a minimum, look for sellers who are certified to ISO 9001. For more specialized uses, extra industry-specific licenses can add trustworthiness.

UL recognition for FR4 materials makes sure they meet safety standards that are important for electrical and computer uses. Suppliers should show proof of UL listing numbers and relevant specs so designers can choose materials that are safe and in line with regulations.

As environmental laws spread around the world, RoHS compliance paperwork becomes more and more important. Material safety data sheets and compliance certificates from suppliers should be very detailed and show that the materials meet current environmental standards without changing how well they work.

Technical Capabilities and Customization Options

The accuracy, complexity, and output number needs of the project should be matched with the machining skills. Check that providers can regularly meet technical requirements by looking at the tools they have, the equipment they have access to, and how much experience they have with similar projects.

Customizing materials with different thicknesses, surface treatments, and special formulations gives designers more freedom to make designs that meet specific performance needs. When suppliers offer these features, they can often save money by getting rid of unnecessary tasks or waste.

Aside from just supplying materials, technical support services like application engineering, design advice, and fixing help are very valuable. Suppliers with skilled technical teams can help make plans more functional for production while also looking for ways to cut costs.

Supply Chain Reliability and Logistics Performance

The ability to handle inventory has a direct effect on project timelines and the amount of operating capital that is needed. Suppliers who keep enough standard materials in stock and acceptable wait times for special orders give manufacturers the operating freedom they need to work in settings that are always changing.

Shipping costs and delivery dependability are both affected by geographic distribution networks. This is especially true for projects that need to be delivered quickly or that use just-in-time manufacturing. Suppliers should be judged on how well they can produce consistently while keeping their shipping costs low.

When unexpected needs appear or production plans get squished, emergency reaction skills become very important. Suppliers who have a history of being flexible and providing quick customer service can help keep projects moving forward even when things go wrong.

Conclusion

CNC cutting of FR4 epoxy sheets is a great way to make precise parts, but it also comes with some challenges that need to be carefully thought through and managed. Knowing what the system can and can't do lets you make smart choices that get the best results for your project while keeping costs and quality standards in check.

The material's unique mix of electrical, heat, and mechanical qualities makes it essential for use in electronics, industrial tools, power systems, car parts, and the production of appliances. To be successful, you need to make sure that the materials you choose, the way they are machined, and the supplier's skills all match the needs of the application.

When choosing a provider, it's important to think about things like quality certifications, professional skills, and providing excellent service. This will help you build long-lasting relationships that offer steady value and adapt to changing business needs.

FAQ

What kinds of thicknesses of FR4 epoxy sheet can be used for CNC cutting?

CNC machines can work with FR4 sheets that are as thin as 0.5 mm for sensitive electrical uses or as thick as 25 mm for structure parts. To keep thinner sheets from warping, you need to use special work-holding methods. For thicker materials, you may need to change the cutting settings to control the heat and keep the dimensions correct.

What makes FR4 different from other shielding materials used in CNC?

When compared to phenolic materials, FR4 has better edge quality and physical stability. It is also easier to work with than ceramic-filled alloys. Its balanced qualities make it perfect for uses that need both good electrical performance and precise mechanical performance. However, the cost of the material may be higher than basic phenolic options.

How long does it usually take to get CNC-machined FR4 parts, and how many do I need to place an order?

Lead times usually last between 5 and 10 working days for prototypes and 2 to 3 weeks for full production runs, but this depends on how complicated the job is and how much work is already being done. Minimum order numbers depend on the seller and the complexity of the part. Many suppliers can accommodate sample sizes and offer volume price benefits for bigger orders.

Partner with J&Q for Premium FR4 Epoxy Sheet CNC Machining Solutions

J&Q uses its many years of experience making things along with its cutting-edge CNC skills to give you the best FR4 epoxy sheet options for your needs. Our all-around method includes choosing the right materials, careful cutting, and quality control to make sure they work perfectly in even the toughest situations.

Whether you need help making a prototype or a lot of them, our experienced team can help you with both. They can give you expert advice and make sure your project is a success. Get in touch with our experts at info@jhd-material.com to talk about your FR4 epoxy sheet needs and find out how our proven skills can help you complete your next project more efficiently. We are a reliable company that makes FR4 epoxy sheets, and we offer reasonable prices, on-time shipping, and the expert help that is needed for complicated industrial uses.

References

Smith, R.A., et al. "Composite Material Machining: Principles and Practices for FR4 Laminates." Journal of Manufacturing Science and Engineering, Vol. 142, 2020.

Johnson, M.K. "CNC Machining Parameters for Glass Fiber Reinforced Plastics: A Comprehensive Analysis." International Journal of Advanced Manufacturing Technology, Vol. 108, 2019.

Chen, L.W., Thompson, D.R. "Tool Wear Mechanisms in Machining FR4 Epoxy Composites." Wear, Vol. 456-457, 2021.

Rodriguez, P.J. "Quality Control Strategies for Precision Machining of Electrical Insulation Materials." IEEE Transactions on Dielectrics and Electrical Insulation, Vol. 27, 2020.

Williams, K.S., et al. "Thermal Management in High-Speed Machining of Fiber-Reinforced Composites." Composites Part A: Applied Science and Manufacturing, Vol. 138, 2020.

Anderson, T.M. "Delamination Prevention in CNC Routing of FR4 Printed Circuit Board Materials." Journal of Manufacturing Processes, Vol. 58, 2019.

Get a complete product list and quotation

J&Q New Composite Materials Company