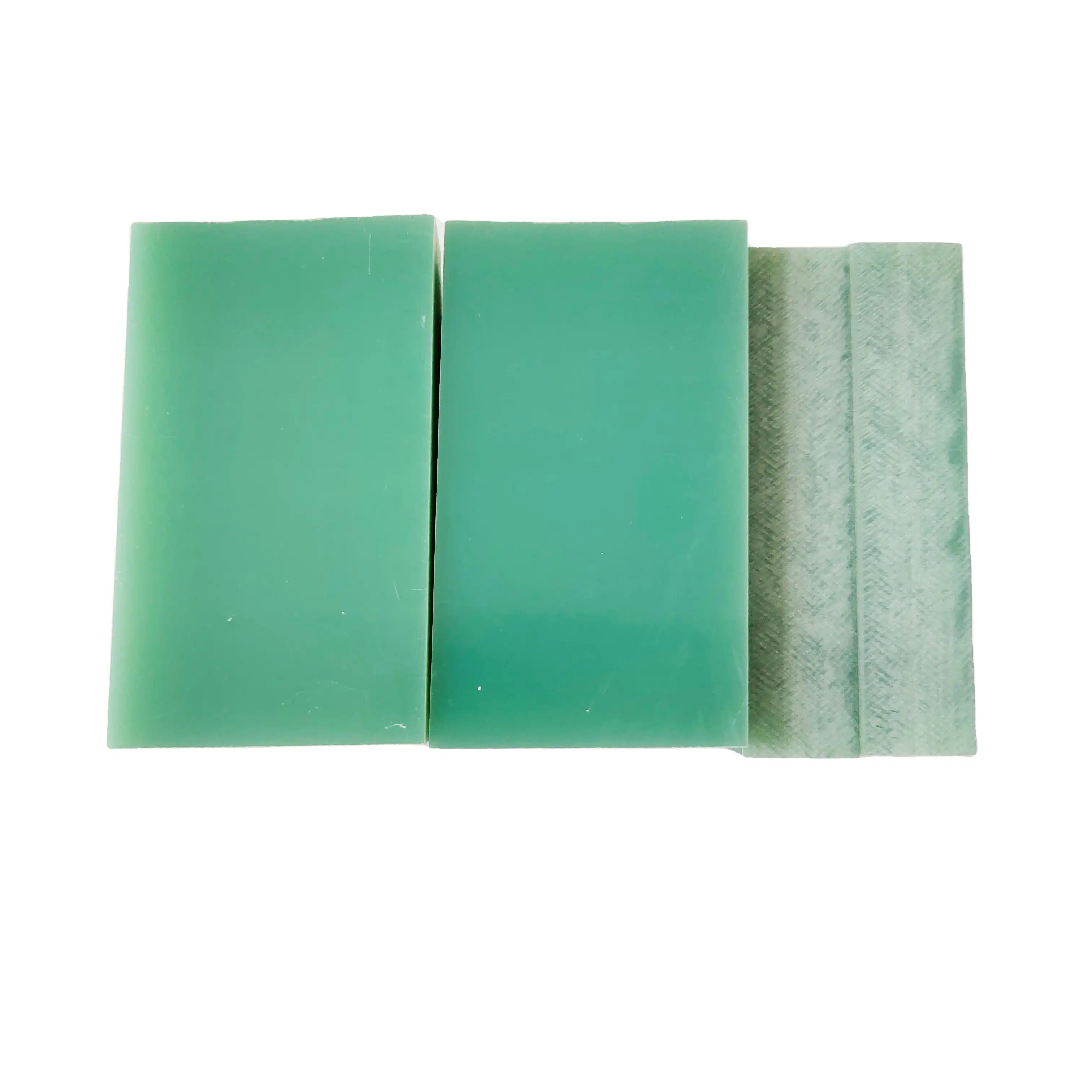

How Do FR4 and G10 Differ in Electrical Insulation Performance?

Dielectric Constant Comparison

The dielectric constant is a fundamental property influencing a material’s effectiveness as an electrical insulator. FR4 sheets generally possess a dielectric constant between 4.2 and 4.8, whereas G10 sheets tend to have slightly higher values, ranging from 4.5 to 5.2. Although the difference appears minimal, it can significantly affect signal propagation, impedance matching, and electromagnetic interference in high-frequency and high-speed electronic circuits. Engineers often consider this variation when designing printed circuit boards (PCBs) to optimize signal integrity and ensure reliable performance in demanding applications.

Dissipation Factor Analysis

The dissipation factor, also referred to as the loss tangent, measures the energy loss of a material when subjected to alternating electric fields. FR4 sheets typically exhibit a lower dissipation factor, around 0.02 at 1 MHz, indicating they dissipate less energy as heat compared to G10 sheets, which range approximately from 0.025 to 0.035 at the same frequency. This lower energy loss makes FR4 preferable for applications requiring higher electrical efficiency and reduced thermal buildup, such as in high-frequency electronic devices and sensitive communication equipment.

Volume Resistivity Evaluation

Volume resistivity quantifies a material’s resistance to electrical current flowing through its interior, which is critical for insulating performance. Both FR4 and G10 sheets demonstrate very high volume resistivity values, commonly between 10^14 and 10^16 ohm-centimeters, underscoring their capability to prevent unwanted electrical conduction. FR4 often shows slightly superior volume resistivity, contributing to marginally better insulation characteristics. This property is essential for ensuring the longevity and reliability of electronic components, especially in environments with high voltage or potential electrical stress.

Dielectric Breakdown Voltage and Material Thickness Factors

Thickness-Dependent Dielectric Strength

The dielectric strength of both FR4 and G10 sheets is not a constant value but varies with the material thickness. Generally, thinner sheets exhibit higher dielectric strength per unit thickness. For instance, a 1mm thick FR4 sheet might have a dielectric strength of 40 kV/mm, while a 5mm thick sheet could show a value closer to 20 kV/mm. This phenomenon is due to the increased probability of defects or weak points in thicker materials.

Environmental Influences on Breakdown Voltage

Environmental factors such as temperature and humidity can significantly affect the dielectric breakdown voltage of both FR4 and G10 materials. High temperatures can reduce the dielectric strength by softening the epoxy resin, while high humidity can lead to moisture absorption, potentially creating conductive paths within the material. FR4, with its slightly superior moisture resistance, tends to maintain its dielectric properties better under challenging environmental conditions.

Long-Term Voltage Stress Effects

Both FR4 and G10 sheets can experience a gradual decrease in dielectric strength when subjected to long-term voltage stress. This phenomenon, known as dielectric aging, can be more pronounced in G10 due to its slightly lower initial dielectric strength. However, the flame-retardant properties of FR4 can provide an additional safety margin in applications where long-term reliability is crucial.

Application Suitability in High-Voltage Environments

Power Distribution Systems

In power distribution systems, where high voltages are common, the choice between FR4 and G10 sheets can be critical. FR4's superior dielectric strength and flame-retardant properties make it an excellent choice for insulation in switchgear, transformers, and other high-voltage equipment. However, G10's better mechanical properties can be advantageous in applications where physical stress is a significant factor alongside electrical insulation requirements.

High-Frequency RF Applications

For high-frequency radio frequency (RF) applications, the dielectric properties of the insulating material become increasingly important. FR4's lower dissipation factor gives it an edge over G10 in these scenarios, as it results in lower signal losses. This makes FR4 sheets a preferred choice for high-frequency PCBs and antenna substrates where maintaining signal integrity is crucial.

Aerospace and Defense Electronics

In aerospace and defense electronics, where reliability under extreme conditions is paramount, both FR4 and G10 sheets find applications. FR4's flame-retardant properties and slightly better dielectric characteristics make it a popular choice for avionics and military communication equipment. However, G10's superior mechanical strength can be advantageous in applications where vibration and physical stress are significant factors.

Conclusion

While both FR4 sheet and G10 sheets offer excellent electrical insulation properties, FR4 sheet generally edges out G10 in terms of dielectric strength and overall performance in high-voltage environments. Its superior flame-retardant properties and slightly better electrical characteristics make it the preferred choice for many electronic applications, especially those involving high frequencies or requiring stringent safety standards. However, G10 remains a viable alternative in scenarios where mechanical strength is a priority or cost considerations are paramount. The choice between FR4 sheet and G10 ultimately depends on the specific requirements of each application, considering factors such as operating voltage, frequency, environmental conditions, and mechanical stress.

Contact Us

For more information about our FR4 and G10 sheets and how they can meet your specific insulation needs, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in selecting the ideal material for your application.