When looking for electrical insulation materials for mining equipment, China has great NEMA CE sheet options that are both of high quality and affordable. As a top manufacturer, J&Q stands out by providing precisely engineered insulation materials that meet the strict needs of mining activities around the world. Our wide selection of NEMA grade electrical laminates offers great dielectric strength, mechanical durability, and temperature resistance, all of which are necessary in harsh mining settings. Chinese suppliers like J&Q have been making things for over 20 years and have strict quality control systems in place. This has made them trusted partners for mining equipment makers looking for cheap but high-performance insulation solutions.

Why Focus on Chinese NEMA CE Sheets for Mining Applications?

The mining business is moving toward Chinese suppliers because they offer many strong benefits. Chinese companies have put a lot of money into high-tech production tools that let them precisely control the thickness of materials and make sure they always have the same qualities, which are important for mining equipment. This new technology makes sure that NEMA CE sheets meet the strict requirements for electrical protection in heavy machinery.

Saving money is another big benefit that doesn't mean lowering quality standards. Chinese manufacturers can offer reasonable prices while keeping the best material properties because they can make a lot of the same thing. This is called economies of scale. This lower cost is especially helpful for mining companies that are in charge of setting up a lot of equipment.

As Chinese makers build out their logistics networks, the reliability of the supply chain has gone up by a huge amount. Many suppliers now offer integrated shipping solutions, which cut down on lead times and make sure that mining companies in remote areas always have access to the materials they need. Manufacturers of mining tools that have to meet tight production deadlines need to be able to keep their supply chains stable.

Essential Selection Criteria for Mining-Grade NEMA CE Sheets

When looking at NEMA CE sheet suppliers, you need to carefully look at a number of performance factors. The main thing to think about is the dielectric strength. For example, breakdown voltages in mining uses must be higher than 15 kV/mm to make sure they can be used safely in high-voltage areas. As important as temperature stability is, it's also important to remember that mine equipment often works in very hot or very cold places.

It is important to carefully look at mechanical qualities, especially flexural strength and impact resistance. Materials used for insulation in mining equipment are constantly vibrating and being stressed mechanically. This means that materials must be durable in order to be reliable over time. Data from tests should show that the product works the same way every time it's loaded and unloaded, just like it would in real life.

Precision in manufacturing has a direct effect on how well equipment works and how it is put together. The ability of NEMA CE sheets to fit together with other parts is affected by their thickness range, surface finish quality, and ability to keep their shape over time. Suppliers should give thorough specifications and quality certifications that show they can keep tolerances low across multiple production batches.

Materials that are certified meet international standards for safety and the environment. UL approval, ROHS compliance, and ISO quality system certifications give customers around the world trust in the performance of the material and its acceptance by regulators.

Top NEMA CE Sheet Products for Mining Equipment

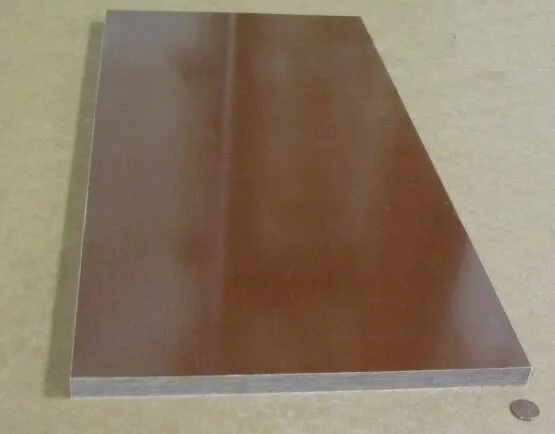

Premium Grade FR4 Glass Epoxy Laminates

For mine equipment uses that need better electrical insulation and mechanical strength, our premium FR4 glass epoxy laminates work really well. These materials have high-temperature epoxy resin systems mixed into multi-layer glass fabric reinforcements. This gives them great dimensional stability even in harsh operating situations.

Key performance features include a dielectric breakdown strength of more than 20 kV/mm, the ability to operate continuously at temperatures up to 130°C, and a bending strength of more than 380 MPa. The glass cloth reinforcement is very good at resisting impacts and keeps the layers from coming apart when they are put under mechanical stress. Since these things are true, FR4 laminates are great for electrical covers in mining equipment, motor terminal boards, and switchgear panels.

Precision in manufacturing makes sure that thickness tolerances stay within ±0.05mm, which allows for accurate machining of complicated part geometries. The material is very easy to cut with a CNC machine, so it can be used to make custom parts quickly and with clean edges that are important for electrical uses. Surfaces that are smooth and don't absorb much water work well in humid mining settings for a long time.

Chemical resistance traits keep things safe from oil, grease, and cleaning solvents that are often used in mining. Because it is made of epoxy resin, the matrix sticks well to metal surfaces and works with a variety of mounting tools. The UL 94 V-0 flame rating makes sure that electrical uses follow fire safety rules.

High-Temperature Phenolic Cotton Laminates

For tough mining jobs, phenolic cotton laminates are a good choice because they have strong mechanical qualities and good electrical insulation. The high-quality cotton cloth reinforcement in these materials is combined with phenolic resin systems that are designed to work well at high temperatures and last a long time mechanically.

These laminates can withstand temperatures up to 150°C for long periods of time, which makes them good for motor parts and thermal shields in mining equipment. The cotton cloth reinforcement is very good at resisting impacts and reducing vibrations, which are very important for mobile mining equipment. The dielectric strength is usually higher than 12 kV/mm, which means it's good enough for most mining uses.

Some of the mechanical strength properties are a compressive strength of over 200 MPa and a high resistance to fatigue under repeated loads. Because of these qualities, it can be used in structural parts like gear wheels, bearing housings, and mechanical spacers that need to be able to both insulate electricity and hold weight. The material's ability to lubricate itself makes moving parts less likely to stick.

Machining properties make it possible to precisely make complicated shapes while keeping the dimensions correct. The cotton reinforcement keeps the tools from wearing down too quickly during CNC operations, which makes it possible to make unique parts at a low cost. For certain uses, surface treatments can improve certain qualities, like how well they resist oil or how well they conduct electricity.

Environmental resistance means that the product works well in dusty conditions and doesn't react badly with most industrial poisons. The phenolic resin system naturally doesn't catch fire and doesn't make a lot of smoke, which are both important safety factors for underground mining uses.

Industrial Grade 3240 Epoxy Boards

Grade 3240 epoxy boards are flexible electrical insulation options that have great electrical qualities and great mechanical performance for use in mining equipment. These materials are reinforced with glass cloth and use special epoxy resin mixtures that work best in industrial settings.

The dielectric strength of these boards is more than 16 kV/mm, and they have great arc protection, which means they can be used in high-voltage switching equipment and transformers. The dielectric constant stays the same over a wide range of frequencies, which makes sure that electrical control systems work reliably. Electrical lines lose less power when the dissipation factor is low.

Temperature performance ranges from -40°C to 130°C, so it can work in a wide range of mining environments. Because the thermal expansion factors are the same as those of common metals, thermal stress in assembled parts is lower. The temperature at which the heat deflects is higher than 145°C, which gives a safety margin for peak working conditions.

Tensile strength of over 280 MPa and good dimensional stability in a range of humidity conditions are some of the mechanical qualities. The glass cloth reinforcement keeps the material from cracking and keeps the performance the same no matter how thick it is. Over and above industry standards, the bond strength between the resin and the cloth ensures long-term dependability.

The quality of the surface meets the precise needs of electrical uses, and the smooth finishes keep dirt from building up. The material can have different surface processes, such as printing and metalization, to help identify parts. Chemical protection includes most of the industrial fluids that are used in mining.

Global Market Analysis and Regulatory Considerations

More and more people want solid electrical insulation materials, which can be seen in the global market for NEMA CE sheets used in mining. Mining equipment makers all over the world have to deal with the same problems when it comes to making sure their machines work well, are safe, and follow safety rules. Because of these shared needs, it's possible to make standard materials that can be used in more than one area.

Different foreign markets have different rules and regulations, but most of them focus on safety, protecting the environment, and meeting performance standards. In Europe, following REACH rules and being good to the environment are very important. In North America, on the other hand, UL recognition and NFPA standards are more important. Cost-effectiveness is often a big deal in Asian markets, but high standards must be kept.

Chinese companies have changed their quality processes to meet a wide range of international standards. A lot of the top suppliers have more than one approval, such as ISO 9001, UL recognition, and different national standards. With this all-around method, they can serve markets around the world with consistent product quality and legal compliance.

Logistics, technical help, and local representation are all things that need to be thought about in the supply chain. Chinese companies that do well set up regional distribution networks and offer technical help to meet customer needs. Language skills and coverage of multiple time zones make it easier to communicate with buyers from other countries.

Purchasing Recommendations and Strategic Considerations

To successfully purchase NEMA CE sheets, you need to do more than just look at the supplier's basic material specs. Building long-term relationships with dependable providers brings stability and lets you work together to create products for specific uses. Long-term supply security is affected by how stable a supplier's finances are, how much they can produce, and how well-developed their quality system is.

Protocols for quality assurance should include testing of new materials, audits of suppliers, and ongoing tracking of performance. Setting clear specs and acceptance criteria stops quality problems and makes sure that materials always work the same way. Regularly talking to suppliers lets you spot possible problems early and work together to solve them.

Inventory management methods find a balance between keeping supplies safe and keeping costs low. Keeping strategic amounts of inventory on hand protects against supply problems and keeps carrying costs as low as possible. The ability for suppliers to predict the future and the flexibility of their production help with just-in-time shipping and efficient inventory planning.

Technical support services are very useful because they help with applications, material choices, and fixing problems. Suppliers with a wide range of professional skills can help with product development and improve the performance of materials for specific uses.

Industry Trends and Future Outlook

The mining equipment business is always changing to become more efficient, safer, and less harmful to the earth. These trends increase the need for high-tech insulation materials that work better and don't harm the earth. As mining equipment becomes more automated and electric, it opens up new markets for specialized electrical insulation options. Chinese companies spend money on research and development to keep up with these new needs while keeping their prices low.

Conclusion

Chinese manufacturers have proven to be reliable sources for the mining equipment business around the world when it comes to getting high-quality NEMA CE sheets. When mining equipment makers around the world combine advanced manufacturing skills with competitive pricing and thorough quality systems, they offer very good value. Long-term relationships that work well are made possible by carefully choosing suppliers based on their technical skills, quality certifications, and customer service. For your mining machinery insulation needs, J&Q is the best example of Chinese manufacturing excellence. They offer high-quality materials, technical know-how, and a reliable supply chain.

FAQs

What about NEMA CE sheets makes them good for use on mining equipment?

NEMA CE sheets are very good at blocking electricity and have the mechanical strength that mining settings need. Because they can handle high and low temperatures, vibration, and dirt from the environment, they are perfect for electrical parts in big machinery. The materials keep working well even in the tough conditions that are common in mining activities.

How do Chinese companies make sure that their products are always of high quality for people around the world?

Some of the best Chinese manufacturers use full quality management systems that include ISO certification, advanced testing methods, and statistical process control. Consistent material properties are made sure of through regular audits, batch testing, and constant monitoring. To meet global standards, many suppliers also keep up with foreign certifications like UL recognition.

What kinds of width differences are possible with NEMA CE sheets made in China?

Professional Chinese makers can usually keep thickness tolerances to within 0.05 mm for standard grades and 0.02 mm for precision uses. These tight tolerances are possible because of modern production equipment and quality control methods. They are needed for precision mining equipment parts.

J&Q: Your Trusted NEMA CE Sheet Manufacturer Partner

J&Q offers the best NEMA CE sheet options in the business, designed to work with mining equipment. We are the best supply partner for you because we can make anything, have strict quality control systems, and have a lot of experience serving markets around the world. We know what mining equipment makers around the world need because we've been making things for over 20 years and trading with other countries for over 10 years.

Our combined logistics services cover the whole process, from production to delivery, so your operations can be sure of a smooth supply chain. Advanced testing centers check the properties of materials and make sure that the quality is the same in every batch of production. Technical support teams help with applications and make sure that unique materials are developed to meet your needs.

Quality certifications, such as UL recognition and ROHS compliance, show that we follow foreign rules. We stay at the top of the global market as a seller of NEMA CE sheets by investing in new production technology and quality systems all the time.

Email us at info@jhd-material.com to talk about the insulation needs of your mining equipment and find out how our high-quality materials can improve the performance and dependability of your equipment.