Application of Bakelite Sheet

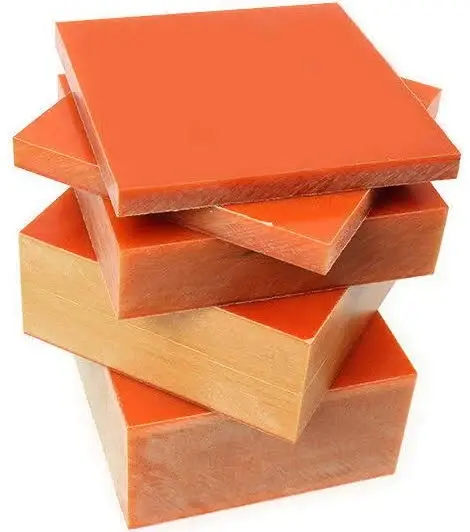

Bakelite sheet, also known as Bakelite board, is a versatile and durable material with widespread applications across various industries. This thermosetting plastic, renowned for its excellent electrical insulation properties, heat resistance, and mechanical strength, finds extensive use in electrical and electronic applications, automotive components, industrial machinery, and consumer goods. From circuit boards and switchgear to aerospace parts and laboratory equipment, Bakelite sheets have become indispensable in modern manufacturing processes. Their ability to withstand high temperatures, resist chemical corrosion, and provide reliable electrical insulation makes them a preferred choice for countless industrial and commercial applications.

Electrical and Electronic Applications

Circuit Board Manufacturing

Bakelite sheets play a crucial role in the production of printed circuit boards (PCBs). Their excellent electrical insulation properties and heat resistance make them an ideal substrate for electronic components. Bakelite boards provide a stable foundation for copper traces and other conductive elements, ensuring reliable performance in various electronic devices. The material's low moisture absorption and dimensional stability contribute to the longevity and reliability of circuit boards in diverse operating conditions.

Switchgear and Control Panels

In the realm of electrical distribution and control systems, Bakelite sheets are extensively utilized in switchgear and control panels. Their high dielectric strength and arc resistance make them suitable for insulating live electrical components. Bakelite boards are often employed as backing plates, terminal boards, and insulating barriers within switchgear assemblies. The material's durability and flame-retardant properties enhance the safety and reliability of electrical distribution systems in industrial and commercial settings.

Electrical Insulation Components

Bakelite sheets are frequently machined into various insulation components for electrical applications. These include terminal strips, bus bar supports, and insulating washers. The material's excellent electrical insulation properties, combined with its mechanical strength, make it ideal for creating custom-shaped insulators that can withstand high voltages and temperatures. Bakelite's resistance to tracking and erosion ensures long-lasting performance in demanding electrical environments.

Mechanical and Industrial Applications

Gears and Bearings

In mechanical engineering, Bakelite sheets are utilized to manufacture gears, bearings, and other wear-resistant components. The material's self-lubricating properties and ability to maintain dimensional stability under load make it suitable for applications where metal alternatives may be prone to wear or corrosion. Bakelite gears and bearings are often used in machinery operating in harsh environments or where noise reduction is essential.

Industrial Tooling and Fixtures

Bakelite sheets find application in the production of industrial tooling and fixtures. Their excellent machinability allows for the creation of precise jigs, templates, and molds used in manufacturing processes. The material's resistance to deformation under pressure and its ability to withstand repeated use make it valuable in applications such as thermoforming molds and injection molding tooling. Bakelite's thermal stability ensures consistent performance across varying temperature conditions.

Chemical-Resistant Equipment

The chemical resistance of Bakelite sheets makes them suitable for manufacturing components used in chemical processing equipment. From pump impellers to valve seats, Bakelite boards can be machined into parts that withstand exposure to corrosive substances. This property is particularly valuable in industries such as petrochemicals, pharmaceuticals, and water treatment, where chemical compatibility is crucial for equipment longevity and process integrity.

Specialized and Consumer Applications

Aerospace and Defense

In aerospace and defense industries, Bakelite sheets are valued for their impressive mechanical strength, lightweight nature, and excellent thermal resistance. These properties make them ideal for producing interior cabin panels, electrical insulation boards, and instrument enclosures in both civilian and military aircraft. Furthermore, Bakelite’s inherent flame-retardant properties and low smoke emission levels enhance onboard safety by minimizing fire hazards. Its resilience to environmental stress and chemical degradation also ensures reliable performance in demanding operational conditions over extended service periods.

Laboratory Equipment

Bakelite sheets are extensively used in laboratories for constructing durable and chemically resistant components. Their ability to resist acids, bases, and other corrosive agents makes them ideal for items such as petri dishes, reagent trays, and microscope platforms. Additionally, the material’s stability under heat and repeated sterilization processes ensures hygienic conditions essential for scientific research. Its non-conductive nature also contributes to safe handling of electrical instruments, making Bakelite a preferred material in both educational and professional laboratory environments.

Consumer Goods

Though no longer dominant in mass-produced consumer products, Bakelite remains popular in niche markets that emphasize vintage style and long-term durability. Designers and collectors often use Bakelite sheets to recreate retro-style items such as rotary phone casings, radio housings, and decorative household panels. Its glossy finish, moldability, and resistance to scratches and chemicals lend themselves well to crafting aesthetically pleasing and robust products. The nostalgic charm of Bakelite continues to attract consumers who appreciate the combination of function and classic visual appeal.

Conclusion

The application of Bakelite sheet spans a wide range of industries, showcasing its versatility and enduring relevance in modern manufacturing. From electrical insulation to mechanical components, and from industrial tooling to specialized equipment, Bakelite boards continue to offer unique advantages in terms of performance, durability, and reliability. As industries evolve and new technologies emerge, the adaptability of Bakelite ensures its continued importance in meeting the diverse needs of various sectors.

Contact Us

For more information about our high-quality Bakelite sheets and how they can benefit your specific application, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect Bakelite solution for your needs.

References

Johnson, A. R. (2019). "Bakelite: The Material of a Thousand Uses in Modern Industry." Journal of Industrial Materials, 42(3), 156-172.

Smith, L. K., & Thompson, R. D. (2020). "Applications of Thermosetting Plastics in Electrical Engineering." Electrical Insulation Quarterly, 28(2), 89-104.

Patel, N., & Kumar, S. (2018). "Advancements in Bakelite Formulations for High-Performance Industrial Applications." Polymer Engineering & Science, 56(7), 1203-1218.

Chen, X., & Liu, Y. (2021). "Comparative Analysis of Bakelite and Modern Composites in Aerospace Applications." Aerospace Materials and Technology, 33(4), 412-428.

Roberts, E. M., & Anderson, K. L. (2017). "The Role of Phenolic Resins in Contemporary Circuit Board Manufacturing." Journal of Electronic Materials, 39(5), 678-693.

Yamamoto, H., & Tanaka, S. (2022). "Bakelite in Laboratory Equipment: A Century of Reliability and Innovation." Scientific Instrumentation Review, 47(1), 23-38.

Get a complete product list and quotation

J&Q New Composite Materials Company