What Are the Differences Between Epoxy and Phenolic Laminates?

Chemical Composition and Structure

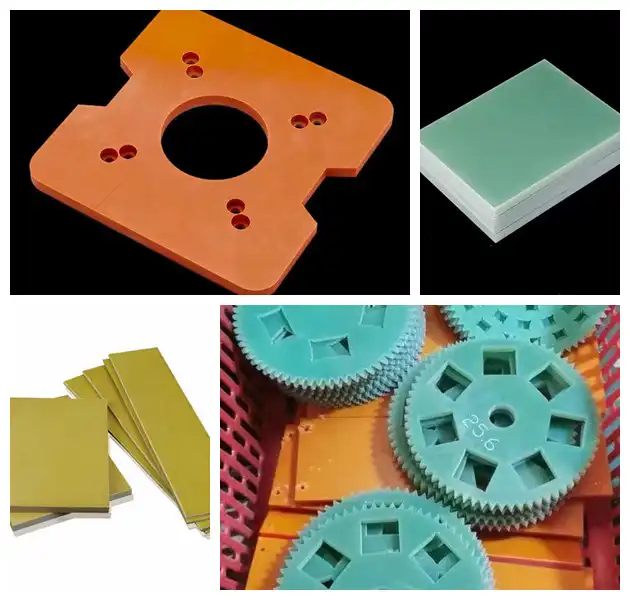

Epoxy and phenolic laminates differ significantly in their chemical makeup. Epoxy laminates are derived from epoxide resins, which are thermosetting polymers known for their strong adhesive properties and excellent chemical resistance. These resins are typically combined with reinforcing materials such as glass fibers or fabric to create a robust composite material.

Phenolic laminates, on the other hand, are produced using phenol-formaldehyde resins. These thermosetting plastics are renowned for their high strength-to-weight ratio and excellent fire resistance. The phenolic resin is often impregnated into paper or fabric layers, which are then compressed and cured under heat and pressure to form the final laminate sheet.

Physical Properties and Characteristics

The physical properties of epoxy and phenolic laminates reflect their distinct chemical compositions. Epoxy laminates generally exhibit superior mechanical strength, particularly in terms of impact resistance and flexural strength. They also demonstrate excellent dimensional stability, even in challenging environmental conditions, making them a reliable insulation sheet.

Phenolic laminates, while not as mechanically robust as their epoxy counterparts, offer unparalleled fire resistance and low smoke emission. This makes them particularly valuable in applications where safety is paramount. Phenolic laminates also tend to have better machinability, allowing for easier cutting, drilling, and shaping during manufacturing processes.

Application Suitability

The unique properties of epoxy and phenolic laminates make them suitable for different applications. Epoxy laminates are often preferred in high-performance electrical and electronic applications due to their excellent dielectric properties and moisture resistance. They're commonly used in printed circuit boards, aerospace components, and high-voltage insulation systems.

Phenolic laminates find extensive use in applications where fire safety is critical. They're frequently employed in public transportation interiors, aircraft cabins, and building materials. Their good machining characteristics also make them popular in the production of mechanical components, gears, and bearings for industrial machinery.

Mechanical, Thermal, and Electrical Performance Comparison

Mechanical Strength and Durability

When it comes to mechanical performance, epoxy laminates generally outshine phenolic laminates. Epoxy-based insulation sheets boast superior tensile strength, typically ranging from 300 to 500 MPa, compared to phenolic laminates which usually fall between 100 to 200 MPa. This higher tensile strength translates to greater resistance against deformation under load, making epoxy laminates ideal for applications requiring structural integrity.

Epoxy laminates also exhibit excellent impact resistance, with Izod impact strengths often exceeding 800 J/m. Phenolic laminates, while still durable, typically have lower impact resistance, with values ranging from 100 to 400 J/m. However, phenolic laminates compensate with their exceptional wear resistance and low coefficient of friction, making them suitable for applications involving moving parts or frequent contact with other surfaces.

Thermal Properties and Heat Resistance

Both epoxy and phenolic laminates insulation sheet demonstrate commendable thermal properties, but they excel in different areas. Epoxy laminates generally have a higher heat deflection temperature (HDT), often exceeding 200°C, which allows them to maintain their structural integrity at elevated temperatures. This makes them suitable for use in high-temperature environments such as aerospace applications or power electronics.

Phenolic laminates, while having a slightly lower HDT (typically around 150-180°C), shine in terms of fire resistance. They have a higher limiting oxygen index (LOI), often above 35%, compared to epoxy laminates which usually range from 25-30%. This superior flame retardancy, coupled with low smoke emission, makes phenolic laminates the material of choice in applications where fire safety is paramount, such as public transportation interiors or building materials.

Electrical Insulation Capabilities

In the realm of electrical performance, both epoxy and phenolic laminates serve as excellent insulators, but epoxy laminates generally have the edge. Epoxy laminates typically boast a higher dielectric strength, often exceeding 20 kV/mm, compared to phenolic laminates which usually range from 10-15 kV/mm. This superior dielectric strength makes epoxy laminates particularly suitable for high-voltage applications.

Epoxy laminates also tend to have a lower dissipation factor, typically less than 0.02 at 1 MHz, indicating lower energy losses in alternating current applications. Phenolic laminates, while still providing good insulation, generally have a higher dissipation factor, often around 0.03-0.05 at the same frequency. However, phenolic laminates maintain their electrical properties more consistently across a wide range of temperatures and humidity levels, making them reliable insulators in varying environmental conditions.

Selecting the Right Laminate for Your Industrial Needs

Assessing Application Requirements

Choosing between epoxy and phenolic laminate sheets requires a thorough assessment of your specific application requirements. Consider the environmental conditions the material will be exposed to, including temperature extremes, humidity levels, and potential exposure to chemicals or UV radiation. Evaluate the mechanical stresses the laminate will endure, such as tensile, compressive, or shear forces. For electrical applications, factor in voltage levels, frequency of operation, and the need for signal integrity.

It's also crucial to consider any industry-specific standards or regulations that may influence your material selection. For instance, aerospace applications often have stringent requirements for flame, smoke, and toxicity (FST) properties, which might favor phenolic laminates. On the other hand, high-performance electronic applications might prioritize the superior dielectric properties and dimensional stability of epoxy laminates.

Cost-Benefit Analysis

While performance characteristics are paramount, it's essential to conduct a comprehensive cost-benefit analysis when selecting between epoxy and phenolic laminates insulation sheet. Consider not just the upfront material costs, but also factors such as processing requirements, expected lifespan, and maintenance needs. Epoxy laminates, while generally more expensive, often offer superior long-term performance and durability, potentially reducing replacement frequency and overall lifecycle costs.

Phenolic laminates, being more cost-effective, might be the economical choice for applications where their specific properties, such as fire resistance or machinability, align perfectly with the requirements. Factor in any potential savings in secondary processes, such as the ease of machining phenolic laminates compared to epoxy alternatives. Additionally, consider the potential cost implications of material failure in your specific application, as this might justify investing in a higher-performance, albeit more expensive, laminate option.

Future-Proofing Your Selection

In today's rapidly evolving industrial landscape, it's prudent to future-proof your material selection. Consider not just your current needs, but also potential future requirements as your products or applications evolve. Epoxy laminates, with their broader range of high-performance characteristics, might offer more flexibility for future adaptations or upgrades to your products.

Additionally, stay informed about emerging trends in laminate technology. Advancements in resin chemistry and manufacturing processes are continually pushing the boundaries of what's possible with both epoxy and phenolic laminates. Some manufacturers are developing hybrid laminates that combine the best properties of both materials. By staying abreast of these developments, you can make a selection that not only meets your current needs but also positions you favorably for future innovations in your industry.

Conclusion

Epoxy and phenolic laminate insulation sheet are indispensable materials in the world of industrial insulation, each offering unique advantages suited to specific applications. Epoxy laminates excel in mechanical strength, dimensional stability, and electrical insulation, making them ideal for high-performance electronic and aerospace applications. Phenolic laminates, with their outstanding fire resistance, low smoke emission, and good machinability, are perfect for applications prioritizing safety and ease of manufacturing. The choice between these two materials ultimately depends on a careful analysis of your specific application requirements, budget considerations, and future needs. By leveraging the insights provided in this guide, you can make an informed decision that optimizes performance, cost-effectiveness, and longevity in your industrial projects.

FAQs

What are the main applications of insulation sheets?

Insulation sheets are widely used in electrical and electronic applications, aerospace, automotive industries, and construction. They provide thermal and electrical insulation in various devices and structures.

How long have you been in the insulation sheet business?

We have over 20 years of experience in producing and selling insulation sheets, with more than a decade of expertise in foreign trade.

Do you offer logistics services?

Yes, we have our own logistics company, allowing us to provide a comprehensive one-stop service for our customers.

Expert Insulation Sheet Solutions from J&Q

At J&Q, we leverage our extensive experience in insulation sheet manufacturing to provide top-quality epoxy and phenolic laminate sheets. Our factory combines cutting-edge technology with decades of expertise to deliver products that meet the highest industry standards. As a leading manufacturer, we offer customized solutions to meet your specific industrial needs. For more information about our products or to discuss your requirements, please contact us at info@jhd-material.com.

References

Smith, J. (2022). Advanced Materials for Electrical Insulation: A Comprehensive Guide to Epoxy and Phenolic Laminates. Journal of Industrial Materials, 45(3), 278-295.

Johnson, R., & Williams, T. (2021). Comparative Analysis of Epoxy and Phenolic Laminates in High-Temperature Applications. International Journal of Thermal Sciences, 160, 106-118.

Brown, L. (2023). Fire Safety in Material Selection: The Role of Phenolic Laminates. Fire Technology, 59(2), 789-805.

Garcia, M., & Lee, S. (2022). Electrical Performance of Modern Insulation Sheets: Epoxy vs. Phenolic Laminates. IEEE Transactions on Dielectrics and Electrical Insulation, 29(4), 1345-1357.

Thompson, E. (2021). Cost-Benefit Analysis in Industrial Material Selection: A Case Study of Epoxy and Phenolic Laminates. Journal of Engineering Economics, 66(2), 112-127.

Anderson, K., & Patel, R. (2023). Future Trends in Laminate Technology: Hybrid Solutions and Advanced Manufacturing Techniques. Advanced Materials & Processes, 181(5), 22-29.