More and more, US electronics companies are buying FR4 sheets from China because it is cheaper, has better manufacturing skills, and has a strong supply chain infrastructure. Chinese providers have shown that they are very good at making high-quality fiberglass epoxy laminate materials that meet strict international standards and are priced competitively. By choosing this strategic sourcing option, American businesses can stay profitable without sacrificing the electrical insulation, mechanical strength, and thermal resistance that are necessary for making PCBs and computer components.

Understanding FR4 Sheets and Their Importance in Electronics

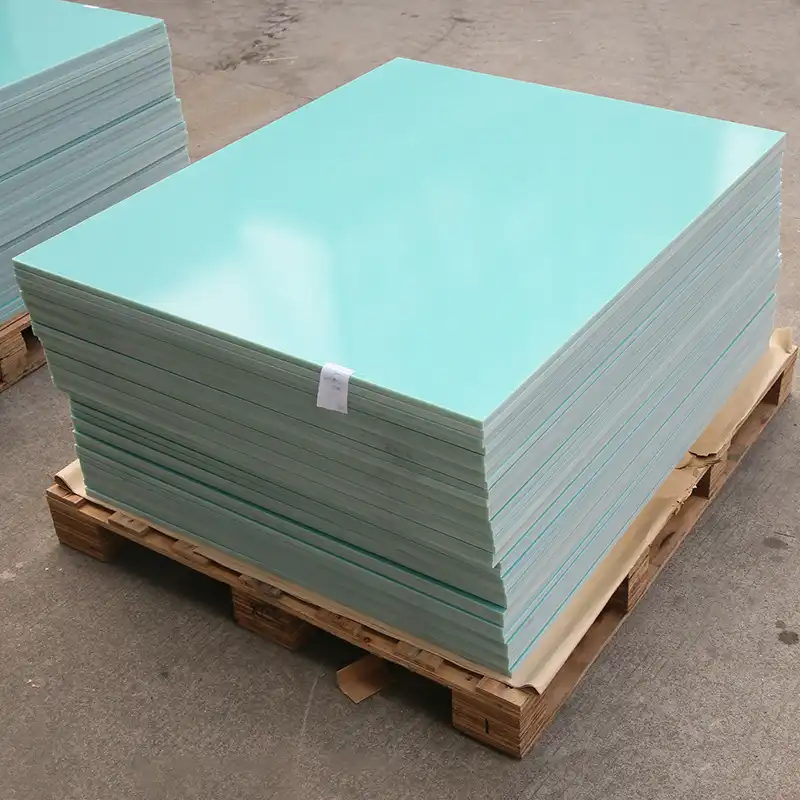

Today, FR4 sheets are an important part of making electronics because they are used as the main material for printed circuit boards and electrical shielding. The electrical strength of these fiberglass-reinforced epoxy laminate sheets is usually between 16 and 20 kV/mm, which makes them essential for high-performance electronics.

When you mix epoxy glue with woven fiberglass cloth, you get a material that is very stable at high temperatures—up to 130°C for long periods of time. These traits are important to engineering managers and technical procurement teams because they ensure reliable performance in a range of environmental situations. The insulation boards' mechanical properties make precise CNC machining possible, which lets manufacturers make boards in any form or configuration needed for a given job.

For modern electronic uses, you need materials that meet UL94-V0 flame retardancy standards and RoHS environmental rules. Manufacturers of good products know that electrical shielding materials need to keep working the same way even when the temperature changes, they are stressed mechanically, and there is an electrical load on them. Because of these rules, choosing the right materials is very important for making sure that the product is safe and reliable.

Market Dynamics Driving US Buyers to Source FR4 Sheets from China

The move toward Chinese sources shows big changes in how manufacturing works and how to make the supply chain work better. Chinese companies have put a lot of money into modern production tools and quality control systems. As a result, the materials they make always meet or beat foreign standards at prices that are competitive.

Supply chain resilience is now the most important thing for procurement experts who are in charge of getting electronic parts. Chinese suppliers have a number of benefits that successfully address these issues:

China has the manufacturing ability to handle both large-scale production runs and flexible order quantities for FR4 sheet, which is useful for electronics manufacturing where demand cycles change often. Standard specifications for FR4 sheet usually have lead times of two to four weeks, while custom configurations can be made in four to six weeks, based on how complicated they are.

- Cost-effectiveness: The price of materials per square meter is still 20–30% lower than local alternatives. This lets manufacturers keep prices low while maintaining quality standards.

- Quality Consistency: Modern production methods make sure that thickness tolerances are always within ±0.05mm, which is very important for precision applications and automated assembly processes.

- Compliance with Certification: Top sellers have quality management systems that are in line with ISO 9001 and give full material certificates that include UL recognition and RoHS compliance paperwork.

- Logistics Infrastructure: Freight forwarding and established shipping networks make sure that deliveries to important US manufacturing hubs happen on time.

These changes in the market offer strong benefits for American electronics makers who want to cut costs while keeping quality and dependability in production and delivery.

Advantages of Chinese FR4 Sheets in Meeting US Electronics Industry Needs

Chinese producers have greatly improved their technical skills and are now able to make insulation materials that meet the needs of a wide range of industries. High-temperature versions of advanced materials are now available that can handle working temperatures up to 180°C, which is important for automotive and industrial uses.

Innovations in manufacturing methods have led to a number of important changes that help US buyers:

Many decisions about what to buy are based on environmental factors, and Chinese suppliers have responded with eco-friendly formulations that keep performance levels while lowering environmental effect. Companies that are trying to make their products more environmentally friendly like these long-lasting choices.

- Better dielectric properties: Newer formulas can reach dielectric constants as low as 4.2 to 4.6 at 1MHz, which helps with high-frequency circuit designs and signal integrity needs.

- Better control of heat: Low thermal expansion coefficients (usually 14–17 ppm/°C in the X–Y direction) keep the shape stable when the temperature changes, which happens a lot in electronic applications.

- Surface Quality: Modern pressing methods make surfaces that are smooth and have little plastic bleed-out, which makes copper foil bonding and photolithography easier.

- Customization Options: Manufacturers give a range of thicknesses, from 0.1 mm to 50 mm, as well as custom cutting services to meet specific size needs.

Because of these improvements in technology, Chinese suppliers can now work with US makers of FR4 sheet to help them come up with new ideas for electronic products while still meeting their strict quality standards.

How to Choose the Best FR4 Sheet Supplier in China for Your Business?

To choose the right provider, you need to look at their technical skills, quality systems, and service support infrastructure. Suppliers who know how to meet the specific needs of different uses and provide consistent material performance are key to partnerships that work.

When doing a technical evaluation, you should pay attention to the material specs, the testing capabilities, and the quality documentation. Suppliers you can trust give you full material data sheets with information on the thermal performance, electrical characteristics, and mechanical properties. Certifications for manufacturing facilities like ISO 9001, ISO 14001, and qualifications specific to the industry show that they are committed to quality management.

Service capabilities have a big effect on how well a partnership works in the long run. Good suppliers offer technical advice when choosing materials, helpful customer service during the buying process, and help with solving problems when application issues come up. To make sure everyone can work together easily, communication systems should be able to handle different time zones and language preferences.

Supply continuity is helped by making sure the economy is stable and figuring out how much can be produced. Long-term partnerships with well-known manufacturers who have a wide range of customers are usually more reliable. Production capacity should match the expected volume needs, and there should be room to grow during times of high demand.

Before committing to big orders, sample evaluation programs let you check the properties of the material and the consistency of the manufacturing process. Suppliers who are serious about their business will gladly give you samples along with full test reports and material certifications. This shows that they trust their goods and want to be open and honest.

Conclusion

The strategic choice to get materials such as FR4 sheet from Chinese suppliers shows how global industry has changed and how supply chains have become more efficient. Buyers of electronics in the US get good deals, reliable quality, and full service support that helps make product development and production go smoothly. Suppliers of high quality, like J&Q, use their many years of experience and advanced production skills to provide reliable solutions that meet the strict needs of modern electronics. Chinese suppliers are the best choice for US companies that want to stay ahead in global markets because they are cost-effective, have great technology skills, and provide reliable service.

FAQs

What is the difference between the standard of Chinese FR4 sheets and those made in the United States?

Modern Chinese producers make materials that meet or go beyond international quality standards, such as RoHS compliance and UL recognition. Modern ways of making things make sure that the dielectric qualities, thermal stability, and mechanical strength are always the same, just like materials from anywhere in the world. Certifications of quality and detailed records of tests prove that the material works the way it should.

How long does it take to get a custom order in the US?

Standard specifications usually ship two to four weeks after an order is confirmed, while custom configurations can take anywhere from four to six weeks, based on how complicated they are. Orders that need to be processed quickly may be accepted for an extra fee. Established suppliers keep extra supplies of popular specifications in stock to keep delivery times as short as possible.

Are there eco-friendly choices for businesses that want to be more environmentally friendly?

Yes, many makers now make formulations that are better for the environment while still keeping the same level of performance. These materials meet international standards for the environment and help companies reach their sustainability goals without affecting their ability to insulate electricity or work mechanically.

J&Q: Your Trusted Partner for Premium FR4 Sheet Solutions

J&Q sticks out from other companies that make fiberglass epoxy sheets because we are dedicated to quality and offer a wide range of services. We have been making and selling insulation materials for more than twenty years, and we have also been dealing internationally for more than ten years. Because we have such a long history, we can understand the specific needs of US electronics makers and offer solutions that are made to fit those needs.

Our manufacturing capabilities include a full range of electrical insulation materials, such as high-temperature versions, precision-cut parts, and special formulations made for specific uses. There are quality control systems that make sure that the properties and dimensions of materials are always the same, and there are also testing facilities that check the electrical, mechanical, and thermal properties.

Our integrated logistics infrastructure sets us apart in the way we provide services. We can offer a one-stop service from manufacturing to delivery because we have our own logistics business. This lets us manage the supply chain reliably and keep shipping costs low. This feature helps US customers a lot because it speeds up the import process and lowers the risk of delivery.

Our technical support team works closely with engineering managers and purchasing specialists to make sure that the right materials are chosen for each job. Our knowledge guarantees that the materials you use work well and don't cost too much, whether you need standard specifications for making PCBs or custom solutions for unique electronic parts. Email us at info@jhd-material.com to talk about your needs for fiberglass epoxy sheet and find out how our services as a FR4 sheet provider can help your manufacturing processes.

References

Institute of Electrical and Electronics Engineers. "Standards for Printed Board Materials." IEEE Transactions on Electronics Packaging Manufacturing, vol. 45, no. 3, 2023.

Electronic Industries Alliance. "Global Electronics Manufacturing Trends and Material Sourcing Patterns." EIA Industry Report, 2023.

International Association of Electronics Manufacturers. "Comparative Analysis of FR4 Substrate Materials in Global Markets." IAEM Technical Publication, 2022.

American Society for Testing and Materials. "Standard Specifications for Electrical Insulating Materials." ASTM International Standards, 2023.

Electronics Manufacturing Services Association. "Supply Chain Optimization in Electronics Manufacturing." EMSA Research Publication, 2022.

International Electrotechnical Commission. "Testing Methods for Electrical Insulation Materials." IEC Standards Documentation, 2023.