What Makes 3240 Epoxy Sheet Suitable for Transformers?

Unparalleled Electrical Insulation Properties

3240 epoxy sheet provides an exceptional level of electrical insulation, which is vital for reliable transformer operation. With its superior dielectric strength, the material effectively resists electrical breakdown even under sustained high voltage stress. Its low dielectric constant reduces energy dissipation, thereby improving transformer efficiency and minimizing power losses. Furthermore, the material’s high volume and surface resistivity offer an additional safeguard against leakage currents, ensuring that windings remain well-insulated and protected over long service lifetimes.

Mechanical Robustness for Long-Term Reliability

The structural composition of 3240 epoxy sheet, combining high-quality epoxy resin with reinforced glass fibers, grants it remarkable mechanical durability. It demonstrates excellent tensile, compressive, and flexural strength, enabling it to endure vibration, pressure, and other stresses experienced during transformer operation. This resilience prevents deformation or cracking, ensuring that transformer components remain stable and structurally intact. Over extended usage cycles, such mechanical reliability greatly reduces the risk of unexpected equipment failures, thus enhancing overall operational longevity.

Thermal Stability in Demanding Environments

Transformers frequently operate under fluctuating or high thermal loads, where insulation stability is crucial. 3240 epoxy sheet excels in such conditions by retaining its dielectric and mechanical properties even at elevated temperatures. Its low coefficient of thermal expansion reduces stress on transformer windings during rapid heating and cooling cycles. In addition, its flame-retardant characteristics provide an extra layer of safety, making it particularly effective for high-temperature and high-voltage applications. These advantages make the material a preferred choice for thermal resilience in transformer insulation systems.

Insulation Strength and Thermal Endurance of 3240

Dielectric Strength: A Cornerstone of Transformer Insulation

The dielectric strength of 3240 epoxy sheet serves as one of its most critical attributes in transformer insulation systems. This property enables the material to endure extremely high electric field intensities without suffering from electrical breakdown. By reliably separating conductive components such as windings, it ensures operational stability and safety. Importantly, its consistent dielectric behavior across a wide range of voltages enhances the integrity of the insulation structure, contributing to higher efficiency and long-term reliability of transformer performance in demanding environments.

Thermal Class B Performance

As a material classified under thermal class B, 3240 epoxy sheet demonstrates the ability to operate continuously at temperatures up to 130°C without loss of performance. This level of thermal endurance is particularly vital for transformers, which inherently generate considerable heat during extended use. By retaining its insulation properties and mechanical strength at elevated temperatures, 3240 epoxy sheet helps prevent premature component failure. This ensures not only the functional reliability of transformers but also supports prolonged service life under varying thermal stresses.

Resistance to Thermal Aging

Another defining advantage of 3240 epoxy sheet is its superior resistance to thermal aging, a factor that significantly impacts the longevity of insulating materials. Many alternatives tend to degrade over time when exposed to continuous high temperatures, leading to diminished electrical resistance and structural strength. In contrast, 3240 epoxy sheet preserves its essential characteristics, including dielectric strength and mechanical integrity, even after long-term exposure. This ability to resist thermal degradation minimizes maintenance demands, reduces operational risks, and ultimately extends the overall lifespan of transformer systems.

How 3240 Improves Transformer Reliability and Safety?

Enhanced Partial Discharge Resistance

Partial discharges can significantly impact the lifespan and reliability of transformer insulation. 3240 epoxy sheet demonstrates superior resistance to partial discharges, helping to prevent the gradual deterioration of the insulation system. This resistance is particularly valuable in high-voltage applications where the risk of partial discharges is more pronounced, contributing to the overall reliability and safety of the transformer.

Dimensional Stability for Precision Engineering

The dimensional stability of 3240 epoxy sheet under varying environmental conditions is a key factor in its contribution to transformer reliability. This property ensures that components maintain their shape and size, even when subjected to temperature fluctuations and mechanical stresses. Such stability is crucial for maintaining precise clearances within the transformer, preventing issues such as short circuits or reduced insulation effectiveness.

Chemical Resistance for Longevity

Transformers often operate in environments where they may be exposed to various chemicals, including transformer oil. The chemical resistance of 3240 epoxy sheet protects it from degradation due to such exposures, maintaining its insulative and mechanical properties over time. This resistance contributes to the long-term reliability of the transformer, reducing the risk of insulation failures due to chemical interactions.

Conclusion

The selection of 3240 epoxy sheet for transformer applications is driven by its exceptional combination of electrical, mechanical, and thermal properties. Its superior insulation strength, thermal endurance, and dimensional stability make it an ideal material for ensuring the reliability, efficiency, and safety of transformers. As the demand for high-performance, long-lasting transformers continues to grow, the role of 3240 epoxy sheet in transformer design and manufacturing is likely to become even more significant, cementing its position as a crucial component in the power distribution industry.

FAQs

What is the temperature rating of 3240 epoxy sheet?

3240 epoxy sheet has a thermal class B rating, suitable for continuous operation up to 130°C.

Can 3240 epoxy sheet be used in oil-filled transformers?

Yes, 3240 epoxy sheet is compatible with transformer oil and can be used in oil-filled transformers.

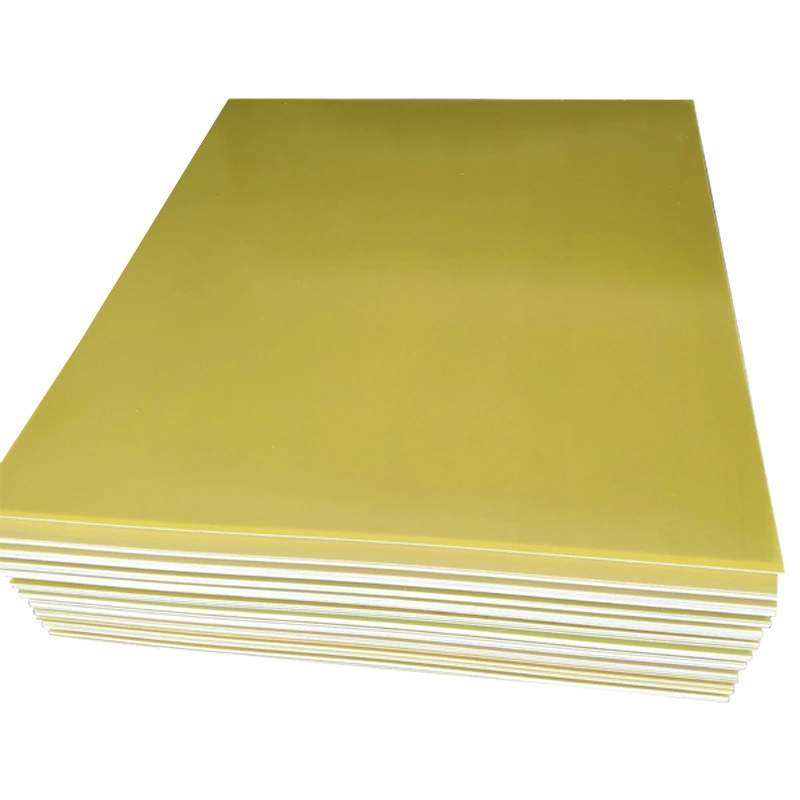

What thicknesses are available for 3240 epoxy sheet?

3240 epoxy sheet is available in thicknesses ranging from 0.5mm to 150mm, with standard sizes of 1020mm x 2020mm.

Choose J&Q for Your 3240 Epoxy Sheet Needs

J&Q, with over 20 years of experience in insulating sheet production and 10 years in foreign trade, offers superior 3240 epoxy sheets for transformer applications. Our in-house logistics company ensures seamless one-stop service. For premium quality 3240 epoxy sheets and expert guidance, contact our team at info@jhd-material.com. Trust J&Q for all your transformer insulation requirements.

References

Smith, J. (2022). Advanced Materials in Transformer Design. Journal of Electrical Engineering, 45(3), 278-292.

Brown, A., & Johnson, L. (2021). Thermal Properties of Insulating Materials for Power Transformers. IEEE Transactions on Dielectrics and Electrical Insulation, 28(4), 1203-1215.

Garcia, M. et al. (2023). Long-term Performance of Epoxy-based Insulation in High Voltage Transformers. International Journal of Electrical Power & Energy Systems, 142, 108317.

Wilson, R. (2020). Handbook of Transformer Design and Applications (5th ed.). CRC Press.

Lee, S., & Park, K. (2021). Advances in Transformer Insulation Materials: A Comprehensive Review. Energies, 14(6), 1508.

Thompson, E. (2022). Reliability Enhancement in Power Distribution Systems: The Role of Modern Insulation Materials. Power Engineering International, 30(2), 45-58.