How Do FR4 and G10 Compare in Electrical Insulation?

Dielectric Properties and Voltage Breakdown

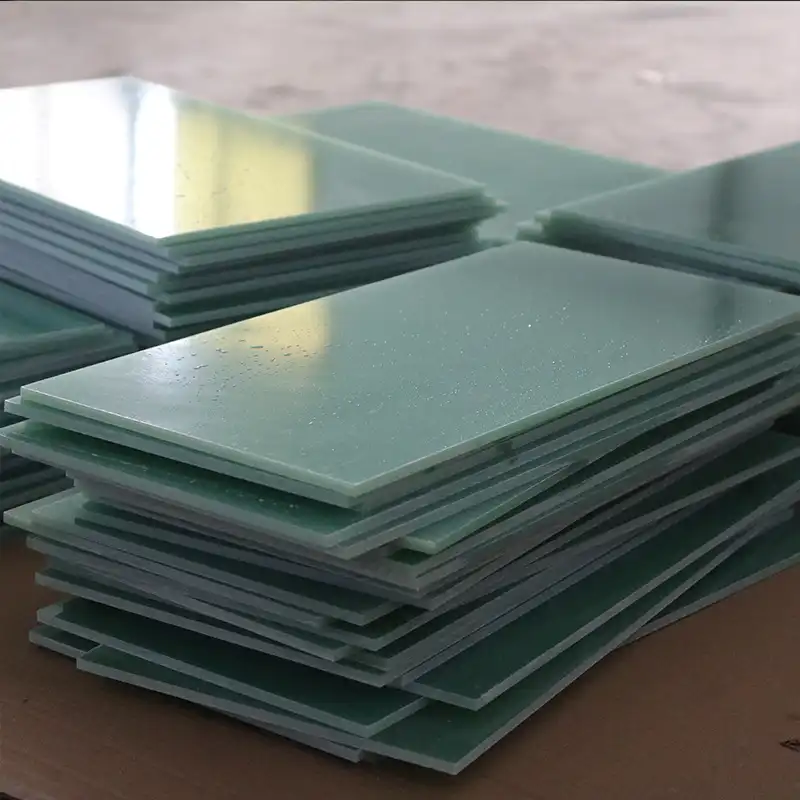

FR4 and G10 sheets both exhibit excellent dielectric properties, making them ideal choices for electrical insulation in PCBs. FR4 typically has a slightly higher dielectric constant, ranging from 4.2 to 4.8, compared to G10's 4.0 to 4.5. This difference, while small, can be significant in high-frequency applications where precise impedance control is crucial. Both materials offer impressive voltage breakdown strength, with FR4 generally capable of withstanding up to 50 kV/mm and G10 slightly lower at around 40 kV/mm. These values ensure reliable insulation in most PCB designs, protecting against electrical arcing and short circuits.

Frequency Response and Signal Integrity

In terms of frequency response, FR4 and G10 sheets perform similarly at lower frequencies. However, as frequencies increase, FR4 tends to maintain better signal integrity due to its more consistent dielectric properties across a broader frequency range. This characteristic makes FR4 the preferred choice for high-speed digital circuits and RF applications. G10, while still suitable for many applications, may exhibit slightly higher signal losses at very high frequencies, which could impact the overall performance of sensitive RF circuits.

Moisture Absorption and Insulation Resistance

Both FR4 and G10 sheets demonstrate low moisture absorption rates, which is crucial for maintaining consistent electrical properties over time. FR4 typically absorbs slightly less moisture than G10, with absorption rates of 0.1% and 0.2% respectively. This difference becomes important in high-humidity environments or applications where long-term reliability is paramount. The lower moisture absorption of FR4 translates to more stable insulation resistance over time, ensuring consistent electrical performance even under challenging environmental conditions.

Durability and Thermal Resistance in PCB Environments

Mechanical Strength and Flex Resistance

G10 sheets generally exhibit superior mechanical strength compared to FR4. With a flexural strength of approximately 480 MPa, G10 outperforms FR4, which typically has a flexural strength of around 340 MPa. This enhanced strength makes G10 an excellent choice for applications requiring high durability and resistance to mechanical stress. However, FR4's strength is more than adequate for most PCB applications, and its slightly lower rigidity can be advantageous in designs that require some degree of flexibility to withstand vibration or thermal cycling.

Temperature Stability and Glass Transition

Both FR4 and G10 materials demonstrate good thermal stability, but their performance differs at extreme temperatures. FR4 has a glass transition temperature (Tg) ranging from 130°C to 180°C, depending on the specific formulation. G10, on the other hand, typically has a slightly lower Tg, around 130°C to 140°C. This difference becomes crucial in high-temperature applications, where FR4's higher Tg allows it to maintain its mechanical and electrical properties more effectively. For applications involving frequent thermal cycling or exposure to elevated temperatures, FR4's superior thermal stability can contribute to increased longevity and reliability of the PCB.

Chemical Resistance and Environmental Durability

FR4 and G10 sheets both offer excellent resistance to a wide range of chemicals, making them suitable for use in harsh environments. However, FR4 generally exhibits slightly better overall chemical resistance due to its more advanced epoxy resin formulation. This enhanced resistance protects against degradation from exposure to solvents, acids, and other corrosive substances that PCBs might encounter during manufacturing or in their operational environment. The superior chemical resistance of FR4 contributes to its longer lifespan and reliability in diverse applications, from consumer electronics to industrial control systems.

Cost-Effectiveness and Industry Preferences in PCB Materials

Manufacturing Costs and Availability

FR4 sheets have become the industry standard for PCB manufacturing, largely due to their cost-effectiveness and widespread availability. The production process for FR4 has been optimized over decades, resulting in lower manufacturing costs compared to G10. This cost advantage is particularly significant for high-volume production runs. Additionally, the ubiquity of FR4 in the PCB industry means that it's readily available from numerous suppliers, often with shorter lead times than G10. This availability can be crucial for meeting tight production schedules and responding quickly to market demands.

Processing and Fabrication Considerations

When it comes to processing and fabrication, FR4 holds several advantages over G10. FR4's slightly softer composition makes it easier to drill and machine, reducing tool wear and processing time. This characteristic is particularly beneficial in the production of complex multilayer PCBs, where numerous vias and intricate routing patterns are required. FR4 also tends to produce cleaner edges when cut, which can be important for certain high-precision applications. While G10 is still machinable, its higher hardness can lead to increased tool wear and potentially longer processing times, factors that can impact overall production costs and efficiency.

Industry Standards and Regulatory Compliance

FR4's flame-retardant properties give it a significant edge in meeting industry standards and regulatory requirements. Many electronic products must comply with strict fire safety regulations, and FR4's inherent flame resistance helps manufacturers meet these standards without additional treatments or modifications. This compliance is particularly crucial in industries such as aerospace, automotive, and consumer electronics, where safety is paramount. While G10 can be made flame-retardant through additional treatments, FR4's built-in flame resistance simplifies the compliance process and reduces potential regulatory hurdles. This factor has contributed significantly to FR4's dominance in the PCB industry and its preference among manufacturers across various sectors.

Conclusion

In the quest for the ideal PCB material, both FR4 sheets and G10 sheets offer compelling advantages. FR4's superior flame retardancy, excellent electrical properties, and cost-effectiveness make it the preferred choice for most PCB applications. Its widespread adoption has led to optimized manufacturing processes and easier regulatory compliance. However, G10's superior mechanical strength and stability in certain conditions ensure its continued relevance in specialized applications. Ultimately, the choice between FR4 and G10 should be based on a careful evaluation of your specific project requirements, balancing factors such as electrical performance, mechanical needs, environmental conditions, and cost constraints.

Contact Us

For more information about FR4 and G10 sheets, or to discuss your specific PCB material needs, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to help you make the best choice for your project.