Key International And Regional Certification Requirements

IEC Standards for Electrical Insulation

The International Electrotechnical Commission (IEC) plays a pivotal role in setting global standards for Bakelite sheet quality in electrical applications. IEC 60893 specifically addresses the requirements for industrial rigid laminated sheets based on thermosetting resins for electrical purposes. This standard delineates the classification system, requirements, and test methods for Bakelite and similar materials. Compliance with IEC standards ensures that Bakelite sheets meet international safety and performance benchmarks.

ASTM Standards for Material Properties

ASTM International, formerly known as the American Society for Testing and Materials, provides another crucial set of standards for Bakelite sheet quality. ASTM D709 covers standard specification for laminated thermosetting materials, including Bakelite sheets. This standard outlines the physical, mechanical, and electrical properties that these materials must possess to be suitable for electrical applications. Adherence to ASTM standards is often a prerequisite for product acceptance in many markets.

Regional Certifications and Their Impact

Regional certification bodies also play a significant role in regulating Bakelite sheet quality. In Europe, CENELEC harmonizes electrotechnical standards across member countries. The CE marking, based on compliance with relevant European directives, is often required for Bakelite sheets used in electrical products sold within the European Union. Similarly, Underwriters Laboratories (UL) in North America provides safety certifications that are widely recognized and often mandatory for electrical components, including those made from Bakelite sheets.

Electrical, Mechanical, And Thermal Performance Criteria

Dielectric Strength and Insulation Resistance

Dielectric strength is a critical parameter for Bakelite sheets used in electrical applications. Standards typically require a minimum dielectric strength, measured in volts per mil or kilovolts per millimeter, to ensure the material can withstand high voltages without breakdown. Insulation resistance, another crucial property, is measured in megohms and must meet specified thresholds to prevent current leakage. These electrical properties are fundamental to the safety and reliability of Bakelite sheets in electrical systems.

Mechanical Strength and Dimensional Stability

Mechanical performance criteria for Bakelite sheets include flexural strength, tensile strength, and impact resistance. These properties ensure that the material can withstand physical stresses encountered in electrical applications. Dimensional stability is also crucial, as Bakelite sheets must maintain their shape and size under varying environmental conditions. Standards specify allowable tolerances for thickness, flatness, and other dimensional characteristics to ensure consistent performance in electrical components.

Thermal Resistance and Flammability Ratings

Thermal performance is another critical aspect of Bakelite sheet quality for electrical use. Standards define maximum operating temperatures and thermal index ratings, which indicate the material's ability to maintain its properties over time at elevated temperatures. Flammability ratings, such as those specified by UL 94, are essential for safety in electrical applications. These ratings categorize materials based on their burning behavior and self-extinguishing properties, ensuring that Bakelite sheets meet fire safety requirements in electrical equipment.

Testing Protocols To Ensure Quality Compliance

Electrical Property Testing Methodologies

Testing protocols for electrical properties of Bakelite sheets are rigorously defined in international standards. Dielectric strength tests involve applying increasing voltage across a sample until breakdown occurs. Insulation resistance tests measure the material's ability to resist current flow under a specified voltage. These tests are conducted under controlled environmental conditions to ensure reproducibility and reliability of results. Manufacturers must employ specialized equipment and follow precise procedures to accurately assess the electrical performance of Bakelite sheets.

Mechanical and Physical Property Evaluation

Mechanical property testing involves subjecting Bakelite sheet samples to various stresses and measuring their response. Flexural strength is typically assessed using a three-point bending test, while tensile strength is evaluated through elongation tests. Impact resistance is often measured using Izod or Charpy impact testers. Dimensional stability is checked through precise measurements before and after exposure to different environmental conditions. These tests ensure that Bakelite sheets meet the mechanical requirements necessary for reliable performance in electrical applications.

Environmental and Aging Tests

To simulate real-world conditions and assess long-term performance, Bakelite sheets undergo various environmental and aging tests. These may include exposure to high humidity, temperature cycling, and ultraviolet radiation. Accelerated aging tests help predict the material's behavior over extended periods. Water absorption tests are crucial for applications where moisture resistance is essential. Additionally, chemical resistance tests ensure that Bakelite sheets can withstand exposure to oils, solvents, and other substances commonly encountered in electrical environments.

Conclusion

The quality of Bakelite sheets for electrical use is governed by a complex network of international and regional standards. These regulations ensure that the material meets stringent electrical, mechanical, and thermal performance criteria. By adhering to these standards and undergoing rigorous testing protocols, manufacturers can produce Bakelite sheets that deliver consistent, reliable performance in a wide range of electrical applications. As technology advances and safety requirements evolve, these standards continue to adapt, maintaining the relevance and reliability of Bakelite sheets in the modern electrical industry.

FAQs

What are the key properties that make Bakelite sheets suitable for electrical applications?

Bakelite sheets excel in electrical insulation, heat resistance, and mechanical strength, making them ideal for various electrical components.

How often are standards for Bakelite sheet quality updated?

Standards are typically reviewed and updated every 3-5 years to reflect technological advancements and changing industry needs.

Can Bakelite sheets be customized to meet specific electrical requirements?

Yes, manufacturers can modify Bakelite formulations to enhance certain properties, such as improved heat resistance or higher dielectric strength, to meet specific application needs.

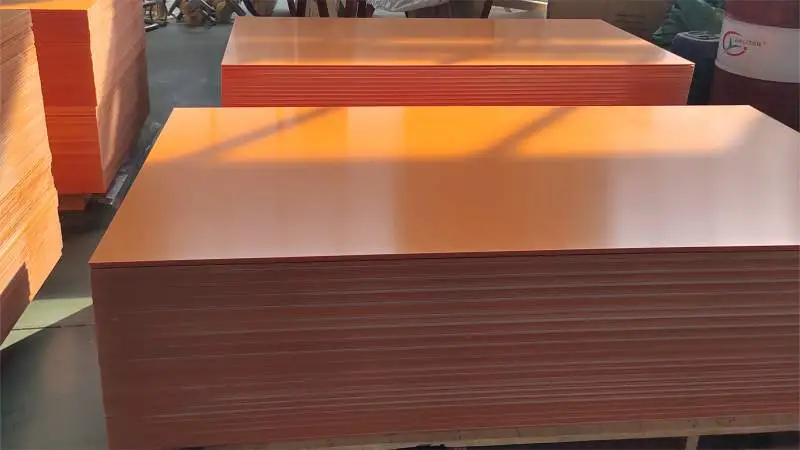

Choose J&Q for High-Quality Bakelite Sheets and Exceptional Service

J&Q, with over 20 years of experience in producing and selling insulating sheets, is your trusted partner for high-quality Bakelite sheets. Our extensive knowledge in foreign trading and collaboration with numerous domestic and international companies ensures we provide superior products and services. With our own logistics company, we offer a seamless one-stop solution for all your Bakelite sheet needs. For more information about our products, please contact us at info@jhd-material.com.

References

International Electrotechnical Commission. (2018). IEC 60893-3-2:2018 Specification for industrial rigid laminated sheets based on thermosetting resins for electrical purposes.

ASTM International. (2017). ASTM D709-17 Standard Specification for Laminated Thermosetting Materials.

Underwriters Laboratories. (2019). UL 94: Standard for Tests for Flammability of Plastic Materials for Parts in Devices and Appliances.

European Committee for Electrotechnical Standardization. (2020). CENELEC EN 60893 series: Specification for industrial rigid laminated sheets based on thermosetting resins for electrical purposes.

Institute of Electrical and Electronics Engineers. (2016). IEEE Std 1-2000 IEEE Recommended Practice - General Principles for Temperature Limits in the Rating of Electrical Equipment and for the Evaluation of Electrical Insulation.

International Organization for Standardization. (2019). ISO 178:2019 Plastics — Determination of flexural properties.