What is Phenolic Cotton Laminated Sheet Used For?

Phenolic cotton laminated sheets are versatile, durable materials widely used across various industries due to their exceptional mechanical strength, electrical insulation properties, and resistance to wear and tear. These sheets, often referred to as phenolic cotton cloth laminate sheet 3026, are primarily employed in applications requiring robust insulation and structural integrity, such as electrical equipment, automotive components, and machinery parts. Their ability to withstand high pressure, heat, and chemical exposure makes them indispensable in manufacturing insulating components like gears, bearings, and bushings. Additionally, their cost-effectiveness and adaptability ensure they meet the needs of global manufacturers seeking reliable materials for demanding environments.

Understanding the Basics of Phenolic Cotton Laminated Sheets

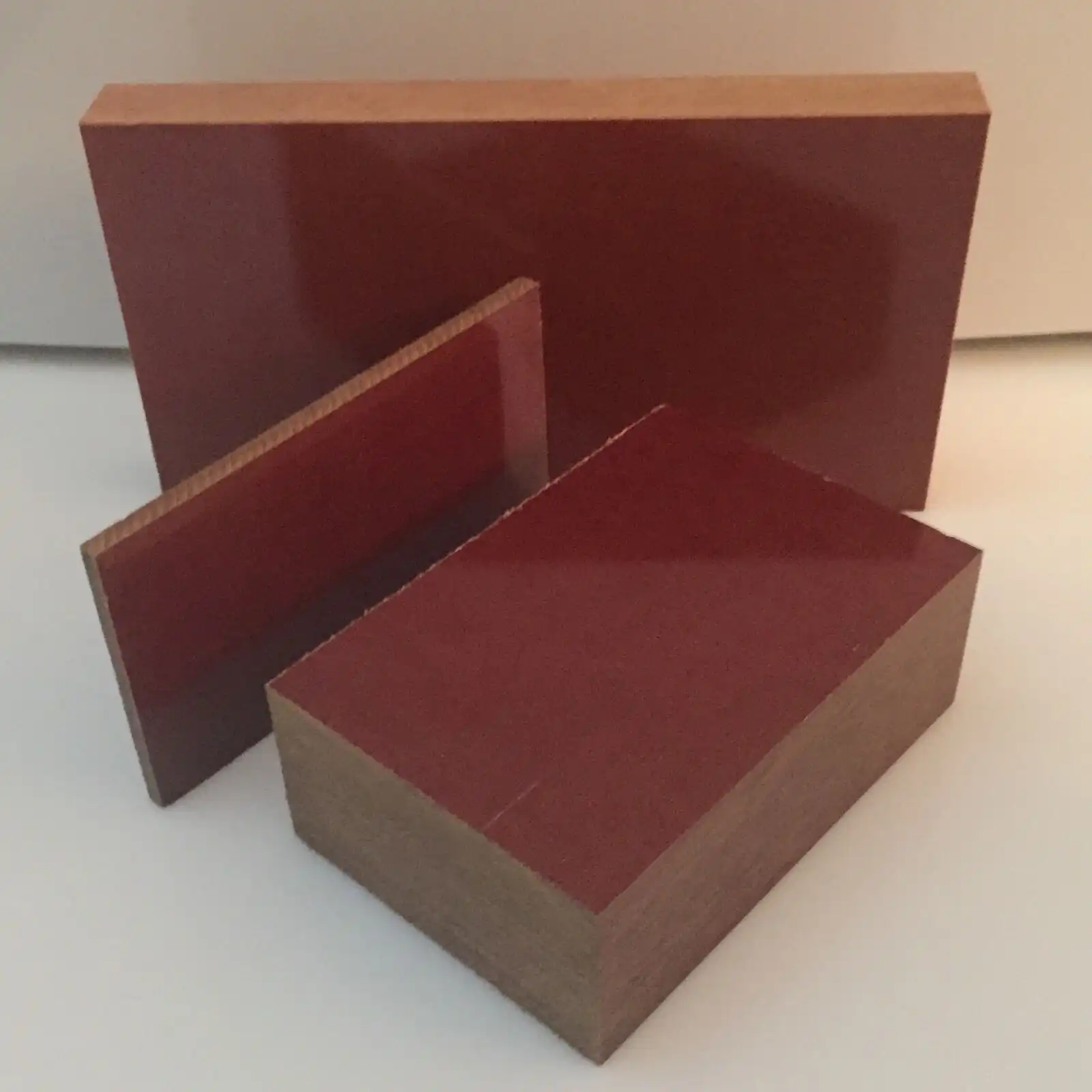

Composition and Manufacturing Process

Phenolic cotton laminated sheets are engineered by impregnating layers of cotton fabric with phenolic resin, a thermosetting polymer renowned for its resilience. This composite is then subjected to intense heat and pressure, creating a rigid, cohesive material. The cotton fabric provides mechanical strength, while the phenolic resin enhances insulation and resistance to environmental stressors. This meticulous process results in a product that balances durability with functionality, making it a staple in industries requiring high-performance materials. Manufacturers often tailor the thickness and grade of these sheets to suit specific applications, ensuring versatility across global markets.

Key Properties That Define Its Utility

What sets phenolic cotton laminated sheets apart is their remarkable array of properties. These sheets exhibit superior dielectric strength, making them ideal for electrical insulation. Their mechanical robustness allows them to endure heavy loads and abrasive conditions, while their thermal stability ensures performance in high-temperature settings. Additionally, they resist moisture, chemicals, and corrosion, extending their lifespan in harsh environments. This unique combination of traits positions phenolic cotton cloth laminate sheet 3026 as a go-to material for engineers and designers seeking reliability without exorbitant costs. Its adaptability to machining processes further enhances its appeal, allowing for precision crafting of intricate components.

Comparing Phenolic Cotton Sheets to Other Insulating Materials

When evaluating insulating materials, phenolic cotton laminated sheets often outshine alternatives like fiberglass or pure plastic laminates. Unlike fiberglass, which may excel in thermal resistance but lacks mechanical toughness, phenolic cotton sheets offer a balanced profile of strength and insulation. Compared to pure plastic laminates, they provide better wear resistance and dimensional stability under stress. This makes them a pragmatic choice for applications where both electrical and mechanical performance are paramount. While more advanced composites may offer specialized benefits, the cost-effectiveness and proven track record of phenolic cotton sheets make them a preferred option for manufacturers worldwide, particularly in high-volume production settings.

Applications of Phenolic Cotton Laminated Sheets Across Industries

Electrical and Electronics Sector

In the realm of electrical engineering, phenolic cotton laminated sheets are indispensable for their insulating prowess. They are commonly used to fabricate insulating supports, terminal boards, and switchgear components, where preventing electrical arcing is critical. Their ability to maintain dielectric integrity under high voltage ensures safety and reliability in transformers, motors, and circuit breakers. Global manufacturers of electrical equipment rely on these sheets to meet stringent safety standards, particularly in environments where exposure to moisture or heat could compromise performance. The adaptability of phenolic cotton cloth laminate sheet 3026 to precision cutting and drilling further enhances its utility in crafting bespoke electrical components.

Mechanical and Automotive Engineering

Beyond electrical applications, phenolic cotton laminated sheets shine in mechanical and automotive engineering. Their robustness makes them ideal for producing gears, bearings, and bushings that endure constant friction and pressure. In automotive manufacturing, these sheets are used in clutch plates and brake systems, where their resistance to wear and thermal degradation ensures longevity. Their ability to be machined into complex shapes allows engineers to design components that meet exacting specifications, reducing downtime and maintenance costs. For global manufacturers, the durability and cost-efficiency of these sheets make them a cornerstone of high-performance mechanical assemblies, from heavy machinery to precision instruments.

Specialized Uses in Harsh Environments

Phenolic cotton laminated sheets also find niche applications in environments that demand exceptional resilience. In the oil and gas industry, they are used to create insulating spacers and supports that withstand corrosive chemicals and extreme temperatures. Similarly, in marine engineering, their resistance to moisture and salt exposure makes them suitable for components in shipbuilding. Aerospace manufacturers leverage their lightweight yet sturdy nature for non-structural parts, ensuring safety without adding unnecessary weight. These specialized uses highlight the versatility of phenolic cotton sheets, positioning them as a material of choice for industries operating under the most arduous conditions.

Benefits and Considerations When Using Phenolic Cotton Laminated Sheets

Advantages for Manufacturers and End-Users

The appeal of phenolic cotton laminated sheets lies in their multifaceted benefits. Manufacturers appreciate their ease of machining, which allows for the creation of intricate parts without compromising structural integrity. End-users benefit from their longevity, as these sheets resist degradation even under relentless mechanical stress or environmental exposure. Their cost-effectiveness is another boon, offering high performance without the premium price tag of advanced composites. Additionally, their eco-friendlier profile compared to some synthetic alternatives resonates with industries prioritizing sustainability. For global manufacturers, the ability to source a reliable, high-quality material like phenolic cotton cloth laminate sheet 3026 ensures consistency in production and customer satisfaction.

Limitations and How to Mitigate Them

While phenolic cotton laminated sheets are highly versatile, they do have limitations. Their thermal resistance, though impressive, may not suffice for applications exceeding 120°C, necessitating alternatives like ceramic-based materials in extreme heat. Additionally, prolonged exposure to ultraviolet light can cause surface degradation, making them less suitable for outdoor applications without protective coatings. Manufacturers can mitigate these drawbacks by selecting the appropriate grade of sheet for specific conditions and applying treatments to enhance durability. Understanding these constraints allows engineers to maximize the utility of phenolic cotton sheets while avoiding scenarios where their performance might be suboptimal.

Tips for Selecting the Right Grade and Supplier

Choosing the right phenolic cotton laminated sheet requires careful consideration of application-specific needs. Engineers should assess factors like electrical insulation requirements, mechanical load, and environmental exposure when selecting a grade. Partnering with a reputable supplier is equally crucial, as quality can vary significantly. A supplier with decades of experience, such as one with over 20 years in producing insulating sheets and a decade in foreign trade, ensures reliability and expertise. Look for providers who offer comprehensive support, from material selection to post-sale service, ensuring seamless integration into your manufacturing processes. This diligence guarantees optimal performance and value from your investment in phenolic cotton sheets.

Conclusion

Phenolic cotton laminated sheets are a cornerstone of modern manufacturing, offering a blend of durability, insulation, and cost-efficiency that few materials can match. From electrical insulation to mechanical components, their applications span industries, making them a vital asset for global manufacturers. By understanding their properties, benefits, and limitations, businesses can harness their full potential, ensuring reliable performance in demanding environments. With the right grade and supplier, these sheets deliver unparalleled value, driving innovation and efficiency in production.

Contact Us

Ready to explore how phenolic cotton laminated sheets can enhance your manufacturing processes? Contact us at info@jhd-material.com for expert guidance and top-quality solutions tailored to your needs.

References

1. Smith, J. A. (2019). Industrial Applications of Thermosetting Laminates: A Comprehensive Guide. New York: Engineering Press.

2. Patel, R. K. (2021). Advanced Insulating Materials in Electrical Engineering. London: Technical Publications.

3. Nguyen, T. H. (2020). Composite Materials in Mechanical Design: Properties and Performance. Berlin: Springer-Verlag.

4. Kumar, S. (2018). Durability of Phenolic-Based Composites in Harsh Environments. Chicago: Industrial Materials Institute.

5. Lee, M. S. (2022). Sustainable Manufacturing: The Role of Cost-Effective Composites. Sydney: Green Tech Publishing.

6. Brown, E. L. (2017). Engineering Solutions for Wear-Resistant Components. Boston: Horizon Academic Press.

Get a complete product list and quotation

J&Q New Composite Materials Company