How Does G10 Differ from FR4 Epoxy Sheet?

Composition and Manufacturing Process

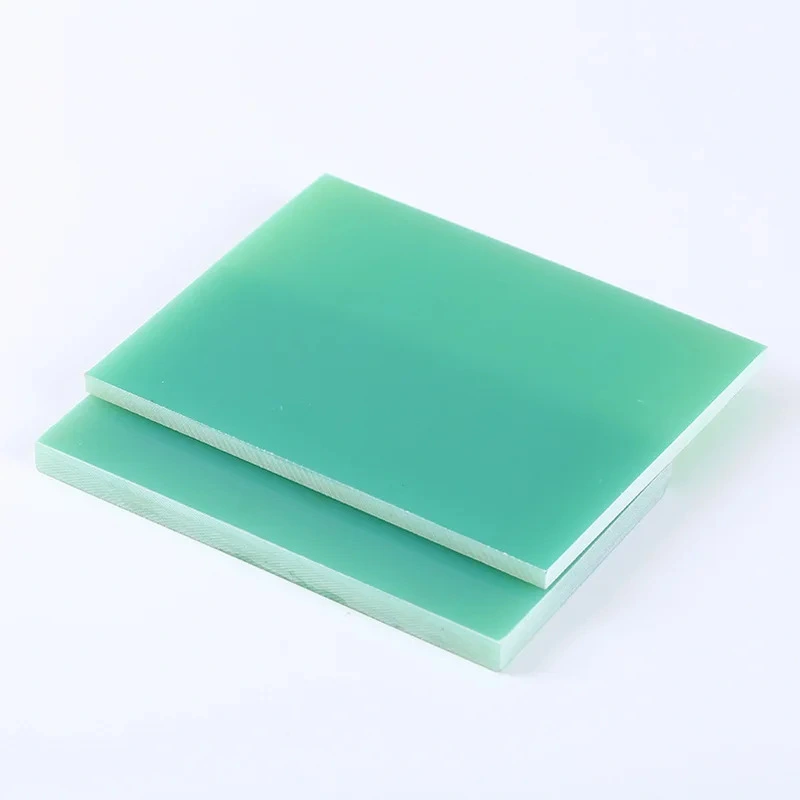

G10 and FR4 are both glass-reinforced epoxy laminates, but their formulation and processing create notable distinctions. G10 is produced with a higher grade of epoxy resin and is cured under stricter conditions, resulting in enhanced structural strength and thermal endurance. This meticulous process yields a laminate with greater dimensional stability and toughness. In contrast, FR4 incorporates flame-retardant additives, which slightly alter its mechanical balance but provide a significant safety advantage. This makes FR4 better suited for environments requiring strict fire resistance.

Thermal Properties and Heat Resistance

When comparing thermal performance, G10 epoxy sheet generally demonstrates superior heat resistance and higher glass transition temperature (Tg) than FR4. This characteristic allows G10 to retain its rigidity, strength, and insulation performance even under elevated operating temperatures. Such stability makes it ideal for aerospace, defense, or high-performance industrial systems exposed to extreme heat or rapid temperature fluctuations. While FR4 performs reliably in most standard electronic environments, its thermal endurance is relatively lower, limiting its application in highly demanding or continuous high-temperature scenarios.

Electrical Insulation Characteristics

Both G10 and FR4 provide dependable electrical insulation, but G10 often offers a distinct advantage in dielectric strength and breakdown voltage capacity. This means G10 can better withstand intense electrical stress without losing insulating performance, making it a preferred option for high-voltage applications, advanced switchgear, or precision electronic instruments. FR4, although slightly lower in these properties, still offers strong insulation suitable for most commercial and industrial uses. Ultimately, G10 is chosen for critical applications requiring maximum electrical reliability under extreme operating conditions.

Mechanical and Chemical Performance Characteristics

Tensile and Flexural Strength

G10 epoxy sheets boast impressive tensile and flexural strength, surpassing many other engineering materials. The combination of high-strength glass fibers and epoxy resin creates a composite that can withstand significant mechanical stress without deformation or failure. This exceptional strength-to-weight ratio makes G10 an attractive option for structural applications in aerospace and automotive industries.

Dimensional Stability and Low Moisture Absorption

One of the standout features of G10 epoxy sheets is their excellent dimensional stability across a wide range of environmental conditions. The material maintains its shape and dimensions even when exposed to temperature fluctuations or high humidity. Additionally, G10 exhibits very low moisture absorption, ensuring consistent performance in damp or underwater environments.

Chemical Resistance and Durability

G10 epoxy sheets demonstrate remarkable resistance to a wide array of chemicals, including acids, alkalis, and organic solvents. This chemical inertness, combined with its inherent durability, makes G10 an ideal material for applications in corrosive environments or where exposure to harsh chemicals is expected. The material's longevity and reliability contribute to reduced maintenance and replacement costs in many industrial applications.

Industrial and Consumer Applications for G10 Sheets

Electronics and Electrical Insulation

In the electronics industry, G10 epoxy sheets are extensively used as substrate materials for printed circuit boards (PCBs), particularly in high-performance and high-reliability applications. The material's excellent dielectric properties, dimensional stability, and resistance to thermal stress make it ideal for multilayer PCBs and other electronic components. G10 is also commonly employed in the manufacture of electrical insulators, bushings, and transformer components, where its high dielectric strength and arc resistance are crucial.

Aerospace and Defense Applications

The aerospace and defense sectors leverage the exceptional properties of G10 epoxy sheets in various applications. The material's high strength-to-weight ratio makes it suitable for structural components in aircraft and spacecraft. G10 is also used in radomes, antenna covers, and other communications equipment due to its low signal attenuation and resistance to environmental factors. In military applications, G10 finds use in ballistic protection systems and as a component in advanced composite armor.

Marine and Underwater Equipment

G10 epoxy sheets excel in marine environments due to their resistance to water absorption and corrosion. The material is commonly used in boat hulls, decking, and other marine structures where strength and durability are paramount. In underwater applications, G10 is employed in the construction of submersible vehicles, sonar equipment housings, and offshore oil and gas industry components. Its ability to maintain structural integrity and electrical properties in submerged conditions makes it an invaluable material for marine engineering.

Conclusion

G10 epoxy sheets represent a pinnacle of engineering materials, offering an unparalleled combination of mechanical strength, electrical insulation, and chemical resistance. Their versatility and reliability have made them indispensable in industries ranging from electronics and aerospace to marine and defense. As technology advances and new challenges emerge, G10 continues to prove its worth as a high-performance composite material capable of meeting the most demanding requirements across diverse applications.

Contact Us

For more information about our G10 epoxy sheets and how they can benefit your specific application, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your needs.