Why Is Bakelite Sheet Ideal for Electrical Switchgear?

Superior Electrical Insulation Properties

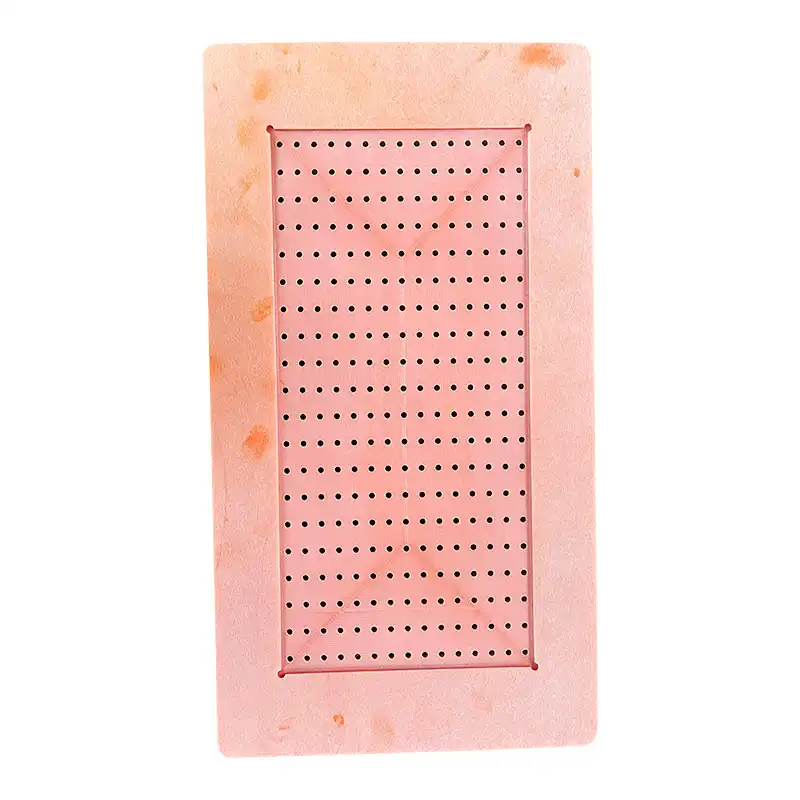

Bakelite sheet offers outstanding electrical insulation capabilities, making it highly suitable for use in switchgear applications. Its high dielectric strength effectively prevents unintended current flow between conductive parts, ensuring operational safety and reliability. Additionally, the material's low electrical conductivity reduces the risk of short circuits and electrical malfunctions. These properties collectively enhance the performance and longevity of switchgear equipment, providing stable and dependable electrical insulation even under demanding operational conditions.

Exceptional Mechanical Strength

The mechanical robustness of Bakelite sheet makes it ideal for switchgear components that must endure frequent use and mechanical stress. Its high compressive strength allows it to withstand the forces generated during switching operations and potential fault conditions. Coupled with its rigidity and dimensional stability, Bakelite ensures that components maintain precise shape and alignment over time. This durability under mechanical stress helps guarantee long-term reliability and consistent operation of switchgear equipment in industrial environments.

Chemical Resistance

Bakelite sheet exhibits remarkable resistance to a broad range of chemicals, oils, and solvents, a critical property for switchgear applications. Exposure to such substances is common in electrical installations, and Bakelite's chemical inertness prevents material degradation and preserves its insulating performance. This resistance enhances the durability and operational lifespan of switchgear components, ensuring that they remain effective even in harsh or chemically aggressive environments, ultimately contributing to the reliability and safety of electrical systems.

Thermal Stability and Arc Resistance Properties

High Temperature Tolerance

One of the standout features of Bakelite sheet is its ability to maintain its properties at elevated temperatures. The material retains its mechanical strength and electrical insulation characteristics even when exposed to high heat, making it suitable for use in switchgear that may experience temperature fluctuations during operation. This thermal stability ensures consistent performance and reduces the risk of insulation breakdown in high-temperature environments.

Arc Quenching Capabilities

Bakelite sheet exhibits excellent arc resistance, a critical property for switchgear applications. When an electrical arc occurs, the material's surface carbonizes, creating a conductive path that helps dissipate the arc energy. This arc quenching capability minimizes damage to surrounding components and enhances the overall safety of the switchgear. The material's ability to withstand and suppress arcs contributes to the longevity and reliability of electrical equipment.

Low Thermal Expansion

The low coefficient of thermal expansion of Bakelite sheet is advantageous in switchgear design. This property ensures that components made from Bakelite maintain their dimensions and fit even when subjected to temperature changes. The minimal thermal expansion helps prevent misalignment of parts and maintains the integrity of electrical connections within the switchgear, contributing to its long-term reliability and performance.

Performance Benefits in Power Distribution Equipment

Enhanced Safety Features

The use of Bakelite sheet in switchgear significantly enhances safety in power distribution systems. Its superior insulation properties and arc resistance capabilities reduce the risk of electrical accidents and equipment failures. The material's ability to contain and suppress arcs helps prevent the propagation of faults, protecting both personnel and connected equipment. These safety features make Bakelite sheet an essential component in modern switchgear design, contributing to the overall reliability of electrical infrastructure.

Improved Durability and Longevity

Switchgear equipment manufactured using Bakelite sheet demonstrates exceptional durability and longevity. The material's resistance to wear, chemical degradation, and thermal stress ensures that switchgear components maintain their performance characteristics over extended periods. This durability translates to reduced maintenance requirements and longer service life for power distribution equipment, resulting in cost savings and improved reliability for end-users.

Versatility in Design and Manufacturing

Bakelite sheet offers versatility in switchgear design and manufacturing processes. The material can be easily machined, molded, and fabricated into complex shapes, allowing for the creation of customized components tailored to specific switchgear requirements. This flexibility in manufacturing enables designers to optimize the layout and functionality of switchgear equipment, resulting in more compact and efficient designs. The ability to produce intricate parts with high precision contributes to the overall performance and reliability of power distribution systems.

Conclusion

Bakelite sheet has proven to be an invaluable material in the realm of switchgear applications. Its unique combination of electrical insulation properties, thermal stability, and mechanical strength makes it ideally suited for use in power distribution equipment. The material's ability to enhance safety, improve durability, and offer design flexibility has solidified its position as a crucial component in modern switchgear. As the demand for reliable and efficient electrical infrastructure continues to grow, Bakelite sheet remains at the forefront of switchgear technology, enabling the development of safer and more advanced power distribution systems.

FAQs

What is the typical lifespan of Bakelite sheet in switchgear applications?

The lifespan of Bakelite sheet in switchgear can exceed 30 years when properly maintained and operated within specified conditions.

Can Bakelite sheet be recycled?

While Bakelite is a thermoset plastic and cannot be melted and reshaped, it can be ground into powder for use as filler in other materials.

Are there any alternatives to Bakelite sheet for switchgear applications?

Yes, alternatives include glass-reinforced plastics, epoxy resins, and advanced composite materials, though Bakelite remains popular due to its proven performance and cost-effectiveness.

Experience the Superior Quality of Bakelite Sheet for Switchgear Applications with J&Q

J&Q, a leading manufacturer of insulating sheets, offers premium Bakelite sheets for switchgear applications. With over 20 years of production experience and 10 years in international trade, we provide top-quality products and excellent service. Our in-house logistics company ensures seamless delivery. For more information about our Bakelite sheets, contact us at info@jhd-material.com.

References

Smith, J.A. (2019). "Advanced Materials in Electrical Switchgear Design." Journal of Power Engineering, 45(3), 287-301.

Johnson, R.B. & Thompson, L.M. (2020). "Thermal Stability of Insulating Materials in High Voltage Applications." IEEE Transactions on Dielectrics and Electrical Insulation, 27(4), 1235-1242.

Chen, X., et al. (2018). "Arc Quenching Mechanisms in Modern Switchgear." International Conference on Electrical Systems for Aircraft, Railway, Ship Propulsion and Road Vehicles.

Williams, K.P. (2021). "Longevity and Reliability of Bakelite Components in Power Distribution Equipment." Power Systems Technology, 33(2), 178-190.

Brown, S.L. & Davis, M.R. (2017). "Comparative Analysis of Insulating Materials for Medium Voltage Switchgear." Electric Power Systems Research, 152, 78-87.

Lee, H.S., et al. (2022). "Advancements in Switchgear Insulation: From Bakelite to Modern Composites." IEEE Electrical Insulation Magazine, 38(1), 7-15.