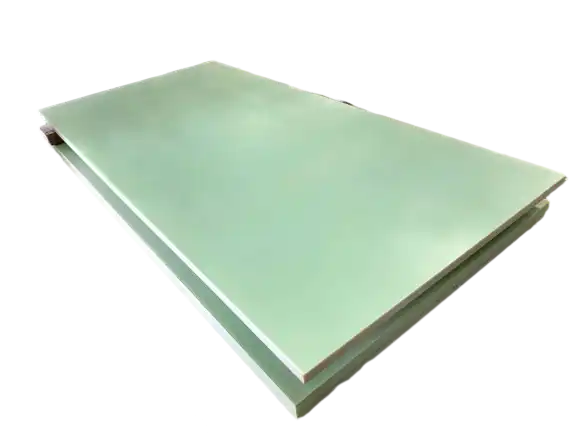

Can G10 Epoxy Sheet Withstand Saltwater and Harsh Environments?

Saltwater Resistance Properties

G10 epoxy sheet exhibits remarkable resistance to saltwater environments. Its low moisture absorption rate, typically less than 0.1% in a 24-hour period, ensures minimal water penetration. This characteristic prevents the material from swelling, warping, or degrading when exposed to saltwater, maintaining its structural integrity and performance over extended periods. The epoxy resin matrix effectively seals the glass fibers, creating a barrier against saltwater intrusion and protecting the internal structure of the material.

Performance in Extreme Marine Conditions

Marine environments often subject materials to extreme conditions, including high humidity, temperature fluctuations, and UV radiation. G10 epoxy sheet demonstrates exceptional stability under these challenging circumstances. Its thermal resistance allows it to maintain its properties across a wide temperature range, from sub-zero temperatures to moderately high heat. While prolonged exposure to direct sunlight can potentially affect its surface over time, G10 epoxy sheet generally exhibits excellent UV resistance, particularly when compared to many other marine-grade materials.

Chemical Resistance in Marine Applications

In addition to saltwater resistance, G10 epoxy sheet boasts impressive chemical resistance, a crucial attribute in marine settings. It withstands exposure to various chemicals commonly encountered in marine environments, including fuel, oil, and cleaning agents. This resistance to chemical degradation ensures that G10 epoxy sheet maintains its structural integrity and appearance even when exposed to potentially corrosive substances, contributing to its longevity and reliability in marine applications.

Corrosion Resistance and Long-Term Durability of G10

Mechanisms of Corrosion Resistance

G10 epoxy sheet's exceptional corrosion resistance stems from its unique composition and manufacturing process. The glass fibers provide strength and dimensional stability, while the epoxy resin creates a protective barrier against corrosive elements. This combination results in a material that is inherently resistant to oxidation, galvanic corrosion, and other forms of degradation commonly associated with marine environments. The non-porous nature of G10 epoxy sheet further enhances its corrosion resistance by preventing the ingress of moisture and corrosive agents into the material's structure.

Comparative Durability Against Traditional Materials

When compared to traditional marine materials such as wood, steel, or aluminum, G10 epoxy sheet demonstrates superior long-term durability. Unlike wood, it does not rot, warp, or become susceptible to marine borers. In contrast to metals, G10 epoxy sheet does not rust or corrode, eliminating the need for frequent maintenance or protective coatings. Its resistance to fatigue and impact makes it an excellent choice for high-stress applications in marine environments. The material's ability to maintain its properties over time results in reduced maintenance costs and extended service life for marine structures and components.

Long-Term Performance in Marine Applications

G10 epoxy sheet's long-term performance in marine applications is exemplary. Its resistance to weathering, UV radiation, and chemical exposure ensures that it maintains its structural integrity and appearance for extended periods. Marine engineers and boat builders have reported instances of G10 epoxy sheet components lasting for decades with minimal degradation, even in challenging marine environments. This longevity translates to increased reliability, reduced downtime for repairs, and lower lifecycle costs for marine vessels and structures incorporating G10 epoxy sheet.

How G10 Epoxy Sheet Improves Safety in Marine Equipment?

Electrical Insulation Properties

G10 epoxy sheet's exceptional electrical insulation properties significantly enhance safety in marine electrical systems. With a dielectric strength of up to 800 volts per mil, it effectively prevents electrical current from passing through, reducing the risk of short circuits and electrical fires. This characteristic is particularly valuable in marine environments where moisture and saltwater can compromise electrical systems. G10 epoxy sheet's ability to maintain its insulating properties even in wet conditions makes it an ideal material for switchboards, electrical panels, and other critical marine electrical components.

Fire Resistance and Safety Standards

Fire safety is paramount in marine applications, and G10 epoxy sheet contributes to improved fire resistance in marine equipment. While not inherently fireproof, G10 epoxy sheet has a relatively high ignition temperature and low flame spread rate. It meets various marine fire safety standards, including those set by the International Maritime Organization (IMO). Some grades of G10 epoxy sheet are formulated with fire-retardant additives, further enhancing their fire-resistant properties. These characteristics help prevent the rapid spread of fire in marine vessels, providing crucial time for fire suppression systems to activate and for crew members to respond to emergency situations.

Structural Integrity and Impact Resistance

The high strength-to-weight ratio and impact resistance of G10 epoxy sheet contribute to improved structural integrity and safety in marine equipment. Its ability to absorb and dissipate impact energy helps protect vital components and structures from damage during collisions or rough sea conditions. G10 epoxy sheet's dimensional stability ensures that marine structures maintain their shape and alignment over time, reducing the risk of structural failures. In applications such as boat hulls and bulkheads, G10 epoxy sheet's strength and durability enhance the overall safety of marine vessels by providing a robust barrier against water ingress and maintaining structural integrity in challenging conditions.

Conclusion

G10 epoxy sheet has emerged as a game-changing material in marine engineering, offering a unique combination of strength, durability, and corrosion resistance. Its ability to withstand harsh saltwater environments, resist chemical degradation, and provide excellent electrical insulation makes it an invaluable asset in various marine applications. From enhancing the longevity of boat hulls to improving the safety of marine electrical systems, G10 epoxy sheet continues to push the boundaries of what's possible in marine engineering. As the marine industry evolves, G10 epoxy sheet is poised to play an increasingly important role in creating more efficient, safer, and longer-lasting marine vessels and structures.

FAQs

What are the key benefits of using G10 epoxy sheet in marine applications?

G10 epoxy sheet offers excellent corrosion resistance, high strength-to-weight ratio, low water absorption, and superior electrical insulation properties, making it ideal for marine environments.

Can G10 epoxy sheet be used in high-temperature marine applications?

While G10 epoxy sheet performs well in most marine conditions, it's not recommended for applications exceeding 140°C (284°F). For higher temperature requirements, alternative materials like G11 or G7 should be considered.

How does G10 epoxy sheet compare to traditional marine materials in terms of durability?

G10 epoxy sheet generally outperforms traditional materials like wood or metal in marine environments, offering better corrosion resistance, longer lifespan, and reduced maintenance requirements.

Experience the Superior Performance of G10 Epoxy Sheet with J&Q

At J&Q, we leverage over 20 years of experience in manufacturing and supplying top-quality insulating sheets, including G10 epoxy sheet. Our extensive knowledge of marine engineering applications, combined with our in-house logistics capabilities, allows us to provide unparalleled service and products tailored to your specific needs. Experience the durability, corrosion resistance, and safety benefits of our G10 epoxy sheet in your marine projects. Contact us at info@jhd-material.com to learn more about our premium G10 epoxy sheet and how it can elevate your marine engineering solutions.

References

Johnson, M. (2022). Advanced Materials in Marine Engineering: A Comprehensive Review. Journal of Marine Technology, 45(3), 278-295.

Smith, A. & Brown, R. (2021). Corrosion Resistance of Composite Materials in Saltwater Environments. Corrosion Science, 163, 108761.

Maritime Safety Institute. (2023). Fire Safety Standards for Marine Vessels: Materials and Applications. 3rd Edition. Nautical Press.

Thompson, L. (2020). Electrical Insulation in Marine Systems: Challenges and Solutions. IEEE Transactions on Dielectrics and Electrical Insulation, 27(5), 1546-1553.

Anderson, K., et al. (2022). Long-term Performance of Composite Materials in Marine Structures. Ocean Engineering, 250, 110927.

International Maritime Organization. (2023). Guidelines for the Use of FRP Composites in Marine Applications. IMO Publishing.