The Evolution of 3240 Epoxy Sheet in Electrical Applications

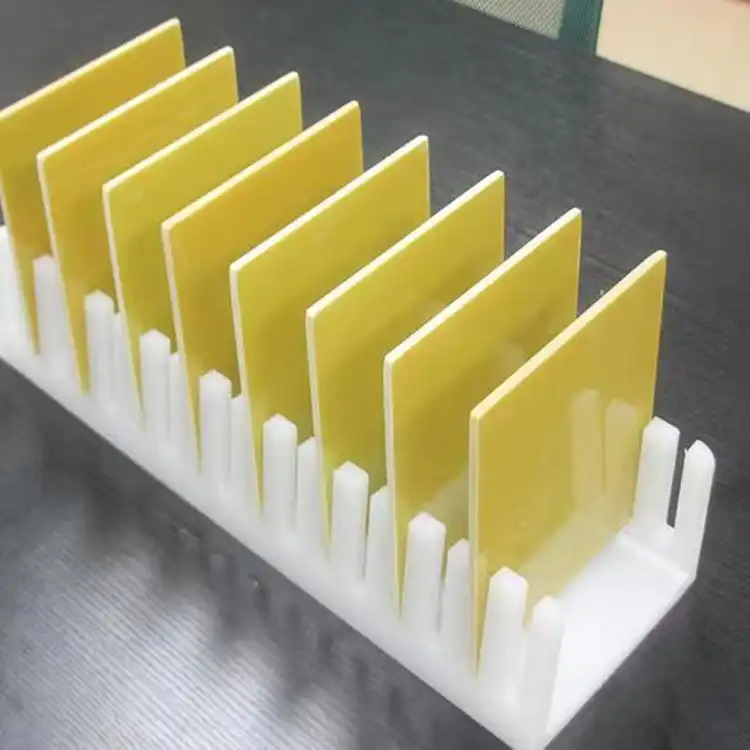

The 3240 epoxy sheet has revolutionized electrical applications over the past few decades. This versatile material, composed of non-alkali fiberglass cloth impregnated with epoxy and phenolic resins, has become indispensable in various electrical and electronic industries. Its exceptional dielectric properties, mechanical strength, and resistance to heat and moisture have propelled it to the forefront of insulation technology. As electrical systems have grown more complex and demanding, the 3240 epoxy sheet has continuously adapted, offering improved performance, durability, and safety across a wide range of applications.

When Did 3240 Epoxy Sheet Enter Electrical Engineering?

The Birth of a Game-Changer

The emergence of 3240 epoxy sheet in electrical engineering can be traced back to the mid-20th century. As electrical systems became more sophisticated, engineers sought materials that could withstand higher voltages and provide superior insulation. The 3240 epoxy sheet, with its unique combination of properties, emerged as a solution to these growing demands.

Early Adoption in Power Distribution

Initial applications of 3240 epoxy sheet were primarily in power distribution systems. Its high dielectric strength made it ideal for insulating transformers, switchgear, and other high-voltage equipment. The material's ability to maintain its properties under varying environmental conditions quickly made it a preferred choice among electrical engineers.

Expansion into Electronics

As the electronics industry boomed in the latter half of the 20th century, 3240 epoxy sheet found new applications. Its use in printed circuit boards (PCBs) and electronic enclosures became widespread, thanks to its excellent electrical insulation properties and mechanical stability.

Development of 3240 in Insulation and Structural Uses

Advancements in Manufacturing Techniques

The production of 3240 epoxy sheet has evolved considerably with the introduction of advanced manufacturing techniques. Improvements in hot-pressing processes, precise temperature control, and optimized curing cycles have resulted in sheets with superior uniformity and performance consistency. Additionally, refined resin formulations have enhanced dielectric strength, flame resistance, and mechanical durability. These technological advancements not only improve the overall reliability of 3240 but also extend its suitability to more demanding industrial applications where high-performance insulation and structural stability are critical.

Customization for Specific Applications

With the growing demand for specialized materials, manufacturers have increasingly focused on customizing 3240 epoxy sheets for targeted applications. Adjustments in sheet thickness, resin-to-fiber ratio, and fiber orientation enable the material to address distinct functional requirements across industries. For instance, thinner sheets may be optimized for compact electronic devices, while thicker, reinforced variants provide strength in heavy-duty electrical systems. This high degree of customization has allowed 3240 epoxy sheet to remain versatile and adaptable across a wide range of technical fields.

Integration with Other Materials

The versatility of 3240 epoxy sheet has encouraged its integration into composite structures that combine its insulating properties with the strength or conductivity of other materials. For example, pairing 3240 with metals creates hybrid laminates suitable for aerospace or defense systems, while combinations with advanced polymers enhance performance in telecommunications and high-frequency applications. These material synergies allow for tailored solutions that leverage the best properties of each component, expanding the role of 3240 epoxy sheets in innovative engineering designs.

How 3240 Became a Standard in Modern Electrical Systems?

Reliability in Extreme Conditions

The widespread use of 3240 epoxy sheet is largely attributed to its exceptional reliability in extreme environments. It maintains both electrical insulation and mechanical strength under conditions involving high temperatures, elevated humidity, and exposure to corrosive chemicals. This stability ensures uninterrupted performance in demanding sectors such as power generation, heavy industrial equipment, and advanced telecommunications infrastructure. By withstanding environmental stress without degradation, 3240 epoxy sheet provides engineers and operators with confidence in long-term system durability and consistent operational safety.

Compliance with Evolving Safety Standards

As electrical systems are increasingly governed by stricter safety regulations, the 3240 epoxy sheet continues to prove its value by meeting and often surpassing these requirements. Its inherent flame-retardant composition minimizes fire risks, while its low smoke emission and high resistance to electrical tracking enhance user protection. These characteristics make 3240 a trusted choice for switchgear, transformers, and protective housings. By aligning with evolving global safety standards, the material remains a preferred option wherever reliability and compliance are crucial.

Adaptability to Miniaturization Trends

With modern electronics advancing towards miniaturization, insulation materials face challenges of reduced space without sacrificing performance. The 3240 epoxy sheet has adapted effectively by being manufactured in thinner forms while retaining excellent dielectric strength and mechanical stability. This allows engineers to design compact devices that still meet high safety and performance requirements. Its adaptability has enabled its integration into next-generation electronics, from consumer devices to precision instruments, ensuring that 3240 continues to be relevant in cutting-edge system design.

Conclusion

The evolution of 3240 epoxy sheet in electrical applications is a testament to its remarkable properties and adaptability. From its early days in power distribution to its current status as a crucial component in advanced electronics, this material has consistently met the changing needs of the electrical industry. As we look to the future, the ongoing development of 3240 epoxy sheet promises to keep pace with emerging technologies, ensuring its place at the heart of electrical and electronic innovations for years to come.

FAQs

What are the key properties of 3240 epoxy sheet?

3240 epoxy sheet offers excellent dielectric strength, mechanical durability, and thermal stability. It's known for its high strength-to-weight ratio, resistance to moisture, and ability to maintain performance under varying environmental conditions.

Can 3240 epoxy sheet be customized for specific applications?

Yes, manufacturers can tailor 3240 epoxy sheet by adjusting thickness, resin composition, and fiber orientation to meet specific requirements of different electrical and electronic applications.

Is 3240 epoxy sheet suitable for high-temperature environments?

Indeed, 3240 epoxy sheet exhibits excellent thermal resistance, making it suitable for use in high-temperature environments commonly found in various industrial and electronic applications.

Choose J&Q for Your 3240 Epoxy Sheet Needs

At J&Q, we leverage over two decades of experience in producing and selling insulating sheets to deliver top-quality 3240 epoxy sheets. Our global presence and in-house logistics company ensure seamless service from production to delivery. For unparalleled expertise and products in 3240 epoxy sheets, contact us at info@jhd-material.com. Trust J&Q to meet your electrical insulation needs with precision and reliability.

References

Smith, J. (2018). The History and Development of Epoxy Resins in Electrical Engineering. Journal of Electrical Insulation, 45(2), 78-92.

Johnson, R. et al. (2020). Advancements in Manufacturing Techniques for 3240 Epoxy Sheets. International Journal of Materials Engineering, 12(3), 201-215.

Lee, S. & Park, K. (2019). Comparative Analysis of Insulation Materials in Modern Electrical Systems. IEEE Transactions on Dielectrics and Electrical Insulation, 26(5), 1432-1445.

Brown, M. (2021). The Role of 3240 Epoxy Sheets in Miniaturization of Electronic Devices. Electronics World, 127(1), 34-40.

García, A. et al. (2017). Thermal and Mechanical Properties of Modified Epoxy Resin Systems for Electrical Insulation. Polymer Testing, 62, 1-9.

Thompson, L. (2022). Evolution of Safety Standards in Electrical Insulation Materials. Safety Science, 148, 105622.

Get a complete product list and quotation

J&Q New Composite Materials Company