Fundamentals of CE Phenolic Sheets and Electrical Strength

Composition and Manufacturing Process

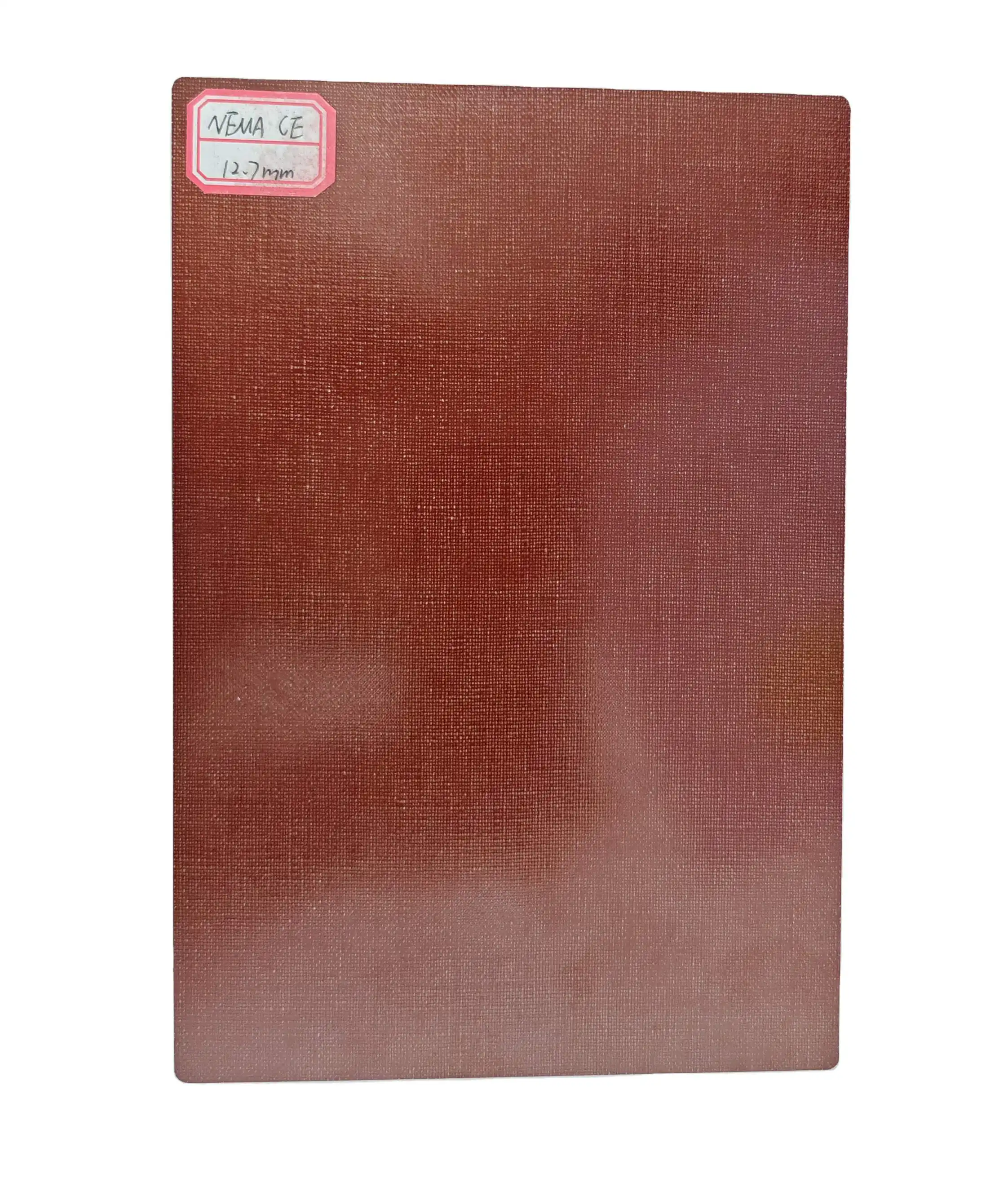

CE phenolic sheets are crafted from a sophisticated blend of phenol-formaldehyde resins and reinforcing materials. The manufacturing process involves carefully layering these components and subjecting them to high pressure and temperature. This results in a dense, cross-linked structure that contributes significantly to the sheet's electrical insulating properties. The meticulous control of raw materials and processing conditions ensures consistent electrical strength across the entire sheet.

Molecular Structure and Insulation Properties

The molecular structure of CE phenolic sheets plays a pivotal role in their electrical strength. The phenolic resin matrix forms a tightly bonded network that impedes electron movement. This intricate arrangement of molecules creates numerous barriers that electrons must overcome, effectively increasing the voltage required for electrical breakdown. The incorporation of reinforcing materials further enhances this property by introducing additional interfaces that disrupt electron flow.

Factors Influencing Electrical Strength

Several factors can influence the electrical strength of CE phenolic sheets. Thickness is a primary consideration, with thicker sheets generally offering higher electrical strength. Environmental conditions, such as temperature and humidity, can also affect performance. Additionally, the presence of impurities or voids in the material can create weak points that may compromise electrical strength. Manufacturers employ rigorous quality control measures to minimize these variables and ensure consistent electrical properties.

Testing and Measurement of Electrical Strength in CE Phenolic Sheets

Standard Testing Methods

The electrical strength of CE phenolic sheets is typically evaluated using standardized testing procedures. One common method is the short-time dielectric breakdown test, where a gradually increasing voltage is applied across the sheet until breakdown occurs. This test provides valuable data on the maximum voltage a sheet can withstand before failure. Other tests, such as the step-by-step test, involve applying voltage in increments to assess long-term dielectric performance.

Equipment and Procedures

Specialized equipment is essential for accurately measuring the electrical strength of CE phenolic sheets. High-voltage test sets, capable of generating voltages up to several hundred kilovolts, are commonly employed. These systems often feature precision voltage control and safety interlocks to ensure reliable and safe testing. Test specimens are carefully prepared and conditioned to eliminate surface contamination that could skew results. The testing environment is controlled to maintain consistent temperature and humidity levels.

Interpretation of Results

Interpreting electrical strength test results requires a nuanced understanding of material properties and testing conditions. While a single breakdown value is often reported, it's crucial to consider statistical variations across multiple samples. Engineers analyze these results in the context of safety factors and application requirements to determine the suitability of CE phenolic sheets for specific uses. Trend analysis of test data over time can also provide insights into material consistency and manufacturing process stability.

Applications and Advantages of CE Phenolic Sheets in Electrical Insulation

High-Voltage Applications

The exceptional electrical strength of CE phenolic sheets makes them indispensable in high-voltage applications. They are frequently used in transformer construction, serving as barriers between windings and as spacers in oil-filled units. In switchgear assemblies, these sheets provide critical insulation between conductive components, preventing arcing and ensuring safe operation. The ability of CE phenolic sheets to maintain their insulating properties under extreme conditions contributes to the reliability of power distribution systems.

Electronics and Circuit Board Manufacturing

In the realm of electronics, CE phenolic sheets find extensive use as substrate materials for printed circuit boards (PCBs). Their high electrical strength ensures effective isolation between conductive traces, even in densely packed circuits. This property is particularly valuable in high-frequency applications where signal integrity is paramount. The dimensional stability of CE phenolic sheets under varying environmental conditions further enhances their suitability for precision electronic components.

Comparative Advantages Over Other Insulating Materials

CE phenolic sheets offer several advantages over alternative insulating materials. Compared to many plastics, they exhibit superior heat resistance and dimensional stability, making them suitable for applications involving elevated temperatures. Their electrical strength often surpasses that of natural materials like mica or press board, allowing for more compact designs in high-voltage equipment. Additionally, CE phenolic sheets demonstrate excellent machinability, facilitating the production of complex shapes and precision components for specialized insulation needs.

Conclusion

The electrical strength of CE phenolic sheets is a cornerstone of their functionality in electrical and electronic applications. Through a combination of advanced manufacturing techniques and inherent material properties, these sheets provide reliable insulation in demanding environments. As technology continues to evolve, the role of CE phenolic sheets in ensuring safe and efficient electrical systems remains paramount. Their versatility, coupled with consistent performance, positions CE phenolic sheets as a critical material in the ongoing development of electrical infrastructure and electronic devices.

Contact Us

For more information about our CE phenolic sheets and their electrical properties, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect insulation solution for your specific needs.