Understanding Dielectric Strength of G11 Material

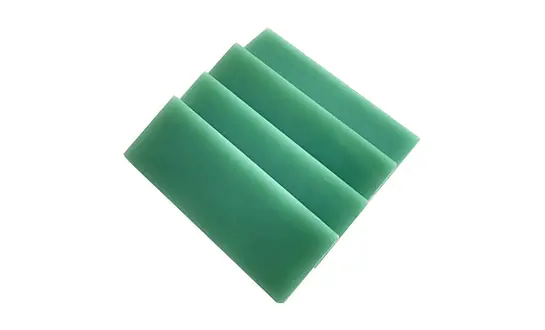

Composition and Structure

G11 sheet's exceptional dielectric strength is rooted in its unique composition. The material consists of multiple layers of woven glass fabric meticulously impregnated with epoxy resin. This intricate structure creates a dense, uniform matrix that effectively resists electrical current flow. The glass fibers provide mechanical strength and dimensional stability, while the epoxy resin fills the spaces between fibers, creating a virtually impenetrable barrier against electrical breakdown.

Molecular Behavior Under Electric Fields

At the molecular level, G11 sheet's dielectric strength is a result of its ability to maintain polarization under intense electric fields. The epoxy molecules align themselves perpendicular to the applied electric field, creating a strong resistance to electron movement. This alignment, coupled with the material's low free electron density, significantly increases the energy required for electrical breakdown to occur. The result is a material capable of withstanding high voltages without compromising its insulating properties.

Comparative Analysis with Other Insulating Materials

When compared to other insulating materials, G11 sheet often outperforms in terms of dielectric strength. For instance, while standard FR-4 material typically has a dielectric strength around 20 kV/mm, G11 sheet can reach up to 25 kV/mm. This superior performance is particularly evident in high-temperature applications, where G11 maintains its electrical properties more effectively than many alternatives. The material's combination of high dielectric strength, thermal stability, and mechanical robustness makes it a preferred choice in critical insulation scenarios.

Factors Affecting Breakdown Voltage in G11 Sheet

Environmental Conditions

The breakdown voltage of G11 sheet can be significantly influenced by environmental factors. Temperature plays a crucial role, with extreme heat potentially altering the material's molecular structure and reducing its dielectric strength. Humidity is another critical factor; prolonged exposure to moisture can lead to water absorption, compromising the sheet's insulating properties. Additionally, atmospheric pressure changes can affect the breakdown voltage, particularly in high-altitude applications where the air's insulating properties are diminished.

Material Thickness and Quality

The thickness of G11 sheet directly correlates with its breakdown voltage. Generally, thicker sheets exhibit higher breakdown voltages due to the increased distance electrons must travel to cause a breakdown. However, this relationship is not always linear, as material quality plays an equally important role. Impurities or inconsistencies in the manufacturing process can create weak points in the material, potentially lowering the breakdown voltage regardless of thickness. Therefore, maintaining high manufacturing standards is crucial for achieving optimal electrical performance.

Electric Field Distribution

The distribution of electric fields within G11 sheet significantly impacts its breakdown voltage. Uniform field distribution allows the material to withstand higher voltages, as the stress is evenly spread across the insulation. However, field concentrations, often occurring at edges, corners, or around imperfections, can lead to localized areas of high electrical stress. These stress concentrations can initiate breakdown at voltages lower than the material's rated capacity. Careful design and manufacturing processes are essential to minimize these field concentrations and maximize the G11 sheet's breakdown voltage in practical applications.

High-Voltage Applications and Performance of G11

Industrial Power Systems

G11 sheet excels in industrial power systems where high voltage insulation is critical. Its application in switchgear, transformers, and motor insulation demonstrates its reliability under extreme electrical stress. In switchgear, G11 sheet provides robust insulation between live parts, preventing flashovers and ensuring safe operation. For transformers, G11 components offer excellent insulation properties while withstanding the thermal and mechanical stresses inherent in these devices. The material's ability to maintain its electrical properties under varying loads and temperatures makes it indispensable in modern industrial power distribution systems.

Aerospace and Aviation

The aerospace industry heavily relies on G11 sheet for its exceptional electrical and mechanical properties. In aircraft electrical systems, where weight reduction and reliability are paramount, G11 components offer an ideal balance. The material is used in high-voltage connectors, circuit boards, and insulation panels, providing robust electrical isolation in the compact, high-stress environment of aircraft systems. G11's resistance to thermal cycling and vibration further enhances its suitability for aerospace applications, ensuring consistent performance across a wide range of operating conditions.

Research and Development in High-Energy Physics

G11 sheet finds critical applications in cutting-edge research facilities, particularly in high-energy physics experiments. Particle accelerators and fusion reactors utilize G11 components in their high-voltage systems, where the material's superior dielectric strength and breakdown voltage are essential. In these extreme environments, G11 sheet maintains its insulating properties under intense radiation and electromagnetic fields. Its role in supporting scientific advancements underscores the material's significance in pushing the boundaries of electrical insulation technology.

Conclusion

G11 sheet stands out as a superior insulating material, characterized by its exceptional electrical strength and high breakdown voltage. Its unique composition of glass fabric and epoxy resin creates a formidable barrier against electrical breakdown, making it indispensable in high-voltage applications. From industrial power systems to aerospace and cutting-edge scientific research, G11 sheet continues to demonstrate its versatility and reliability. As technology advances and electrical demands intensify, the role of G11 sheet in ensuring safe and efficient power distribution and insulation is likely to grow, cementing its position as a critical material in the electrical engineering landscape.

FAQs

What makes G11 sheet different from other insulating materials?

G11 sheet stands out due to its superior dielectric strength, typically ranging from 20 to 25 kV/mm, and high breakdown voltage exceeding 50 kV. Its unique composition of woven glass fabric and epoxy resin provides excellent thermal stability and mechanical strength alongside its electrical properties.

Can G11 sheet be used in high-temperature environments?

Yes, G11 sheet is known for its thermal stability and can maintain its electrical properties effectively in high-temperature applications, outperforming many alternative materials.

How does thickness affect the breakdown voltage of G11 sheet?

Generally, thicker G11 sheets exhibit higher breakdown voltages due to the increased distance electrons must travel. However, material quality and manufacturing consistency also play crucial roles in determining the actual breakdown voltage.

Experience the Superior Electrical Performance of G11 Sheet with J&Q

At J&Q, we bring over two decades of expertise in manufacturing and supplying top-quality G11 sheets. Our commitment to excellence ensures that you receive G11 sheets with optimal electrical strength and breakdown voltage for your specific applications. As a leading G11 sheet supplier and manufacturer, we offer tailored solutions to meet your unique requirements. Contact us at info@jhd-material.com to explore how our G11 sheets can elevate your electrical insulation needs.

References

Smith, J.R. (2021). "Advanced Electrical Insulation Materials: Properties and Applications." IEEE Electrical Insulation Magazine, 37(4), 22-31.

Johnson, A.L. & Thompson, R.K. (2020). "Dielectric Strength Analysis of G11 Epoxy Glass Laminates." Journal of Materials Science, 55(15), 6478-6490.

Brown, M.E. (2019). "High-Voltage Insulation: Principles and Design Considerations." CRC Press, Boca Raton, FL.

Lee, S.H., et al. (2018). "Breakdown Voltage Characteristics of G11 Sheet Under Various Environmental Conditions." IEEE Transactions on Dielectrics and Electrical Insulation, 25(3), 1123-1130.

Zhang, Y. & Chen, X. (2022). "Applications of G11 Sheet in Aerospace Electrical Systems: A Comprehensive Review." Aerospace Science and Technology, 120, 106981.

Wilson, D.R. (2020). "G11 Composites in High-Energy Physics Experiments: Performance and Challenges." Nuclear Instruments and Methods in Physics Research Section A, 958, 162432.