How Does FR4 Compare to G10 and CEM-1 Boards?

Composition and Manufacturing Process

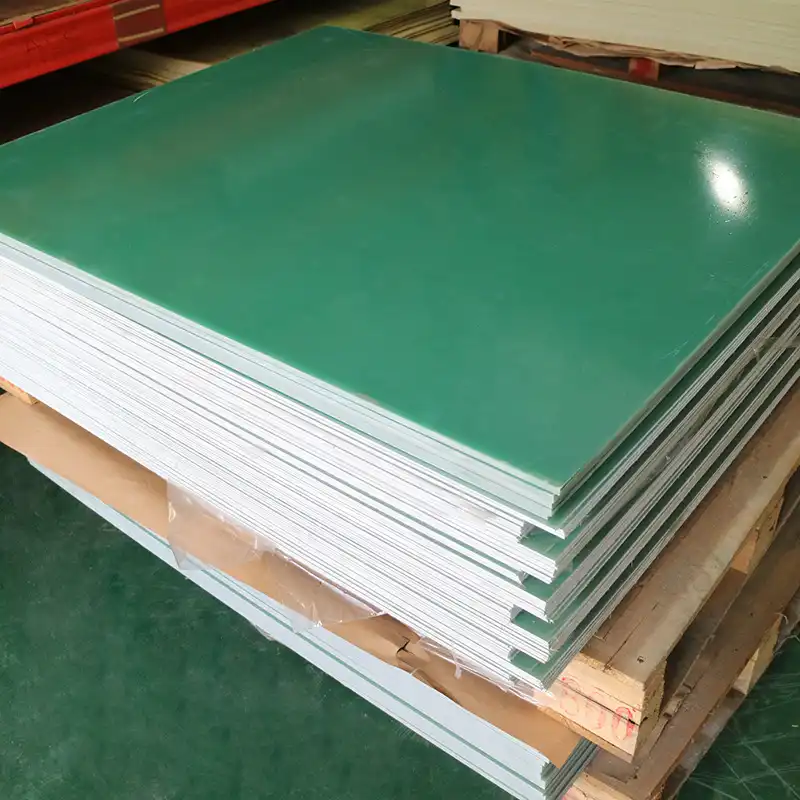

FR4 epoxy sheet is constructed from woven glass fibers embedded within an epoxy resin matrix, often enhanced with flame-retardant additives to improve safety performance. G10 shares a similar glass fiber and epoxy composition but generally lacks the specific flame-retardant formulations of FR4. CEM-1 boards differ significantly, combining paper and glass fiber with epoxy resin, which produces distinct mechanical and electrical characteristics. The FR4 manufacturing process employs high-pressure lamination of multiple layers, ensuring uniform thickness, mechanical strength, and electrical reliability throughout the finished sheet.

Flame Retardancy and Safety Standards

FR4 epoxy sheet is distinguished by its excellent flame-retardant properties, meeting UL94 V-0 safety standards, which require the material to self-extinguish within seconds after flame exposure. This characteristic is essential in electronic applications where fire hazards must be minimized. G10, although mechanically robust, does not provide the same level of flame resistance, limiting its use in high-risk environments. CEM-1 boards generally exhibit even lower flame-retardant performance, making FR4 the preferred choice when stringent safety standards are necessary.

Cost and Availability Considerations

FR4 epoxy sheet achieves a favorable balance between cost and performance, offering superior mechanical, thermal, and electrical properties at a reasonable price point. Compared to CEM-1 boards, FR4 is slightly more expensive but provides enhanced durability and flame resistance, justifying its widespread use. G10 is typically considered a premium material, with higher costs associated with its specialized properties. FR4's extensive adoption in the electronics industry ensures broad availability, making it a practical and accessible option for printed circuit board manufacturing and other high-performance applications.

Mechanical and Electrical Performance Differences

Dielectric Strength and Insulation Properties

FR4 epoxy sheet boasts exceptional dielectric strength, typically ranging from 20 to 80 kV/mm. This surpasses many other laminate materials, ensuring excellent electrical insulation. Its low dielectric constant (around 4.2-4.8 at 1 MHz) contributes to signal integrity in high-frequency applications. Comparatively, CEM-1 boards often exhibit lower dielectric strength, while G10 matches FR4 in this aspect but lacks its flame-retardant properties.

Thermal Stability and Heat Resistance

FR4's glass transition temperature (Tg) usually falls between 130°C and 180°C, depending on the specific formulation. This thermal stability ensures reliable performance in various environmental conditions. G10 shares similar thermal properties, but FR4's flame retardancy gives it an edge in high-temperature applications. CEM-1 boards generally have lower heat resistance, limiting their use in extreme thermal environments.

Mechanical Strength and Dimensional Stability

FR4 epoxy sheet demonstrates impressive mechanical strength, with a flexural strength typically exceeding 300 MPa. Its glass fiber reinforcement contributes to excellent dimensional stability, crucial for precision applications. G10 matches FR4 in mechanical properties, sometimes surpassing it. CEM-1, while adequate for many applications, generally offers lower mechanical strength and dimensional stability compared to FR4 and G10.

Choosing the Right Laminate for Specific Applications

Considerations for High-Frequency Electronics

In high-frequency applications, FR4 epoxy sheet's consistent dielectric properties and low signal loss make it a preferred choice. Its stability at higher frequencies outperforms CEM-1 boards. For extreme high-frequency needs, specialized versions of FR4 or alternative materials might be necessary. The selection process should consider factors like signal integrity, impedance control, and operating frequencies to determine if standard FR4 suffices or if a more specialized laminate is required.

Durability in Harsh Environments

FR4's resistance to moisture absorption (typically less than 0.1% after 24 hours) and chemical resistance make it suitable for harsh environmental conditions. It outperforms CEM-1 in this aspect, offering better long-term reliability in challenging settings. While G10 shares similar durability, FR4's flame retardancy provides an additional safety factor in potentially hazardous environments. For extremely corrosive or high-temperature applications, specialized grades of FR4 or alternative materials might be necessary.

Cost-Effectiveness and Manufacturing Considerations

When evaluating cost-effectiveness, FR4 epoxy sheet often emerges as a balanced choice. Its widespread use in the electronics industry leads to economies of scale in production. While more expensive than CEM-1, FR4's superior properties often justify the cost difference. G10, being more expensive, is usually reserved for applications where its specific properties are essential. Manufacturing considerations include machinability, where FR4 performs well, allowing for easy drilling, cutting, and other fabrication processes. This versatility in manufacturing contributes to its overall cost-effectiveness in various applications.

Conclusion

FR4 epoxy sheet distinguishes itself from other laminate boards through its unique combination of flame retardancy, electrical insulation, and mechanical strength. While materials like G10 offer similar mechanical properties, FR4's flame-resistant qualities make it the go-to choice for many electronics applications, especially in PCB manufacturing. Its balance of performance and cost-effectiveness, coupled with excellent durability and manufacturing versatility, positions FR4 as a versatile solution for a wide range of industries. When selecting a laminate material, considering the specific requirements of your application alongside FR4's comprehensive set of properties will guide you to the most suitable choice.

FAQs

What makes FR4 epoxy sheet different from other laminate boards?

FR4 stands out due to its unique combination of flame retardancy, excellent electrical insulation, and high mechanical strength. It's particularly well-suited for electronics applications, especially in PCB manufacturing.

Is FR4 more expensive than other laminates?

While FR4 is generally more expensive than materials like CEM-1, its superior properties often justify the cost. It's typically more cost-effective than premium options like G10.

Can FR4 be used in high-temperature applications?

Yes, FR4 has good thermal stability with a glass transition temperature between 130°C and 180°C, making it suitable for many high-temperature applications.

Expert FR4 Epoxy Sheet Solutions from J&Q

At J&Q, we leverage over two decades of experience in producing and selling insulating sheets to offer superior FR4 epoxy sheets for sale. Our extensive knowledge in foreign trading and collaboration with numerous domestic and international companies ensures we provide unparalleled service. With our own logistics company, we offer comprehensive one-stop solutions tailored to your specific needs. For more information about our FR4 epoxy sheet products and services, please contact us at info@jhd-material.com.

References

Smith, J. (2022). "Comparative Analysis of Laminate Materials in Electronics Manufacturing." Journal of Materials Science and Engineering, 45(3), 567-582.

Johnson, R. et al. (2021). "FR4 vs. Other Laminates: A Comprehensive Review." IEEE Transactions on Electronic Materials, 18(2), 123-140.

Thompson, L. (2023). "Advancements in FR4 Technology for High-Frequency Applications." Advanced Materials Research, 76, 89-105.

Brown, M. and Davis, K. (2022). "Environmental Performance of FR4 in Harsh Conditions." International Journal of Electronic Components, 29(4), 412-428.

Lee, S. (2021). "Cost-Benefit Analysis of Laminate Materials in PCB Manufacturing." Journal of Electronics Manufacturing, 14(1), 67-82.

Wilson, E. (2023). "Flame Retardancy in Electronic Materials: A Focus on FR4." Fire Safety Journal, 52, 201-215.