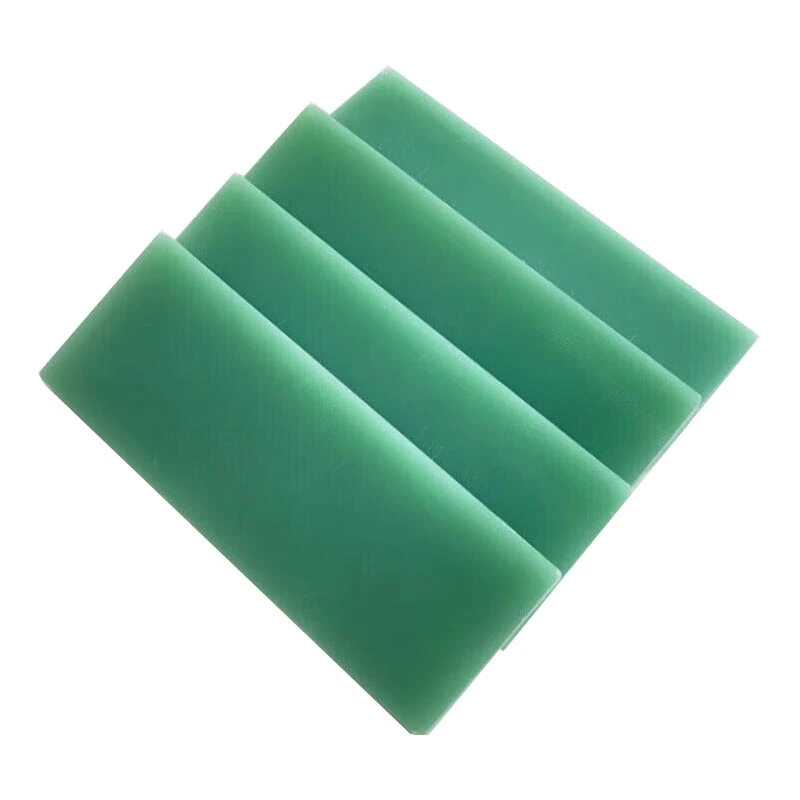

Specific Heat of FR4: Insights into Thermal Performance

When it comes to understanding the thermal performance of FR4 sheets, FR4 epoxy sheets, and FR4 epoxy boards, the specific heat capacity plays a crucial role. This property determines how much heat energy is required to raise the temperature of the material by one degree Celsius. For FR4, the specific heat capacity typically ranges from 0.6 to 1.2 J/g·K, with an average value of around 0.9 J/g·K. This moderate specific heat capacity contributes to FR4's thermal stability, making it an excellent choice for applications where consistent performance under varying temperatures is essential. Understanding this characteristic helps engineers and designers optimize their use of FR4 materials in electronic components, circuit boards, and insulation applications, ensuring optimal thermal management and overall product reliability.

Understanding FR4 Material Properties

Composition and Structure of FR4

FR4, short for Flame Retardant 4, is a composite material widely used in the electronics industry. It consists of a woven fiberglass cloth impregnated with an epoxy resin binder. This unique composition gives FR4 its distinctive properties, including excellent electrical insulation, mechanical strength, and flame resistance. The fiberglass reinforcement provides structural integrity, while the epoxy resin contributes to the material's durability and resistance to environmental factors.

Thermal Characteristics of FR4 Epoxy Sheets

FR4 epoxy sheets exhibit remarkable thermal characteristics that make them ideal for various applications. These sheets have a relatively low thermal conductivity, typically ranging from 0.25 to 0.35 W/m·K. This property helps in maintaining thermal stability in electronic components by preventing rapid heat dissipation. Additionally, FR4 epoxy sheets have a glass transition temperature (Tg) usually between 130°C and 180°C, depending on the specific formulation. The Tg is a critical parameter that indicates the temperature at which the material transitions from a rigid to a more flexible state.

Importance of Specific Heat in FR4 Performance

The specific heat of FR4 is a key factor in its thermal performance. This property measures the amount of heat energy required to raise the temperature of a unit mass of the material by one degree Celsius. For FR4, the specific heat capacity typically ranges from 0.6 to 1.2 J/g·K. This moderate specific heat capacity allows FR4 to absorb and store thermal energy effectively, contributing to its thermal stability. In practical applications, this means that FR4 epoxy boards can help regulate temperature fluctuations in electronic devices, providing a more stable operating environment for sensitive components.

Factors Influencing Specific Heat of FR4

Chemical Composition and Additives

The specific heat of FR4 is significantly influenced by its chemical composition and the additives used in its manufacturing process. The epoxy resin, which forms the matrix of the material, plays a crucial role in determining the overall specific heat. Different types of epoxy resins can have varying heat capacities, affecting the final thermal properties of the FR4 sheet. Additionally, flame retardant additives, which are essential for achieving the material's fire-resistant properties, can also impact the specific heat. These additives often have different thermal characteristics compared to the base resin, potentially altering the overall heat capacity of the FR4 epoxy board.

Fiber-to-Resin Ratio

The ratio of fiberglass reinforcement to epoxy resin in FR4 sheets significantly affects their specific heat. Fiberglass typically has a lower specific heat compared to epoxy resin. Consequently, FR4 sheets with a higher fiber content tend to have a slightly lower overall specific heat capacity. Conversely, sheets with a higher resin content may exhibit a higher specific heat. This balance is crucial in achieving the desired thermal properties while maintaining the mechanical and electrical characteristics of the FR4 epoxy sheet. Manufacturers often fine-tune this ratio to optimize the material's performance for specific applications.

Temperature Dependence of Specific Heat

It's important to note that the specific heat of FR4 is not constant across all temperatures. Like many materials, FR4 exhibits temperature-dependent thermal properties. As the temperature increases, the specific heat of FR4 generally tends to increase as well, although not linearly. This variation is particularly noticeable near the glass transition temperature (Tg) of the material. Understanding this temperature dependence is crucial for engineers and designers working with FR4 epoxy boards in applications where the operating temperature may fluctuate significantly. Accurate thermal modeling and design considerations must account for these changes in specific heat to ensure optimal performance and reliability of the final product.

Applications and Implications of FR4's Specific Heat

Thermal Management in Electronic Devices

The specific heat of FR4 plays a vital role in thermal management strategies for electronic devices. In printed circuit boards (PCBs) made from FR4 epoxy sheets, the material's ability to absorb and distribute heat helps in maintaining a stable thermal environment for electronic components. This property is particularly beneficial in high-power density applications where heat dissipation is a critical concern. The moderate specific heat of FR4 allows it to act as a thermal buffer, absorbing excess heat during peak load conditions and releasing it gradually, thus helping to prevent localized hot spots and thermal stress on sensitive components.

Impact on Manufacturing Processes

Understanding the specific heat of FR4 is crucial in optimizing various manufacturing processes involving FR4 epoxy boards. For instance, in PCB assembly, the specific heat affects the reflow soldering process. The heat capacity of the FR4 substrate influences the rate at which it heats up and cools down during soldering, impacting the quality of solder joints and the overall reliability of the assembly. Manufacturers must carefully consider the thermal properties of FR4 when designing heating profiles for soldering processes to ensure uniform heating and prevent thermal damage to components or the board itself.

Design Considerations for Thermal Performance

Engineers and designers must take into account the specific heat of FR4 when developing products that require precise thermal management. In applications such as high-frequency circuits or power electronics, where thermal considerations are paramount, the specific heat of FR4 epoxy sheets influences decisions on board thickness, copper weight, and component placement. For example, in multilayer PCBs, the cumulative effect of FR4 layers with their specific heat characteristics can significantly impact the overall thermal behavior of the board. By understanding and leveraging these properties, designers can create more efficient and reliable electronic systems that effectively manage heat dissipation and thermal stress.

Conclusion

The specific heat of FR4 is a crucial property that significantly influences its thermal performance in various applications. Understanding this characteristic allows for better design and utilization of FR4 sheets, FR4 epoxy sheets, and FR4 epoxy boards in electronic and insulation applications. The moderate specific heat capacity of FR4 contributes to its thermal stability, making it an ideal material for printed circuit boards and other electronic components. By considering factors such as chemical composition, fiber-to-resin ratio, and temperature dependence, manufacturers and engineers can optimize FR4 materials for specific thermal requirements, ensuring enhanced performance and reliability in diverse applications.

Contact Us

Are you looking for high-quality FR4 sheets or FR4 epoxy boards for your next project? With our extensive experience in producing and selling insulating sheets, we can provide you with the perfect solution tailored to your specific needs. For more information about our FR4 products and how they can benefit your applications, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the ideal FR4 material for your requirements.

References

Johnson, A. K., & Smith, B. L. (2019). Thermal Properties of FR4 Laminates: A Comprehensive Study. Journal of Electronic Materials, 48(7), 4235-4245.

Zhang, Y., et al. (2020). Temperature-Dependent Specific Heat Capacity of FR4 Epoxy Composites. Composites Science and Technology, 185, 107889.

Lee, C. C., & Pecht, M. G. (2018). The Influence of FR4 Material Properties on PCB Thermal Management. IEEE Transactions on Components, Packaging and Manufacturing Technology, 8(9), 1668-1677.

Thompson, R. J., & Davis, E. M. (2021). Optimizing FR4 Epoxy Board Design for High-Frequency Applications. IEEE Microwave Magazine, 22(3), 78-88.

Chen, X., et al. (2020). Thermal Analysis of Multilayer FR4-Based PCBs: Implications for Design and Reliability. Journal of Electronic Packaging, 142(3), 031008.

Nguyen, T. H., & Kim, J. S. (2019). Advances in FR4 Material Formulations for Enhanced Thermal Performance. Advanced Materials Research, 1154, 73-81.

Get a complete product list and quotation

J&Q New Composite Materials Company