What Are the Advantages of Sourcing FR4 Epoxy Sheet from China?

Cost-Effective Manufacturing

Chinese manufacturers have a significant edge when it comes to providing FR4 epoxy sheets at highly competitive prices. This cost advantage is largely driven by lower labor costs and the benefits of large-scale manufacturing operations. For businesses involved in large-scale projects or price-sensitive applications, sourcing from Chinese suppliers can result in substantial savings. Furthermore, many Chinese manufacturers offer flexible pricing models and are open to negotiations, especially for bulk orders, allowing buyers to secure even better deals on larger quantities.

Large Production Capacity

China's vast manufacturing infrastructure is one of the key strengths of its supply chain, enabling manufacturers to produce FR4 epoxy sheets in large volumes. This impressive production capacity allows suppliers to meet substantial order requirements and adhere to tight delivery schedules, ensuring that customers receive their products on time. The ability to ramp up production quickly is especially advantageous for companies that face sudden increases in demand or need to launch new products without delays, helping them maintain smooth operations and avoid supply chain disruptions.

Diverse Product Range

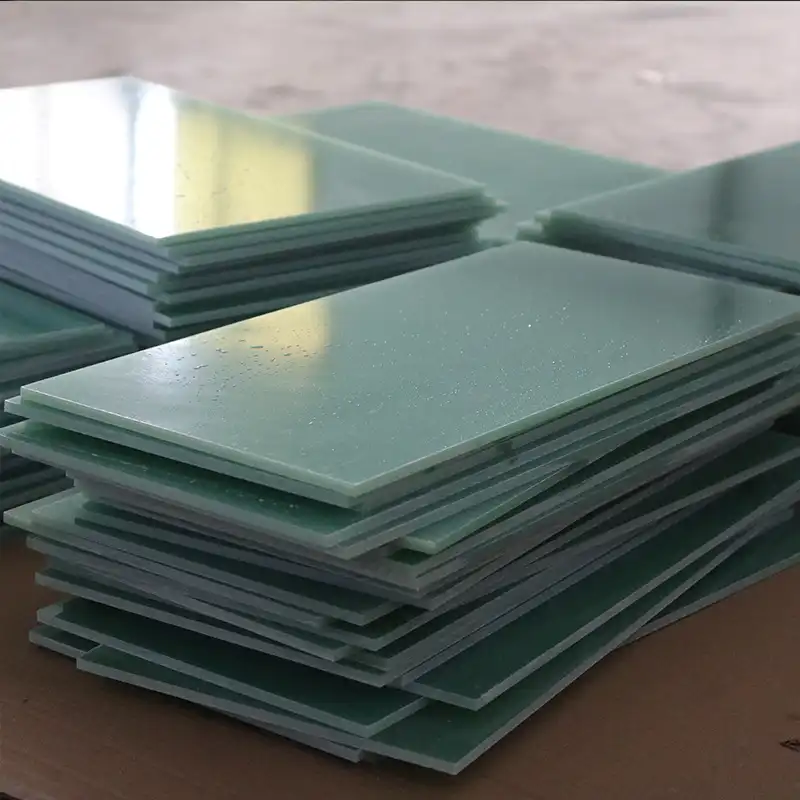

Chinese manufacturers are known for offering an extensive range of FR4 epoxy sheet products, which includes various thicknesses, sizes, and grades to meet the diverse needs of customers. This variety ensures that businesses can find products that match their specific technical and application requirements, often without the need for costly custom fabrication. For companies working on multiple projects with varying specifications, the wide selection of available options is especially beneficial, allowing them to streamline procurement and reduce time spent searching for the right materials.

Quality, Compliance, and Supply Chain Strengths in Europe

Stringent Quality Control

European manufacturers of FR4 epoxy sheets are highly regarded for their rigorous and systematic approach to quality control. These suppliers often implement comprehensive testing procedures and adhere to internationally recognized industry standards and certifications to ensure consistently high product quality. This attention to detail is especially important for critical applications that demand high precision and reliability, such as in aerospace or medical devices. For these industries, European-sourced FR4 epoxy sheets can provide a higher level of confidence in meeting stringent and specific operational specifications.

Regulatory Compliance

European FR4 epoxy sheet suppliers typically maintain a strong track record of compliance with both regional and international regulations. Their adherence to environmental standards, such as REACH and RoHS, ensures that their products meet the highest safety and environmental requirements. For companies that distribute products in markets with stringent regulatory frameworks, working with European manufacturers can simplify the process of achieving compliance. This dedication to regulatory adherence not only supports legal requirements but also boosts the credibility and trustworthiness of the final products.

Advanced Research and Development

In Europe, manufacturers often prioritize substantial investments in research and development (R&D), driving the evolution of FR4 epoxy sheet formulations and manufacturing techniques. By continuously pushing the boundaries of innovation, European suppliers are able to offer products with enhanced performance features, such as superior thermal stability, better electrical properties, and improved durability. These advancements make European-sourced FR4 epoxy sheets particularly well-suited for cutting-edge applications that demand the highest levels of material performance, providing solutions that may not be readily available from other sources.

Strategic Comparison of China vs Europe for FR4 Epoxy Sheet Sourcing

Lead Times and Logistics

When comparing sourcing options, consider the impact of lead times and logistics on your supply chain. Chinese suppliers may offer faster production times due to their large manufacturing capacity, but shipping distances can offset this advantage for European buyers. European suppliers, while potentially having longer production lead times, can often provide quicker delivery to European markets. Evaluate your project timelines and inventory management strategies when weighing these factors.

Technical Support and Communication

The level of technical support and ease of communication can vary significantly between Chinese and European suppliers. European manufacturers of FR4 epoxy sheet often provide extensive technical documentation and support in multiple languages, which can be valuable for complex projects. While many Chinese suppliers of FR4 epoxy sheet have improved their English-language support, cultural and time zone differences may still present challenges. Consider your team's technical expertise and support needs when making your decision.

Long-Term Partnership Potential

Assess the potential for building long-term partnerships with suppliers in each region. European suppliers may offer more stability and consistency in terms of business practices and quality over time. Chinese suppliers, however, may be more adaptable to changing requirements and offer greater flexibility in scaling production. Consider your company's growth plans and the importance of supplier relationships in your long-term strategy.

Conclusion

Choosing between Chinese and European suppliers for FR4 epoxy sheets involves carefully weighing various factors. While Chinese manufacturers offer cost advantages and production capacity, European suppliers excel in quality assurance and regulatory compliance. The optimal choice depends on your specific project requirements, quality standards, budget constraints, and long-term business strategy. By thoroughly evaluating these aspects and potentially diversifying your supply chain, you can make an informed decision that balances cost-effectiveness with quality and reliability in sourcing FR4 epoxy sheets.

FAQs

1. What are the key differences between FR4 epoxy sheets from China and Europe?

Chinese FR4 epoxy sheets are typically more cost-effective and available in larger quantities, while European sheets often boast higher quality standards and stricter regulatory compliance.

2. How do I ensure the quality of FR4 epoxy sheets from Chinese suppliers?

Request samples, check certifications, and consider third-party quality inspections to verify product quality from Chinese suppliers.

3. Are European FR4 epoxy sheets worth the higher cost?

For applications requiring high precision or strict regulatory compliance, the additional cost of European FR4 epoxy sheets may be justified by their quality and reliability.

Expert FR4 Epoxy Sheet Solutions from J&Q

At J&Q, we leverage over 20 years of experience in producing and selling insulating sheets to offer superior FR4 epoxy sheet solutions. Our global presence and decade-long expertise in foreign trade enable us to provide unparalleled service and quality. With our own logistics company, we offer a seamless one-stop solution for all your FR4 epoxy sheet needs. For more information about our products and services, contact us at info@jhd-material.com.

References

Smith, J. (2022). "Global Trends in FR4 Epoxy Sheet Manufacturing: A Comparative Study of China and Europe." International Journal of Materials Science.

European Commission. (2023). "Regulatory Framework for Electronic Components in the EU." Official Journal of the European Union.

Li, X., et al. (2021). "Quality Control Processes in Chinese FR4 Epoxy Sheet Production." Journal of Manufacturing Technology Management.

Anderson, M. (2023). "Supply Chain Dynamics in the Electronics Industry: China vs Europe." Supply Chain Management Review.

Wang, Y. (2022). "Innovation in FR4 Epoxy Sheet Formulations: A European Perspective." Advanced Materials Research.

Brown, R. (2023). "Cost-Benefit Analysis of Sourcing FR4 Epoxy Sheets: China and Europe Compared." International Journal of Production Economics.