How Does Phenolic Resin Contribute to EV Safety and Efficiency?

Enhanced Electrical Insulation for Critical Components

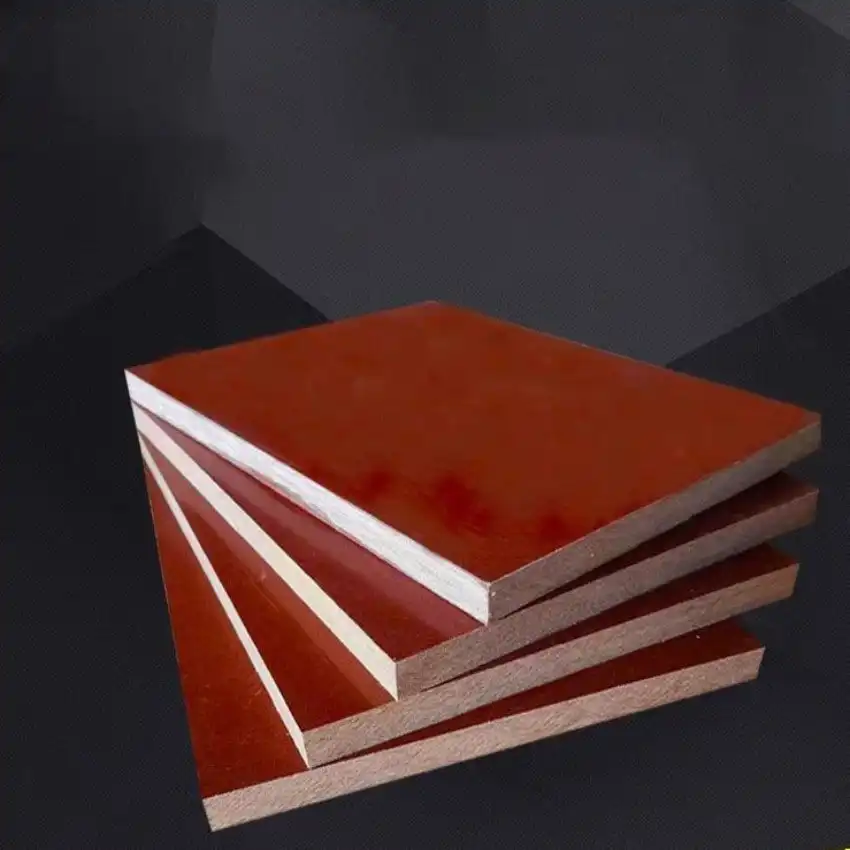

Phenolic resin sheets provide outstanding electrical insulation for critical electric vehicle components. Their high dielectric strength and very low electrical conductivity effectively protect sensitive electronics from electrical interference and potential short circuits. This superior insulation capability plays a vital role in enhancing the overall safety and reliability of electric vehicles, helping to prevent electrical failures that could degrade vehicle performance or create safety risks. As a result, phenolic resin sheets are a trusted material choice for safeguarding essential EV systems.

Thermal Management in High-Temperature Environments

The excellent heat resistance of phenolic resin sheets makes them invaluable for thermal management within electric vehicles. These materials can endure high operating temperatures without suffering degradation, preserving the function and safety of components exposed to heat generated by batteries, electric motors, and power electronics. By facilitating efficient heat dissipation and maintaining thermal stability, phenolic resin sheets help prevent overheating and related failures, thereby supporting consistent vehicle performance and extending the lifespan of critical EV systems under demanding thermal conditions.

Mechanical Strength for Structural Integrity

Phenolic resin sheets exhibit exceptional mechanical strength, contributing significantly to the structural integrity of various electric vehicle components. Their ability to withstand mechanical stresses, vibrations, and impacts makes them ideal for use in motor housings, battery enclosures, and other support structures. This robustness not only enhances durability but also improves safety by protecting vital parts from damage during normal operation or harsh driving conditions. Consequently, phenolic resin sheets play an important role in ensuring the long-term reliability and resilience of electric vehicles.

Heat Resistance and Electrical Isolation in Battery Modules

Thermal Insulation for Battery Cells

In EV battery modules, phenolic resin sheets serve as effective thermal insulators, helping to maintain optimal operating temperatures for battery cells. By minimizing heat transfer between cells and the surrounding environment, these materials contribute to improved battery performance, extended lifespan, and enhanced safety. The thermal insulation properties of phenolic resin sheets are particularly valuable in preventing thermal runaway events, which can pose significant safety risks in electric vehicles.

Electrical Separation Between Battery Components

Phenolic resin sheets play a crucial role in providing electrical separation between various components within battery modules. Their excellent dielectric properties ensure that individual battery cells remain electrically isolated from one another and from the surrounding structure. This isolation is essential for preventing short circuits and maintaining the overall integrity of the battery system, contributing to the safe and efficient operation of electric vehicles.

Chemical Resistance in Battery Environments

The chemical resistance of phenolic resin sheets makes them well-suited for use in battery modules, where exposure to electrolytes and other potentially corrosive substances is common. These materials maintain their structural and electrical properties even when in contact with battery chemicals, ensuring long-term reliability and safety. The chemical stability of phenolic resin sheets helps prevent degradation that could compromise the performance or safety of EV battery systems over time.

Lightweight Insulation Materials for Sustainable EV Design

Weight Reduction for Improved Vehicle Efficiency

Phenolic resin sheets offer a lightweight alternative to traditional insulation materials, contributing to overall weight reduction in electric vehicles. By incorporating these lightweight materials into various components, automakers can improve vehicle efficiency and extend driving range without compromising on safety or performance. The use of phenolic resin sheets aligns with the industry's focus on sustainable design practices and the ongoing efforts to maximize the energy efficiency of electric vehicles.

Recyclability and Environmental Considerations

As the automotive industry places increasing emphasis on sustainability, the recyclability of phenolic resin sheets becomes a significant advantage. These materials can be recycled and repurposed at the end of their lifecycle, reducing waste and environmental impact. The ability to recycle phenolic resin components aligns with circular economy principles and supports automakers' efforts to develop more environmentally friendly electric vehicles.

Versatility in EV Component Design

The versatility of phenolic resin sheets allows for their implementation in a wide range of EV components beyond battery modules. From interior panels to underhood applications, these materials can be tailored to meet specific design requirements while maintaining their essential properties. This versatility enables automotive engineers to optimize component design for weight, strength, and insulation performance, contributing to the overall efficiency and sustainability of electric vehicles.

Conclusion

Phenolic resin sheets have emerged as indispensable materials in the development of advanced electric vehicle components. Their unique combination of electrical insulation, heat resistance, and mechanical strength addresses critical challenges in EV design and manufacturing. As the automotive industry continues to innovate and improve electric vehicle technology, the role of phenolic resin sheets in enhancing safety, efficiency, and sustainability will likely expand, driving further advancements in EV performance and reliability.

Contact Us

To learn more about our high-quality phenolic resin sheets for electric vehicle applications, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the optimal insulation solutions for your EV components.