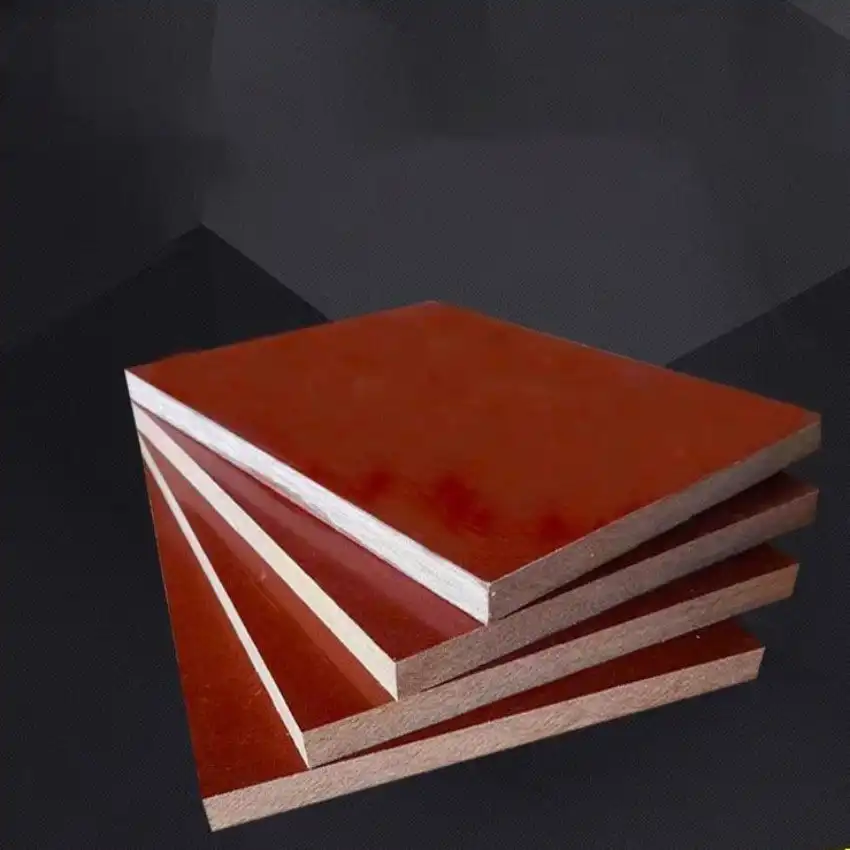

Phenolic Cotton Sheet Temperature and Wear Resistance

Phenolic cotton sheet excels in handling elevated temperatures and abrasive conditions, thanks to its composite makeup of cotton fabric infused with phenolic resin. This material typically endures continuous exposure up to 120°C, with brief excursions to 150°C possible without immediate failure. Exceeding these limits may cause resin degradation, leading to brittleness or loss of adhesion between layers. In terms of wear, its dense structure resists friction superbly, making it suitable for gears, bushings, and insulators under mechanical duress. The cotton fibers provide tenacity, while the resin offers a slick, durable surface that minimizes erosion over time. Industries value this for its balance of thermal fortitude and abrasion defiance, ensuring components last longer in harsh setups. Proper selection and maintenance amplify these traits, preventing premature wear or thermal breakdown.

How Does Temperature Affect Phenolic Cotton Sheet Performance?

Temperature plays a pivotal role in how phenolic cotton sheet behaves, influencing everything from structural integrity to electrical properties. As heat rises, the material's resin matrix responds in ways that can either enhance or impair its utility. Drawing from our two decades of crafting insulating sheets, we've observed how subtle thermal shifts impact real-world applications, guiding clients toward optimal choices through our global trading insights.

Thermal Expansion and Contraction Dynamics

When subjected to heat, the sheet undergoes minimal expansion due to its laminated design, which curbs warping in assemblies. Cotton fibers absorb some stress, preventing cracks during cooling cycles. This stability proves crucial in fluctuating environments, like motor housings, where consistent dimensions maintain tight tolerances. Our collaborations with international partners have refined formulations that bolster this resilience, ensuring sheets adapt without faltering.

Impact on Electrical Insulation

Rising temperatures can alter dielectric strength, yet phenolic cotton sheet retains robust insulating capabilities up to its threshold. The resin's cross-linked nature resists breakdown, safeguarding against arcs in high-voltage scenarios. Moisture resistance aids here, as heat often pairs with humidity in industrial zones. Leveraging our one-stop logistics service, we deliver variants tuned for such demands, helping users avoid costly disruptions.

Strategies to Mitigate Heat-Related Issues

Incorporating ventilation in designs dissipates excess warmth, extending service life. Pairing with compatible adhesives enhances bonding under thermal loads. Monitoring exposure durations prevents cumulative damage. Our extensive foreign trade experience equips us to recommend these approaches, backed by perfect services honed over years of partnerships.

Wear Resistance Properties Under High-Stress Conditions

Under relentless stress, phenolic cotton sheet demonstrates remarkable endurance against abrasion, a trait stemming from its interwoven fabric and resilient binder. This makes it a stalwart in environments where friction reigns, reducing the need for frequent replacements. With over 20 years in insulating sheet production, we at J&Q appreciate how these properties translate to efficiency gains for our global clientele.

Surface Hardness and Friction Tolerance

Phenolic cotton sheet's exterior boasts impressive hardness, fending off gouges from particulate matter or sliding contacts. Cotton's inherent pliancy cushions impacts, while the phenolic infusion creates a low-friction veneer. This combination shines in bearings or guides, where constant motion erodes softer alternatives swiftly. Our decade-plus in foreign trading has allowed us to source materials that elevate this toughness, meeting diverse industrial rigors.

Behavior in Dynamic Load Scenarios

In vibrating or oscillating setups, the material absorbs shocks without splintering, thanks to its layered construction. Fatigue resistance emerges as a key asset, with fibers distributing loads evenly to avert localized wear. Applications in conveyor systems highlight this, enduring repetitive strains admirably. Through ongoing collaborations with trading companies, we've optimized sheets for such challenges, ensuring they thrive amid persistent duress.

Enhancing Durability Through Application Techniques

Applying lubricants forms a protective barrier, curtailing direct abrasion. Aligning grain directions in machining bolsters strength against shear forces. Routine assessments catch wear patterns early. Our own logistics arm facilitates swift supply of tailored options, empowering users to sustain peak performance in demanding operations.

Thermal Stability and Long-Term Durability

Thermal stability intertwines with durability, defining how phenolic cotton sheet withstands prolonged exposure without succumbing to degradation. This synergy ensures it remains viable over extended periods, a boon for cost-sensitive projects. Our proven track record in selling insulating sheets worldwide underscores the value of these attributes, supported by seamless one-stop services.

Chemical Integrity Over Time

Sustained heat tests the resin's bonds, yet high-quality phenolic cotton sheet preserves its composition, resisting oxidation or volatilization. This longevity stems from precise curing during manufacture, locking in stability. In chemical processing equipment, it defies corrosive atmospheres paired with warmth. Insights from our multi-year trading alliances inform enhancements, yielding sheets that endure without compromise.

Interaction with Environmental Factors

Humidity and pollutants can exacerbate thermal wear, but the material's sealed structure repels intrusions, maintaining robustness. UV exposure poses less threat due to inherent opacity. Outdoor electrical enclosures benefit from this, holding firm through seasons. Our global outreach has gathered data on these interactions, refining products for varied climates.

Predictive Maintenance for Extended Lifespan

Implementing thermal imaging spots hotspots preemptively, averting failures. Cycling tests during selection mimic real conditions, forecasting endurance. Upgrading to reinforced grades amplifies resilience. With our integrated logistics, we provide ongoing support, ensuring your investments in phenolic cotton sheet yield lasting returns.

Conclusion

Phenolic cotton sheet merges thermal resilience with wear defiance, capably managing up to 120°C ongoing and brief spikes to 150°C, while its fabric-resin blend combats abrasion in strenuous roles. This positions it as a dependable choice for insulation and mechanical components across industries. Smart implementation, like ventilation and lubrication, heightens its longevity, cutting maintenance needs. At J&Q, our 20+ years of expertise in production, coupled with a decade in foreign trading and our logistics prowess, deliver unmatched one-stop solutions. Embrace these benefits for your projects and witness enhanced reliability.

Contact Us

Curious about integrating phenolic cotton sheet into your operations? Drop us a line for personalized guidance, quotes, or samples. Contact info@jhd-material.com today - we're eager to assist!

References

"Phenolic Resins Technology Handbook" by NPCS Board of Consultants & Engineers.

"Wear of Materials" edited by Peter J. Blau.

ASTM D229 Standard Test Methods for Rigid Sheet and Plate Materials.

"Polymer Composites" by Klaus Friedrich and Alois K. Schlarb.

ISO 4587 Adhesives - Determination of tensile lap-shear strength.

"Handbook of Thermoset Plastics" by Hanna Dodiuk and Sidney H. Goodman.

Get a complete product list and quotation

J&Q New Composite Materials Company