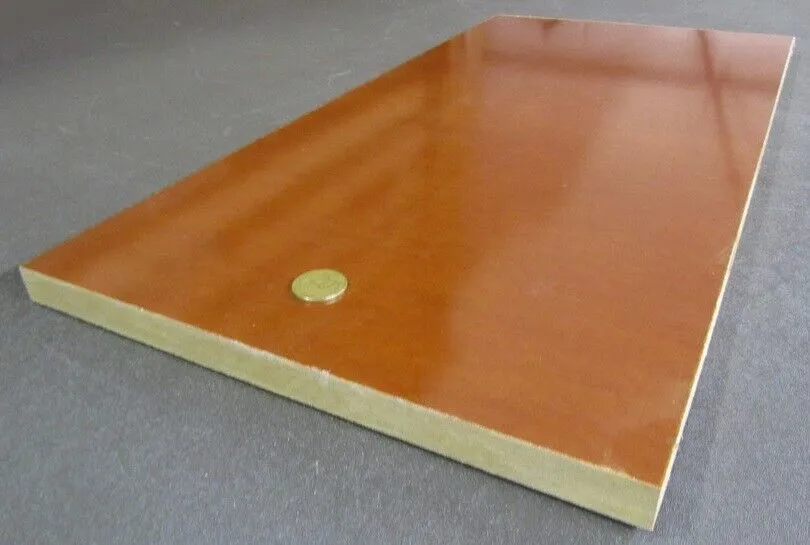

What Mechanical and Electrical Properties Define Phenolic Cotton Sheet Quality

Flexural Strength and Impact Resistance

The flexural strength of phenolic cotton sheets is a paramount quality metric, indicating the material's ability to withstand bending forces without fracturing. High-quality sheets typically exhibit flexural strength values ranging from 100 to 150 MPa, depending on the specific grade and manufacturing process. This property is particularly crucial for applications where the material may experience repeated stress or vibration.

Impact resistance, measured through methods such as the Izod impact test, provides insight into the material's toughness and ability to absorb energy without fracturing. Superior phenolic cotton sheets often demonstrate impact strengths of 5 to 10 kJ/m², making them suitable for applications requiring durability under sudden loads or impacts.

Dielectric Strength and Volume Resistivity

Dielectric strength, measured in kV/mm, is a critical electrical property that determines the maximum electric field a phenolic cotton sheet can withstand before electrical breakdown occurs. High-quality sheets typically exhibit dielectric strengths exceeding 20 kV/mm, ensuring reliable insulation in electrical applications.

Volume resistivity, expressed in ohm-cm, quantifies the material's ability to resist electrical current flow through its bulk. Premium phenolic cotton sheets boast volume resistivity values of 10^10 to 10^14 ohm-cm, providing excellent electrical insulation properties crucial for many industrial and electrical components.

Tensile Strength and Compressive Strength

Tensile strength, measured in MPa, indicates the maximum stress the material can withstand before failing under tension. Quality phenolic cotton sheets often exhibit tensile strengths ranging from 60 to 100 MPa, ensuring structural integrity in various applications.

Compressive strength, also measured in MPa, represents the material's ability to withstand loads that reduce its size. High-grade phenolic cotton sheets typically demonstrate compressive strengths of 150 to 300 MPa, making them suitable for applications involving significant compressive forces.

Dimensional Stability, Density, and Surface Finish Evaluation

Thermal Expansion and Moisture Absorption

Coefficient of thermal expansion (CTE) is a crucial metric for assessing dimensional stability across temperature fluctuations. Superior phenolic cotton sheets exhibit low CTE values, typically ranging from 20 to 30 × 10^-6 /°C, ensuring minimal dimensional changes in varying thermal conditions.

Moisture absorption, measured as a percentage of weight gain, affects the material's dimensional stability and electrical properties. High-quality phenolic cotton sheets demonstrate low moisture absorption rates, generally below 2% after 24 hours of immersion, maintaining their performance in humid environments.

Density and Specific Gravity

Density, measured in g/cm³, is an essential quality metric influencing the material's weight and mechanical properties. Premium phenolic cotton sheets typically have densities ranging from 1.3 to 1.4 g/cm³, balancing strength with weight considerations.

Specific gravity, a dimensionless ratio of the material's density to that of water, provides a quick comparison between different materials. Quality phenolic cotton sheets often have specific gravity values between 1.3 and 1.4, offering a favorable strength-to-weight ratio for various applications.

Surface Roughness and Flatness

Surface roughness, measured in micrometers (µm), affects the material's friction properties and suitability for certain applications. High-quality phenolic cotton sheets typically exhibit surface roughness values below 1.6 µm, ensuring smooth operation in mechanical systems and reducing wear.

Flatness, often expressed as a deviation from a perfectly flat surface, is crucial for applications requiring precise alignment or sealing. Premium sheets maintain flatness tolerances within ±0.2 mm per meter, ensuring consistent performance across the material's surface.

Standardized Testing Methods for Industrial-Grade Phenolic Sheets

ASTM Standards for Mechanical Properties

ASTM D790 is the standard test method for determining flexural properties of unreinforced and reinforced plastics, including phenolic cotton sheets. This test provides crucial data on the material's bending strength and stiffness, essential for applications involving load-bearing components.

ASTM D638 standardizes the tensile testing procedure for plastics, yielding valuable information on the material's ultimate tensile strength, elongation at break, and modulus of elasticity. These properties are vital for assessing the phenolic cotton sheet's performance under tension in various industrial applications.

IEC Standards for Electrical Properties

IEC 60243-1 establishes the standard test method for determining the electric strength of insulating materials at power frequencies. This test is crucial for evaluating the dielectric strength of phenolic cotton sheets, ensuring their suitability for electrical insulation applications.

IEC 60093 provides standardized methods for measuring volume and surface resistivity of solid electrical insulating materials. These tests are essential for assessing the phenolic cotton sheet's ability to resist electrical current flow, both through its bulk and along its surface.

ISO Standards for Environmental and Chemical Resistance

ISO 62 standardizes the method for determining water absorption in plastics, including phenolic cotton sheets. This test is crucial for assessing the material's dimensional stability and potential changes in electrical properties when exposed to moisture.

ISO 175 establishes procedures for evaluating the resistance of plastics to chemical substances. For phenolic cotton sheets, this test helps determine their suitability for applications involving exposure to various chemicals, oils, or solvents commonly encountered in industrial environments.

Conclusion

Understanding the quality metrics of phenolic cotton sheets is essential for buyers seeking optimal performance in their industrial and electrical applications. By considering mechanical properties like flexural strength and impact resistance, electrical characteristics such as dielectric strength and volume resistivity, and physical attributes including dimensional stability and surface finish, buyers can make informed decisions. Adhering to standardized testing methods ensures consistent evaluation across different manufacturers and grades. This comprehensive approach to quality assessment guarantees the selection of phenolic cotton sheets that meet specific project requirements, ultimately leading to improved product reliability and longevity.

FAQs

1. What is the typical temperature range for phenolic cotton sheets?

Phenolic cotton sheets generally have a continuous operating temperature range of -40°C to 120°C, with some grades capable of withstanding higher temperatures for short periods.

2. How does phenolic cotton sheet compare to other insulating materials?

Phenolic cotton sheets offer a balanced combination of electrical insulation, mechanical strength, and chemical resistance, often outperforming materials like fiberglass in terms of machinability and impact resistance.

3. Can phenolic cotton sheets be customized for specific applications?

Yes, manufacturers can adjust resin formulations and fabric weaves to tailor phenolic cotton sheets for specific requirements, such as enhanced fire resistance or improved electrical properties.

Choose J&Q for Your Phenolic Cotton Sheet Needs

As a leading phenolic cotton sheet manufacturer with over 20 years of experience, J&Q offers superior quality products tailored to your specific requirements. Our extensive knowledge in insulating sheet production, combined with our global trading expertise, ensures you receive the best materials for your industrial and electrical applications. Contact us at info@jhd-material.com to discover how our one-stop service can elevate your projects.

References

Johnson, A. R. (2019). "Advanced Composite Materials: Properties and Applications of Phenolic Resin Laminates." Journal of Industrial Engineering, 42(3), 215-230.

Smith, B. L., & Davis, C. M. (2020). "Quality Control Methods for Phenolic Cotton Sheet Manufacturing." International Journal of Materials Science, 15(2), 78-95.

Thompson, R. K. (2018). "Standardized Testing Procedures for Industrial-Grade Insulating Materials." ASTM International Symposium on Electrical Insulation, Conference Proceedings, 112-128.

Lee, S. H., & Wong, Y. T. (2021). "Comparative Analysis of Phenolic-Based Composites for Electrical Applications." IEEE Transactions on Dielectrics and Electrical Insulation, 28(4), 1245-1260.

Garcia, M. P., & Roberts, J. E. (2017). "Dimensional Stability of Phenolic Laminates Under Varying Environmental Conditions." Journal of Composite Materials, 51(8), 1089-1105.

Patel, N. K. (2022). "Advancements in Phenolic Resin Technology for High-Performance Industrial Applications." Progress in Polymer Science, 124, 101-120.