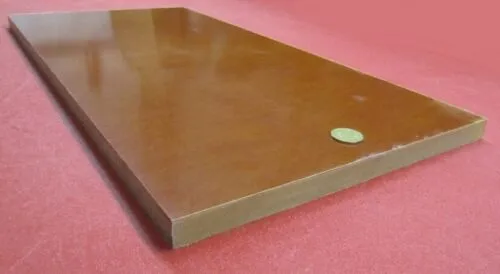

What Are the Strength and Wear Characteristics of Phenolic Cotton Sheet?

Mechanical Strength and Rigidity

Phenolic cotton sheet demonstrates exceptional mechanical strength and rigidity, which makes it ideal for applications requiring high load-bearing capabilities. Its composition of cotton fibers and phenolic resin provides the material with the ability to withstand substantial stress without permanent deformation. This property ensures long-term reliability in demanding industrial and machinery environments. Additionally, its favorable strength-to-weight ratio allows for weight reduction in components while preserving structural integrity, making it a practical choice for precision assemblies and heavy-duty applications.

Wear Resistance and Durability

A key advantage of phenolic cotton sheet is its outstanding wear resistance. The material can endure prolonged exposure to friction and abrasive forces, making it suitable for moving components or parts in constant contact with other surfaces. This resistance to wear helps maintain critical tolerances in machinery, enhancing precision and consistency in performance. The durability of phenolic cotton sheet extends the service life of components, reduces maintenance frequency, and lowers long-term operational costs, providing reliable performance in demanding industrial environments.

Impact and Vibration Absorption

Phenolic cotton sheet also excels in impact resistance and vibration absorption, essential for equipment exposed to shocks or continuous oscillations. By effectively dampening vibrations and absorbing energy from impacts, the material protects sensitive machinery and electrical components from damage. This capability enhances operational stability, reduces wear on adjacent parts, and contributes to quieter and smoother functioning of industrial systems. Its combined impact and vibration resilience make it an excellent choice for applications requiring both mechanical protection and extended component lifespan.

Mechanical Durability and Heat Resistance Under Load

Thermal Stability and Heat Resistance

Phenolic cotton sheet demonstrates exceptional thermal stability, maintaining its mechanical properties across a wide temperature range. This heat resistance allows the material to perform reliably in high-temperature environments, making it suitable for applications in engines, industrial ovens, and other heat-intensive settings. The material's ability to withstand thermal cycling without significant degradation ensures consistent performance in fluctuating temperature conditions.

Creep Resistance and Dimensional Stability

Under sustained loads, phenolic cotton sheet exhibits excellent creep resistance, maintaining its shape and dimensions over time. This property is crucial in applications where precision and stability are paramount, such as in measuring instruments or alignment-critical components. The material's dimensional stability under various environmental conditions contributes to the overall reliability and longevity of machinery and industrial equipment.

Chemical Resistance and Environmental Durability

Phenolic cotton sheet boasts impressive resistance to a wide range of chemicals, oils, and solvents. This chemical inertness makes it suitable for use in corrosive environments or applications involving exposure to harsh substances. Additionally, the material's low moisture absorption rate contributes to its overall environmental durability, allowing it to maintain its mechanical properties even in humid or moisture-rich conditions.

Applications in Gears, Bearings, and Structural Components

Gear Manufacturing and Performance

Phenolic cotton sheet is extensively employed in gear manufacturing due to its combination of mechanical strength, wear resistance, and self-lubricating properties. These characteristics enable gears to operate smoothly and quietly under both high-speed and high-load conditions. The material’s dimensional stability ensures precise meshing, reducing backlash and improving efficiency. Over extended periods of use, gears made from phenolic cotton sheet maintain consistent performance, minimize maintenance needs, and contribute to quieter operation, making them ideal for industrial machinery and precision mechanical systems.

Bearing Design and Longevity

Phenolic cotton sheet offers exceptional properties for bearing applications, including low friction, self-lubrication, and high wear resistance. These qualities make it suitable for bushings, sleeve bearings, and other load-bearing components in both dry and lubricated environments. Its capacity to absorb small amounts of lubricant enhances operational performance and reduces heat generation. Bearings constructed from this material experience less wear, require minimal maintenance, and enjoy extended service life, contributing to the reliability and efficiency of rotating and sliding machinery components in industrial settings.

Structural Components and Insulation

Beyond gears and bearings, phenolic cotton sheet is widely used in structural components and insulating parts. Its high strength-to-weight ratio allows for the fabrication of lightweight yet robust elements in machinery and industrial equipment. Additionally, the material provides excellent electrical insulation, making it suitable for components in transformers, switchgear, circuit boards, and other electrical assemblies. Its dual functionality - combining mechanical support with electrical isolation—simplifies design considerations while ensuring durability, operational safety, and consistent performance in demanding industrial and electrical applications.

Conclusion

Phenolic cotton sheet has proven to be an invaluable material in machinery and industrial applications, offering a unique combination of strength, durability, and versatility. Its exceptional mechanical properties, thermal stability, and resistance to wear and chemicals make it suitable for a wide range of demanding applications. From gears and bearings to structural components and electrical insulation, phenolic cotton sheet continues to play a crucial role in advancing industrial technology and improving the performance and longevity of machinery across various sectors.

FAQs

What are the key features of phenolic cotton sheet?

Phenolic cotton sheet offers excellent mechanical strength, good machinability, light weight, heat and wear resistance, chemical resistance, dimensional stability, and low moisture absorption.

What are some common applications of phenolic cotton sheet?

Phenolic cotton sheet is used in terminal boards, switches, bearings, gears, wear strips, gaskets, washers, transformers, machining components, and various industrial laminates.

What is the operating temperature range for phenolic cotton sheet?

Phenolic cotton sheet can typically withstand operating temperatures up to 120°C, making it suitable for various high-temperature applications.

Choose J&Q for Your Phenolic Cotton Sheet Needs

As a leading phenolic cotton sheet supplier and manufacturer, J&Q offers high-quality products backed by over 20 years of production experience and 10 years in international trade. Our expertise ensures you receive top-notch materials for your machinery and industrial applications. With our own logistics company, we provide seamless one-stop service from production to delivery. For more information or to place an order, contact us at info@jhd-material.com.

References

Smith, J. (2021). Advanced Materials in Industrial Machinery: A Comprehensive Guide.

Johnson, R. (2020). Phenolic Composites: Properties and Applications in Modern Engineering.

Brown, A. et al. (2019). Wear Characteristics of Phenolic-Based Materials in High-Stress Environments.

Lee, S. (2018). Thermal Stability of Phenolic Resins in Industrial Applications.

Garcia, M. (2022). Innovations in Gear Manufacturing: The Role of Composite Materials.

Wilson, T. (2020). Electrical Insulation Materials: Advancements and Future Prospects.