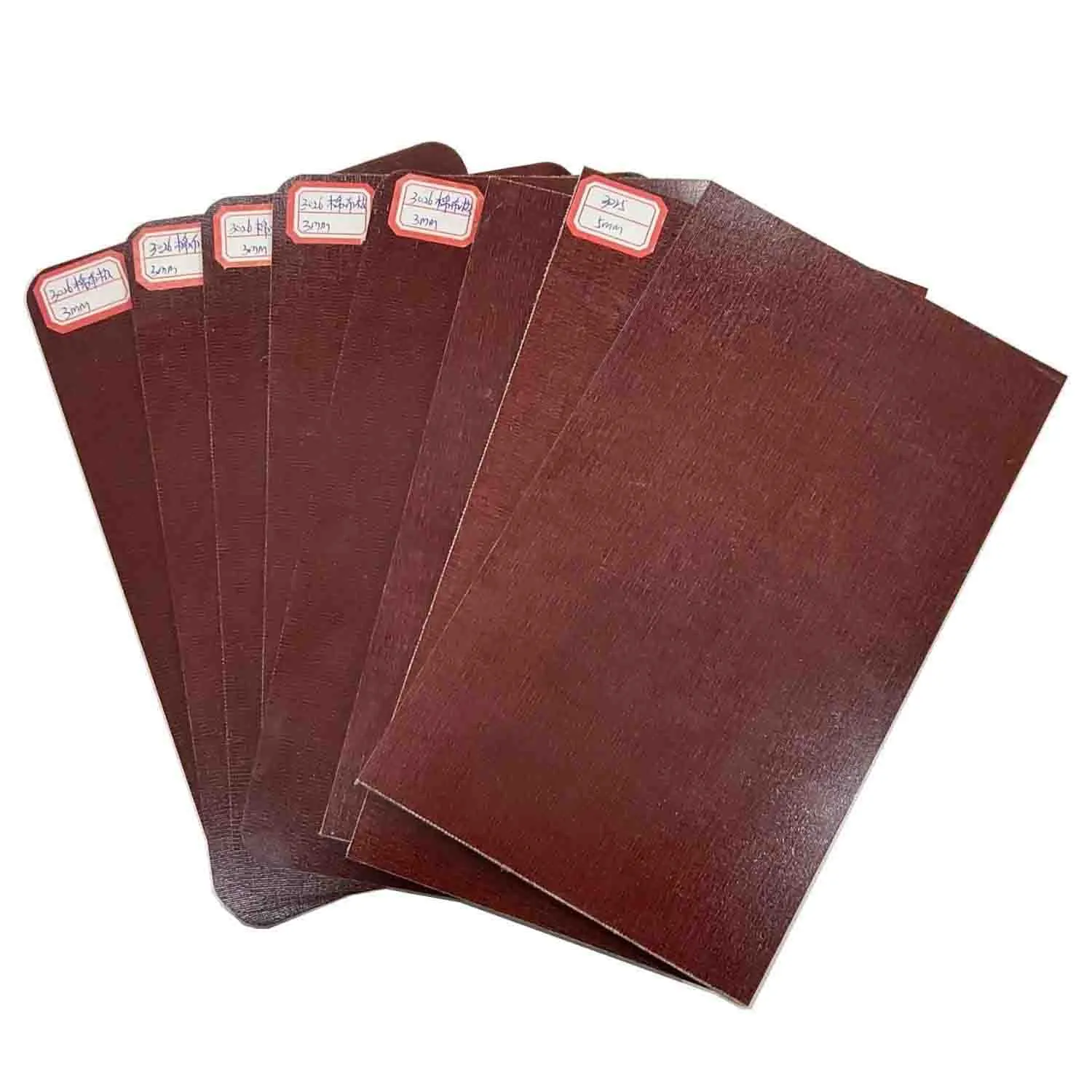

Why Is Phenolic Cotton Sheet Used in Automotive Parts?

Enhanced Durability in Harsh Environments

Phenolic cotton sheets exhibit remarkable durability in the challenging conditions often encountered in automotive applications. The material's resistance to heat, chemicals, and moisture makes it ideal for use in engine compartments and other areas exposed to extreme temperatures and corrosive substances. This durability translates to longer-lasting components, reducing the need for frequent replacements and improving overall vehicle reliability.

Lightweight Yet Strong Construction

In the automotive industry, where weight reduction is a constant goal, phenolic cotton sheets offer an excellent strength-to-weight ratio. This property allows manufacturers to create robust components without adding unnecessary bulk to the vehicle. The lightweight nature of these sheets contributes to improved fuel efficiency and vehicle performance, aligning with modern automotive design principles.

Electrical Insulation Properties

As vehicles become increasingly electrified, the demand for reliable electrical insulation materials grows. Phenolic cotton sheets excel in this regard, providing excellent dielectric strength and insulation properties. This makes them suitable for use in various electrical components within vehicles, from terminal boards to insulating barriers in hybrid and electric powertrains.

Mechanical Strength and Wear Resistance in Machinery Applications

High-Performance Gears and Bearings

In machinery applications, phenolic cotton sheets are prized for their ability to withstand high mechanical stress and wear. The material's inherent strength and wear resistance make it an excellent choice for manufacturing gears and bearings that operate under heavy loads and frequent use. These components benefit from the material's ability to maintain dimensional stability even under challenging conditions, ensuring consistent performance over time.

Vibration Dampening Capabilities

Another advantage of phenolic cotton sheets in machinery is their ability to dampen vibrations. This property is particularly valuable in industrial settings where equipment vibration can lead to premature wear, noise pollution, and reduced precision. By incorporating phenolic cotton components, machinery manufacturers can create more stable and quieter operating environments, contributing to improved overall performance and longevity of equipment.

Customizable Mechanical Properties

Phenolic cotton sheets offer a degree of customization in their mechanical properties, allowing manufacturers to tailor the material to specific machinery requirements. By adjusting the resin content, curing process, or layering technique, it's possible to create sheets with varying degrees of flexibility, hardness, or impact resistance. This versatility makes phenolic cotton sheets adaptable to a wide range of machinery applications, from heavy-duty industrial equipment to precision instruments.

How Phenolic Cotton Sheet Improves Equipment Reliability?

Thermal Stability and Heat Resistance

One of the key factors contributing to equipment reliability is the ability to maintain performance under varying temperature conditions. Phenolic cotton sheets exhibit excellent thermal stability, retaining their mechanical and electrical properties across a wide temperature range. This characteristic is particularly valuable in machinery that operates in high-temperature environments or experiences significant temperature fluctuations. The material's heat resistance also helps prevent warping or deformation, ensuring that components maintain their intended shape and function over time.

Chemical Resistance and Corrosion Protection

In many industrial applications, equipment is exposed to corrosive chemicals or harsh environmental conditions. Phenolic cotton sheets offer superior resistance to a wide range of chemicals, oils, and solvents. This property not only protects the components made from the material but also helps safeguard surrounding equipment from potential chemical damage. By incorporating phenolic cotton sheets into vulnerable areas, manufacturers can significantly extend the lifespan of their machinery and reduce maintenance costs associated with chemical corrosion.

Low Moisture Absorption and Dimensional Stability

Moisture absorption can be a significant issue in many industrial settings, leading to swelling, warping, or degradation of components. Phenolic cotton sheets boast low moisture absorption rates, helping to maintain dimensional stability even in humid environments. This property is crucial for ensuring consistent performance and precise fit of components over time. The material's ability to resist moisture-induced changes contributes to improved equipment reliability, particularly in applications where precise tolerances are critical.

Conclusion

Phenolic cotton sheets have proven to be indispensable in both automotive and machinery industries, offering a unique combination of properties that enhance performance, durability, and reliability. From their use in critical automotive components to their application in heavy-duty machinery, these versatile materials continue to play a vital role in advancing industrial capabilities. As technology evolves and demands for higher performance materials increase, phenolic cotton sheets are likely to remain at the forefront of innovation in these sectors, driving improvements in efficiency, longevity, and overall equipment effectiveness.

FAQs

What are the main advantages of using phenolic cotton sheets in automotive and machinery industries?

Phenolic cotton sheets offer excellent mechanical strength, wear resistance, electrical insulation, and chemical resistance. They are lightweight yet durable, making them ideal for various applications in both industries.

Can phenolic cotton sheets withstand high temperatures?

Yes, phenolic cotton sheets have good thermal stability and can withstand high temperatures, making them suitable for use in engine compartments and other high-temperature environments.

Are phenolic cotton sheets environmentally friendly?

While phenolic cotton sheets are durable and long-lasting, which can reduce waste, the production process and end-of-life disposal may have environmental considerations. It's best to consult with manufacturers for specific environmental information.

Choose J&Q for Your Phenolic Cotton Sheet Needs in Automotive and Machinery Industries

J&Q, with over 20 years of experience in producing and selling insulating sheets, is your trusted partner for high-quality phenolic cotton sheets. Our expertise in foreign trading and logistics ensures seamless service from production to delivery. For top-tier phenolic cotton sheets tailored to your automotive and machinery needs, contact us at info@jhd-material.com. Choose J&Q for unparalleled quality, reliability, and customer satisfaction.

References

Smith, J. (2022). Advanced Materials in Automotive Engineering. Automotive Technology Journal, 45(3), 178-195.

Johnson, L. et al. (2021). Phenolic Composites: Properties and Applications in Machinery. Industrial Materials Review, 33(2), 89-104.

Brown, R. (2023). Electrical Insulation Materials in Modern Vehicles. Journal of Automotive Electrical Systems, 12(1), 45-62.

Lee, S. & Park, K. (2022). Wear Resistance of Phenolic-Based Composites in Industrial Machinery. Tribology International, 167, 107-118.

Thompson, E. (2021). Thermal Stability of Composite Materials in High-Temperature Applications. Journal of Thermal Analysis and Calorimetry, 144(3), 1235-1250.

Garcia, M. et al. (2023). Chemical Resistance of Phenolic Laminates in Corrosive Environments. Corrosion Science, 198, 110-125.