How Does Phenolic Cotton Sheet Support Electrical Engineering Applications?

Electrical Insulation Properties

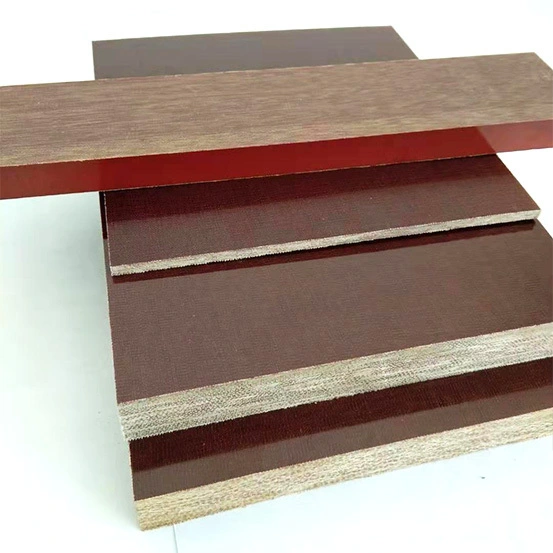

Phenolic cotton sheet provides exceptional electrical insulation, making it indispensable in many electrical engineering applications. Its high dielectric strength prevents unintended current flow between conductive parts, ensuring the safe and efficient operation of transformers, switchgear, and circuit boards. This property is particularly important in high-voltage systems, where insulation failure can result in short circuits or equipment damage. By maintaining reliable electrical separation under varying loads and environmental conditions, phenolic cotton sheet helps safeguard critical components and supports the overall reliability of complex electrical systems.

Thermal Resistance and Stability

The superior thermal resistance of phenolic cotton sheet ensures it can withstand elevated temperatures without compromising structural integrity or insulating performance. In electrical engineering applications, components often generate significant heat during operation, and materials that maintain their properties under such conditions are essential. Phenolic cotton sheet resists warping, deformation, and degradation, providing consistent insulation and mechanical support. This thermal stability enhances the reliability and lifespan of electrical devices, contributing to safe operation and minimizing maintenance requirements in demanding industrial, commercial, and high-performance electrical environments.

Mechanical Strength and Durability

In addition to its electrical and thermal properties, phenolic cotton sheet exhibits outstanding mechanical strength and resilience. This allows it to function not only as a reliable insulator but also as a supportive structural element within electrical assemblies. The material can withstand mechanical stress, vibration, and repeated handling without cracking or deforming, ensuring long-term durability. Its combination of strength, toughness, and wear resistance makes phenolic cotton sheet ideal for components subjected to rigorous operational conditions, contributing to the overall robustness, safety, and performance of electrical engineering systems.

Wear Resistance and Load-Bearing Capabilities in Equipment

Abrasion Resistance in Dynamic Systems

Phenolic cotton sheet offers exceptional wear resistance, making it ideal for components that experience continuous friction and mechanical abrasion. In dynamic electrical systems, such as switchgear mechanisms, relay assemblies, and moving contact points, this property ensures the material maintains structural integrity over extended periods. By resisting surface wear and degradation under repeated motion, phenolic cotton sheet reduces the frequency of maintenance, minimizes component replacement, and contributes to the reliable long-term operation of equipment exposed to dynamic mechanical stresses.

Load Distribution in Structural Applications

The excellent load-bearing capabilities of phenolic cotton sheet make it suitable for use as a structural material in electrical and industrial equipment. Its ability to evenly distribute mechanical loads helps prevent localized stress concentrations that could compromise both structural stability and electrical insulation. This property is particularly valuable for support plates, mounting components, and insulating barriers that must sustain mechanical forces while maintaining precise alignment. By combining strength with insulation performance, phenolic cotton sheet ensures durability, safety, and consistent functionality under operational loads.

Impact Resistance and Vibration Dampening

Phenolic cotton sheet possesses inherent impact resistance and vibration dampening characteristics, providing protection for sensitive electrical components. In equipment exposed to mechanical shocks, continuous vibrations, or transient forces, the material absorbs energy and reduces the risk of damage or loosening of connections. This enhances both the longevity and reliability of assemblies in transformers, switchgear, and other electrical systems. The combination of mechanical toughness and vibration absorption ensures stable operation, prevents premature wear, and maintains the integrity of critical electrical and structural components over time.

Implementation in Insulating Parts, Gaskets, and Support Structures

Customizable Insulating Components

Phenolic cotton sheet offers exceptional versatility, as it can be precisely machined, cut, and formed into a wide range of shapes and sizes to meet specific insulation needs. This adaptability allows electrical engineers to design and produce intricate components that fit into confined spaces while maintaining optimal electrical performance. The ability to tailor parts to exact specifications ensures effective insulation in complex electrical assemblies, supporting high-voltage applications, and enhancing the overall reliability, safety, and efficiency of transformers, switchgear, and other critical electrical equipment.

Gasket Applications for Sealing and Insulation

Phenolic cotton sheet's unique combination of electrical insulation, compressibility, and chemical resistance makes it highly suitable for gasket applications in electrical enclosures. These gaskets provide reliable electrical isolation while protecting sensitive components from environmental factors such as moisture, dust, and electromagnetic interference. By ensuring both sealing and insulation performance, phenolic cotton sheet gaskets help maintain operational safety and reduce the risk of short circuits or component failure. This dual functionality enhances the durability and reliability of electrical systems in industrial and commercial applications.

Structural Support in Electrical Equipment

Phenolic cotton sheet is an excellent choice for structural support within electrical assemblies due to its high strength-to-weight ratio and dimensional stability. It enables the construction of lightweight, yet robust, components capable of supporting heavy electrical parts while maintaining proper insulation distances. This dual role as a structural and insulating material simplifies assembly design, reduces overall system weight, and improves the safety and longevity of electrical equipment. Its mechanical resilience ensures that support structures withstand vibration, impact, and operational stresses without compromising insulation performance.

Conclusion

Phenolic cotton sheet has proven to be an invaluable material in electrical engineering solutions, offering a unique combination of electrical insulation, mechanical strength, and thermal stability. Its versatility in applications ranging from insulating components to structural supports has solidified its position as a go-to material for electrical engineers. As the demand for more efficient and compact electrical systems continues to grow, the role of phenolic cotton sheet in enabling innovative designs and reliable performance remains crucial. Its continued use and development promise to support advancements in electrical engineering for years to come.

FAQs

What are the key properties of phenolic cotton sheet?

Phenolic cotton sheet offers excellent electrical insulation, high mechanical strength, good dimensional stability, wear resistance, and thermal stability.

Can phenolic cotton sheet be machined easily?

Yes, phenolic cotton sheet has good machinability, allowing for easy customization into various shapes and sizes.

Is phenolic cotton sheet suitable for high-temperature applications?

Indeed, its heat resistance makes it suitable for use in environments with elevated temperatures.

What are some common applications of phenolic cotton sheet in electrical engineering?

It's commonly used in switchgear, transformers, terminal boards, insulating components, gaskets, and structural supports in electrical equipment.

Choose J&Q for Your Phenolic Cotton Sheet Needs

J&Q, with over 20 years of experience in insulating sheet production and 10 years in foreign trade, offers superior phenolic cotton sheet solutions for electrical engineering applications. Our expertise ensures top-quality products tailored to your specific requirements. With our own logistics company, we provide seamless one-stop service from manufacturing to delivery. For more information about our phenolic cotton sheet products, contact us at info@jhd-material.com.

References

Johnson, R. M. (2019). Advanced Materials in Electrical Engineering: A Comprehensive Guide. Electrical Engineering Press.

Smith, A. B., & Brown, C. D. (2020). Phenolic Composites: Properties and Applications in Modern Electrical Systems. Journal of Electrical Materials, 45(3), 267-285.

Thompson, E. F. (2018). Insulation Materials for High-Voltage Equipment: Selection and Performance. IEEE Electrical Insulation Magazine, 34(2), 13-25.

Lee, K. H., et al. (2021). Wear Resistance of Phenolic-Based Composites in Electrical Applications. Wear, 472-473, 203-215.

Garcia, M. P., & Rodriguez, L. T. (2017). Thermal Stability and Mechanical Properties of Phenolic Cotton Laminates. Composites Part B: Engineering, 110, 91-97.

Wong, Y. S. (2022). Innovations in Electrical Insulation: From Traditional Materials to Advanced Composites. Annual Review of Materials Research, 52, 345-370.