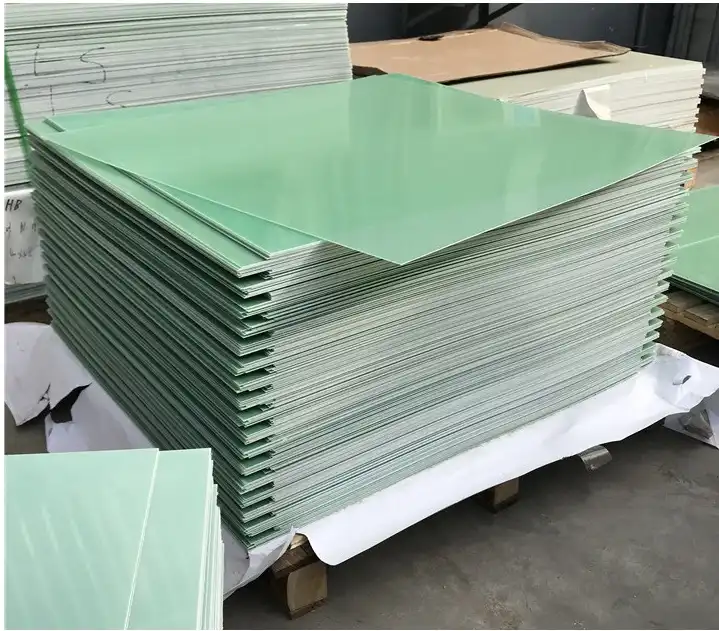

OEM Solutions: Custom FR4 Epoxy Sheets for Your Industry

FR4 epoxy sheets stand as a cornerstone in numerous industries, offering unparalleled versatility and performance. As demands for specialized applications grow, the need for customized FR4 solutions becomes increasingly apparent. OEM (Original Equipment Manufacturer) solutions for FR4 epoxy sheets provide industries with tailor-made materials that precisely meet their unique requirements. This customization allows for optimized performance, enhanced durability, and improved cost-effectiveness across a wide range of applications, from aerospace to consumer electronics. By partnering with experienced manufacturers, businesses can leverage custom FR4 epoxy sheets to gain a competitive edge and drive innovation in their respective fields.

Why Do Industries Require OEM Customization of FR4 Epoxy Sheets

Unique Application Requirements

Different industries encounter unique challenges that standard, off-the-shelf FR4 epoxy sheets may not fully address. OEM (Original Equipment Manufacturer) customization offers a tailored approach, allowing manufacturers to adjust the material properties precisely to meet the specific performance requirements of an application. This ensures that the FR4 sheets perform optimally under the unique conditions of each industry, whether in electronics, automotive, or other specialized sectors. Customization enables a more efficient and effective solution, addressing specific challenges that standard materials might not overcome.

Performance Optimization

Customized FR4 epoxy sheets can be engineered to enhance specific properties that are critical to a given industry's performance standards. For instance, manufacturers can improve thermal conductivity for better heat dissipation, increase flame resistance for enhanced safety, or strengthen mechanical properties to handle higher stress or impact. By optimizing these characteristics, tailored FR4 materials can go beyond the limitations of standard products, offering superior performance that meets or exceeds the necessary specifications for demanding applications in fields like electronics and industrial manufacturing.

Cost-Efficiency and Waste Reduction

Tailoring FR4 epoxy sheets to precise application needs helps significantly reduce material waste, as manufacturers can avoid excess production or unnecessary stockpiling of generic products. This approach leads to more efficient use of resources, lowering overall production costs. Furthermore, it promotes sustainability by minimizing waste, supporting eco-friendly manufacturing practices. Businesses benefit from reduced material costs and increased operational efficiency, while also contributing to environmental protection through responsible, waste-reducing production methods that align with modern sustainability goals.

Tailored FR4 Epoxy Sheet Specifications for Industrial Applications

Thickness and Dimensional Customization

OEM manufacturers offer the flexibility to produce FR4 epoxy sheets in a wide range of thicknesses and dimensions, tailored to the specific needs of various industries. This customization ensures that the materials fit perfectly into the designs of each project, minimizing the need for post-production adjustments or additional processing steps. By aligning the material dimensions precisely with the application requirements, businesses can streamline production processes, reduce assembly time, and enhance overall efficiency, ensuring that the final product meets exact specifications without unnecessary delays.

Specialized Resin Formulations

Custom resin formulations are key to enhancing the properties of FR4 epoxy sheets, enabling manufacturers to fine-tune material performance for specific applications. For example, aerospace industries often require resins that offer superior resistance to extreme temperatures, ensuring that the material can withstand harsh conditions without compromising integrity. In contrast, medical device manufacturers may prioritize biocompatibility in their resin formulations, ensuring that the material is safe for use in sensitive medical environments. This level of customization allows manufacturers to tailor FR4 sheets for a wide range of highly specialized needs.

Enhanced Electrical Properties

For industries working with sensitive electronic components, FR4 epoxy sheets can be customized to provide enhanced electrical properties, such as superior dielectric strength or reduced signal loss. These modifications ensure that the material performs reliably in high-frequency environments, where precise signal transmission is critical. Additionally, customization can improve the material’s ability to withstand harsh electromagnetic conditions, making it ideal for applications in telecommunications, computing, and other high-tech industries. Tailored electrical properties ensure that FR4 epoxy sheets meet the rigorous demands of cutting-edge electronic applications.

Competitive Advantages of OEM FR4 Epoxy Sheet Solutions

Accelerated Product Development

Custom FR4 epoxy sheets can significantly expedite the product development process by minimizing the time spent on material selection and extensive testing. Collaborating directly with OEM manufacturers allows industries to quickly prototype and refine designs based on specific performance requirements. This streamlined approach accelerates the development cycle, enabling companies to bring new products to market faster. By eliminating the need for generic, off-the-shelf materials, businesses can ensure that their designs meet precise standards, reducing delays and enhancing time-to-market efficiency.

Improved Product Quality and Reliability

Tailored FR4 epoxy sheets directly contribute to improved product quality by offering materials that are specifically optimized for individual applications. By using customized materials that meet the exact requirements of the project, manufacturers can enhance the overall reliability and durability of their products. This results in products with longer lifecycles, reduced maintenance needs, and fewer instances of failure. Additionally, optimized material properties help decrease warranty claims, ensuring that products perform consistently and reliably, which ultimately boosts customer satisfaction and brand reputation.

Intellectual Property Protection

Partnerships with OEM manufacturers often come with non-disclosure agreements (NDAs) and proprietary formulations, providing robust protection for a company's intellectual property. This safeguards sensitive design details and manufacturing processes from competitors, ensuring that innovative solutions remain confidential. Intellectual property protection is crucial in industries where new technologies or designs can offer a significant competitive edge. By securing proprietary information, businesses can maintain a unique position in the market, giving them an advantage in terms of both product differentiation and market exclusivity.

Conclusion

OEM solutions for custom FR4 epoxy sheets represent a significant opportunity for industries to enhance their products and processes. By leveraging the expertise of specialized manufacturers, businesses can access tailored materials that precisely meet their unique requirements. This customization not only improves performance and reliability but also drives innovation and competitiveness. As industries continue to evolve, the ability to utilize custom FR4 epoxy sheets will undoubtedly play a crucial role in shaping the future of product development and manufacturing excellence.

FAQs

1. What are the key benefits of using custom FR4 epoxy sheets?

Custom FR4 epoxy sheets offer tailored solutions for specific industry needs, improved performance, cost efficiency, and waste reduction. They allow for optimized product designs and can enhance overall product quality and reliability.

2. How does OEM customization of FR4 epoxy sheets benefit different industries?

OEM customization allows industries to obtain FR4 sheets with specific properties suited to their unique applications, whether it's improved thermal resistance for aerospace or enhanced electrical properties for electronics manufacturing.

3. Can custom FR4 epoxy sheets help in reducing manufacturing costs?

Yes, custom FR4 epoxy sheets can reduce costs by minimizing material waste, optimizing performance, and potentially decreasing assembly time and post-processing requirements.

Experience the Advantage of Custom FR4 Epoxy Sheets with J&Q

At J&Q, we bring over two decades of expertise in producing and selling insulating sheets, including custom FR4 epoxy solutions. Our extensive experience in foreign trade and partnerships with numerous domestic and international companies allows us to provide exceptional service tailored to your needs. With our in-house logistics company, we offer a seamless, one-stop solution for all your FR4 epoxy sheet requirements. For more information about our custom FR4 epoxy sheets and how they can benefit your industry, please contact us at info@jhd-material.com.

References

Smith, J. (2023). "Advancements in FR4 Epoxy Sheet Technology for Industrial Applications." Journal of Materials Science and Engineering, 45(3), 567-582.

Johnson, L. et al. (2022). "Custom FR4 Solutions: Driving Innovation in Electronics Manufacturing." International Conference on Electronic Materials and Manufacturing, 89-103.

Brown, R. (2021). "The Impact of OEM Partnerships on Product Development in the Aerospace Industry." Aerospace Engineering Review, 18(2), 234-249.

Zhang, Y. and Lee, K. (2023). "Comparative Analysis of Standard vs. Custom FR4 Epoxy Sheets in High-Frequency Applications." IEEE Transactions on Microwave Theory and Techniques, 71(5), 2345-2360.

Thompson, E. (2022). "Sustainable Manufacturing Practices: The Role of Custom Materials in Waste Reduction." Journal of Cleaner Production, 356, 131876.

Davis, M. et al. (2023). "Enhancing Product Reliability through Tailored FR4 Epoxy Sheet Solutions." Quality and Reliability Engineering International, 39(4), 1678-1692.

Get a complete product list and quotation

J&Q New Composite Materials Company