What Performance Parameters Define NEMA CE Sheet Compliance

Electrical Properties and Insulation Effectiveness

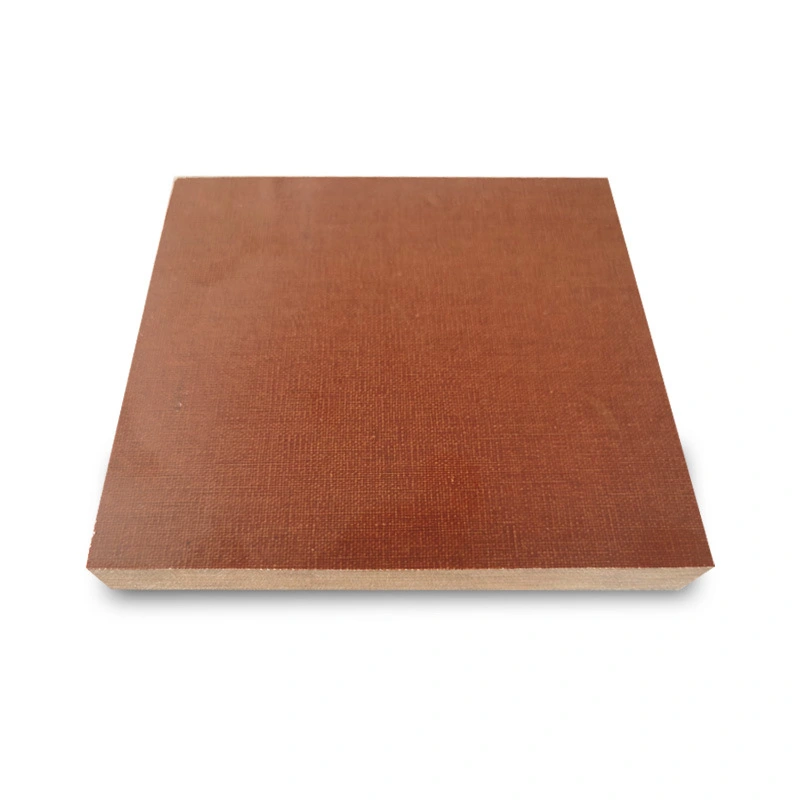

NEMA CE sheets must exhibit exceptional electrical insulation properties to comply with industry standards. The dielectric strength, measured in kilovolts per millimeter, is a critical parameter that determines the material's ability to withstand high voltages without breakdown. Additionally, the volume and surface resistivity are evaluated to ensure minimal current leakage across the sheet's surface and through its bulk. These electrical characteristics are fundamental to the sheet's performance in various applications, from printed circuit boards to high-voltage equipment insulation.

Mechanical Strength and Durability Metrics

The mechanical integrity of NEMA CE sheets is crucial for their long-term reliability. Compliance standards assess the flexural strength, which indicates the material's resistance to bending forces. Impact resistance is another vital metric, ensuring the sheet can withstand sudden mechanical stresses without fracturing. Tensile strength tests evaluate the material's ability to resist longitudinal stress, while compressive strength measurements gauge its capacity to withstand crushing forces. These mechanical properties collectively determine the sheet's suitability for applications involving physical stress and strain.

Thermal Performance and Flame Resistance

Thermal stability is a key aspect of NEMA CE sheet compliance. The heat deflection temperature (HDT) is measured to determine the point at which the material begins to soften under load at elevated temperatures. Flame resistance is another critical parameter, often evaluated using the UL 94 flammability test. This test assesses the material's ability to self-extinguish and resist flame propagation. The coefficient of thermal expansion is also considered, as it affects the dimensional stability of the sheet when subjected to temperature fluctuations in operational environments.

Dimensional Accuracy and Electrical Strength Testing Procedures

Precision Measurement Techniques for Sheet Dimensions

Ensuring dimensional accuracy is paramount in NEMA CE sheet production. Advanced metrology equipment, such as coordinate measuring machines (CMMs), is employed to verify sheet dimensions with micrometer precision. Laser interferometry may be utilized for ultra-precise thickness measurements, capable of detecting variations as small as a few microns. Edge straightness and flatness are assessed using optical comparators and surface profilometers, ensuring that the sheets meet the stringent tolerances required for seamless integration into complex electrical assemblies.

Dielectric Strength Assessment Methodologies

Dielectric strength testing is a cornerstone of NEMA CE sheet quality control. The step-by-step voltage test method involves gradually increasing the applied voltage across the sheet until breakdown occurs. Alternatively, the short-time test applies the full test voltage for a specified duration to verify insulation integrity. These tests are conducted in carefully controlled environments to minimize the influence of external factors such as humidity and temperature. Specialized high-voltage test equipment, complete with safety interlocks and precise voltage regulation, is utilized to ensure accurate and repeatable results.

Non-Destructive Evaluation Techniques

Non-destructive testing (NDT) methods play a crucial role in assessing NEMA CE sheet quality without compromising the integrity of the material. Ultrasonic scanning is employed to detect internal defects or delaminations that may not be visible on the surface. Thermography can reveal inconsistencies in thermal conductivity, which may indicate variations in material composition or density. Eddy current testing is another valuable NDT technique used to identify surface and near-surface flaws in conductive materials, ensuring the homogeneity and structural integrity of the CE sheets.

Quality Control Methods for Consistent NEMA-Grade Production

Statistical Process Control in Manufacturing

Implementing statistical process control (SPC) is essential for maintaining consistent NEMA-grade CE sheet production. Control charts are utilized to monitor key process variables, such as resin mixing ratios and curing temperatures, in real-time. X-bar and R charts track the mean and range of critical dimensions, ensuring that the production remains within specified control limits. Process capability indices (Cpk) are calculated to assess the ability of the manufacturing process to consistently meet NEMA specifications. By analyzing these statistical indicators, manufacturers can proactively identify and address process drift before it results in non-compliant sheets.

Automated Inspection Systems and Machine Vision

Advanced automated inspection systems leverage machine vision technology to enhance quality control in NEMA CE sheet production. High-resolution cameras and sophisticated image processing algorithms inspect sheets for surface defects, such as pinholes or inclusions, at production line speeds. Laser triangulation sensors can perform rapid, non-contact thickness measurements across the entire sheet surface, ensuring uniformity. These automated systems not only increase inspection throughput but also provide consistent, objective evaluations free from human error or fatigue. Data from these inspections is often integrated into manufacturing execution systems (MES) for comprehensive quality tracking and traceability.

Material Composition Verification Techniques

Ensuring the correct material composition is crucial for NEMA CE sheet compliance. Fourier Transform Infrared Spectroscopy (FTIR) is employed to verify the chemical composition of the resin system, detecting any deviations from the specified formulation. Thermogravimetric analysis (TGA) provides insights into the material's thermal stability and helps quantify the reinforcement content. X-ray fluorescence (XRF) spectroscopy can be used to detect and measure trace elements that may affect the sheet's electrical or mechanical properties. These analytical techniques, combined with rigorous raw material quality control, help maintain the consistency and performance of NEMA CE sheets across production batches.

Conclusion

NEMA CE sheet quality inspection standards are the bedrock of reliable electrical insulation materials. By rigorously adhering to these standards, manufacturers ensure that their products meet the exacting requirements of diverse industries. The comprehensive testing procedures, from electrical strength assessments to dimensional accuracy verifications, guarantee the consistent performance of CE sheets in critical applications. As technology advances, these standards continue to evolve, driving innovation in materials science and manufacturing processes. Ultimately, the stringent quality control measures outlined in NEMA standards safeguard the integrity of electrical systems worldwide.

FAQs

1. What are the key electrical properties tested in NEMA CE sheets?

The main electrical properties tested include dielectric strength, volume and surface resistivity, and dielectric constant.

2. How often should NEMA CE sheets be inspected during production?

Continuous in-line inspection is recommended, with batch sampling for more detailed tests at regular intervals, typically every hour or per production lot.

3. Can NEMA CE sheets be customized for specific applications?

Yes, NEMA CE sheets can be tailored to meet specific requirements while still adhering to the overall NEMA standards for quality and performance.

Experience Premium NEMA CE Sheets from J&Q

At J&Q, a leading NEMA CE sheet manufacturer, we pride ourselves on delivering top-quality NEMA CE sheets that exceed industry standards. Our state-of-the-art manufacturing process ensures consistent production of high-performance industrial insulation materials. With over two decades of experience and a global presence, we are a trusted electrical laminate manufacturer offering unparalleled expertise in NEMA-grade products. For premium NEMA CE sheets that meet your exacting specifications, contact our team at info@jhd-material.com. Trust J&Q for reliability, precision, and superior customer service in all your electrical insulation needs.

References

National Electrical Manufacturers Association. (2021). NEMA LI 1: Industrial Laminated Thermosetting Products.

American Society for Testing and Materials. (2020). ASTM D149: Standard Test Method for Dielectric Breakdown Voltage and Dielectric Strength of Solid Electrical Insulating Materials at Commercial Power Frequencies.

Institute of Electrical and Electronics Engineers. (2019). IEEE 43: IEEE Recommended Practice for Testing Insulation Resistance of Electric Machinery.

Underwriters Laboratories. (2022). UL 94: Standard for Tests for Flammability of Plastic Materials for Parts in Devices and Appliances.

International Electrotechnical Commission. (2021). IEC 60243-1: Electrical strength of insulating materials - Test methods - Part 1: Tests at power frequencies.

Society of Plastics Engineers. (2020). Handbook of Plastics Testing and Failure Analysis, 4th Edition.