What Certifications and Quality Systems Indicate Reliable FR4 Manufacturing

Industry-Standard Certifications

Reputable FR4 suppliers distinguish themselves by holding key industry-standard certifications, which serve as independent verification of their operational and product integrity. The foundational certification is typically ISO 9001, which validates a robust Quality Management System ensuring consistent processes and continuous improvement. Beyond this, specific product-oriented certifications are crucial. UL 94 certification is essential as it officially classifies the material's flame retardancy performance, a critical safety requirement for PCBs. Furthermore, compliance with IPC-4101 guarantees that the laminate's properties, such as glass transition temperature (Tg) and dielectric constant, meet the rigorous specifications set by the electronics industry. These credentials collectively demonstrate a supplier's unwavering commitment to quality, safety, and reliability in FR4 epoxy sheet production, providing customers with essential confidence in the base materials for their applications.

Quality Control Processes

A supplier's commitment to quality must be actively demonstrated through comprehensive and documented Quality Control (QC) processes. It is critical to evaluate if their quality assurance system encompasses the entire production lifecycle, from raw material inspection to final product release. This involves regular testing of incoming materials to ensure purity and specification adherence, continuous in-process monitoring to control manufacturing variables, and rigorous final inspection of the finished FR4 epoxy sheets. Suppliers who invest in advanced testing equipment—for measuring parameters like dimensional stability, electrical strength, and moisture absorption - and maintain detailed documentation for traceability are far more likely to deliver FR4 epoxy sheets with exceptional batch-to-batch consistency. This meticulous approach to QC is a direct indicator of a supplier's reliability and their capability to provide high-performance, dependable FR4 epoxy sheets.

Environmental and Safety Compliance

In today's global market, a supplier's adherence to environmental and safety regulations is non-negotiable and reflects their corporate responsibility. Prospective buyers should prioritize suppliers who proactively comply with international directives such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals). RoHS compliance certifies that the FR4 epoxy sheets are manufactured without the use of restricted hazardous materials like lead and mercury, making them safer for use in electronic products. REACH registration addresses the broader management of chemical substances throughout the supply chain. Adherence to these standards not only ensures the materials are environmentally friendly and safe for end-users but also mitigates legal and market access risks for the OEMs who incorporate these laminates into their products.

Material Consistency, Supply Stability, and Technical Support Evaluation

Material Consistency Assessment

Maintaining consistent quality in FR4 epoxy sheets is essential for achieving stable PCB performance. Evaluate whether the supplier can deliver uniform thickness, dielectric constant, and glass transition temperature across multiple batches. Even slight variations can affect signal integrity or thermal reliability in high-density circuit designs. Reliable suppliers use precise process controls, advanced testing methods, and standardized production systems to ensure every sheet meets the same mechanical and electrical specifications, reducing variability in final PCB assemblies.

Supply Chain Stability

A dependable supply chain is vital for uninterrupted PCB production and timely delivery. Assess each supplier's production scale, logistics efficiency, and inventory management capabilities. Suppliers with multiple manufacturing locations or well-established sourcing networks for raw materials, such as epoxy resins and fiberglass, can better withstand market fluctuations and material shortages. Prioritizing FR4 epoxy sheet suppliers with proven delivery records helps prevent costly production delays and ensures business continuity during high-demand or supply-constrained periods.

Technical Support and Innovation

Beyond material supply, strong technical support can significantly enhance design and production efficiency. Suppliers that offer engineering consultation, troubleshooting assistance, and material optimization guidance contribute to better end-product performance. Those committed to research and development can introduce improved FR4 epoxy formulations with higher thermal resistance or reduced signal loss. Partnering with such forward-thinking suppliers keeps your manufacturing process aligned with emerging technologies in the fast-evolving electronics industry.

Building Long-Term Partnerships with Verified FR4 Suppliers

Communication and Responsiveness

Strong communication forms the foundation of any reliable supplier relationship. When selecting an FR4 epoxy sheet supplier, assess how promptly they respond to technical inquiries, quotation requests, or production updates. A supplier that provides clear documentation, material data, and proactive support demonstrates professionalism and reliability. Open collaboration also enables customized solutions for unique project requirements, helping optimize material performance and ensuring that production schedules and specifications are met consistently.

Financial Stability and Pricing Transparency

Financially secure suppliers offer greater long-term reliability and pricing consistency. When evaluating FR4 epoxy sheet providers, look for transparent pricing structures and detailed cost breakdowns to avoid hidden charges. Extremely low prices can sometimes signal inferior material quality or unstable supply chains. A financially sound supplier is more likely to maintain steady operations, invest in quality assurance, and deliver consistent performance over time, providing a dependable foundation for ongoing business cooperation.

Continuous Improvement and Feedback Integration

An ideal FR4 epoxy sheet supplier continuously seeks to enhance both product quality and customer experience. Evaluate whether the supplier invests in modern equipment, refines production processes, or develops advanced material formulations. Those who actively seek and apply customer feedback show adaptability and a long-term partnership mindset. This ongoing improvement ensures that their products evolve alongside technological advancements, keeping your manufacturing operations efficient, competitive, and aligned with industry standards.

Conclusion

Selecting the right FR4 epoxy sheets supplier is crucial for ensuring the quality and reliability of your electronic products. By carefully evaluating certifications, quality systems, material consistency, supply stability, and technical support capabilities, you can identify suppliers who meet your specific needs. Building long-term partnerships with verified FR4 epoxy sheets manufacturers not only secures a stable supply of high-quality materials but also fosters innovation and continuous improvement. Remember, the right supplier is not just a vendor but a strategic partner in your success.

FAQs

1. What is FR4 epoxy sheet?

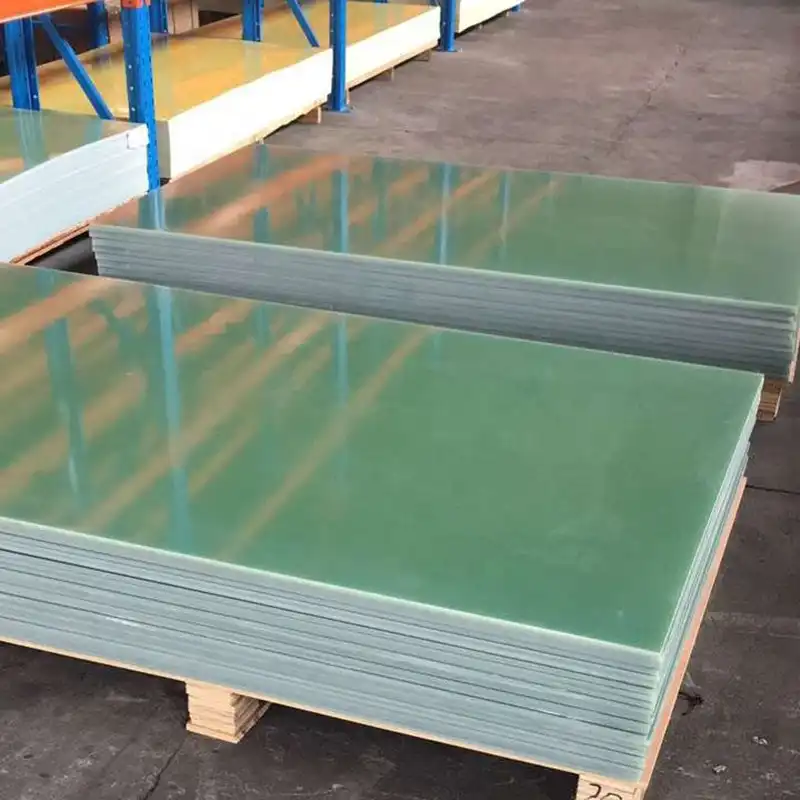

FR4 epoxy sheet is a composite material made of woven fiberglass cloth impregnated with an epoxy resin. It's widely used in the electronics industry for printed circuit boards due to its excellent electrical insulation properties, flame resistance, and mechanical strength.

2. Why is FR4 popular in PCB manufacturing?

FR4 is popular because it offers a balance of electrical, thermal, and mechanical properties at a reasonable cost. It's flame-retardant, has good dimensional stability, and performs well in various environmental conditions.

3. How thick are FR4 sheets typically?

FR4 sheets are available in various thicknesses, typically ranging from 0.2mm to 50mm, depending on the application requirements.

Choose J&Q for Your FR4 Epoxy Sheet Needs

J&Q, a trusted FR4 epoxy sheet manufacturer, brings over 20 years of experience in insulating sheet production and 10 years in foreign trade to deliver superior FR4 epoxy sheets. As a professional insulation material supplier, our in-house logistics company ensures seamless one-stop service from production to delivery. For high-quality FR4 materials and expert support, contact us at info@jhd-material.com. Trust J&Q, your reliable FR4 manufacturer and supplier, for all your FR4 sheet requirements.

References

Smith, J. (2022). "Evaluating FR4 Suppliers: A Comprehensive Guide for Electronics Manufacturers"

Johnson, M. et al. (2021). "Quality Control Processes in FR4 Production: Industry Best Practices"

Lee, S. (2023). "The Impact of Supplier Selection on PCB Manufacturing Efficiency"

Thompson, R. (2022). "FR4 Material Innovations: Trends and Future Prospects"

Garcia, A. (2021). "Building Resilient Supply Chains in the Electronics Industry"

Wilson, D. (2023). "Certifications and Standards in FR4 Manufacturing: What You Need to Know"