What Are the Main Grades and Specifications of Phenolic Cotton Sheets

Understanding Grade Classifications

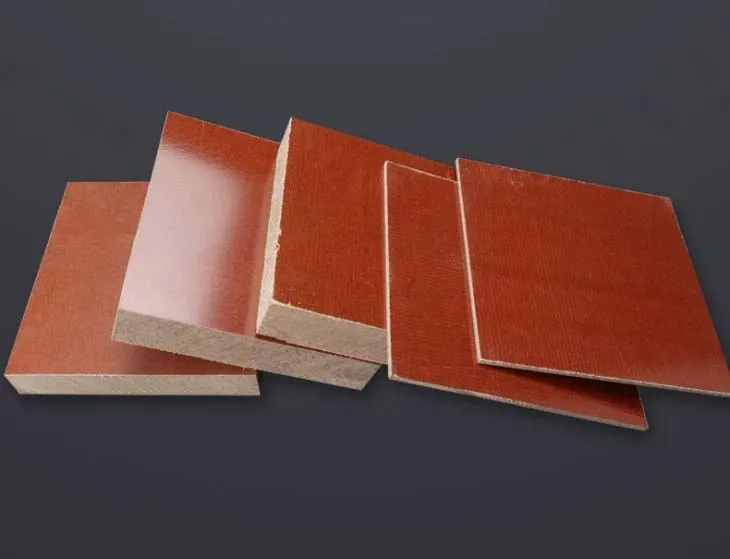

Phenolic cotton sheets are systematically classified into various grades, primarily distinguished by their composition and resultant properties. Among the most prevalent are Type A and Type B. Type A is specifically engineered to provide superior electrical insulation, making it indispensable in electrical components. Conversely, Type B is formulated to deliver enhanced mechanical strength and durability, suiting applications with significant structural demands. These clear-cut classifications serve as a critical guide for manufacturers and engineers, enabling them to make informed decisions and select the most appropriate material based on the specific mechanical, electrical, and thermal requirements of their projects, thereby ensuring optimal performance and safety.

Key Specifications and Their Significance

The performance and suitability of phenolic cotton sheets are defined by several essential specifications. Key among these are thickness, density, resin content, and surface finish. Thickness typically ranges from very thin 0.5mm sheets to robust 50mm plates, catering to diverse structural needs. Density, varying between 1.2 g/cm³ and 1.4 g/cm³, directly influences the material's weight and solidity. Perhaps most critically, the resin content, usually falling within 35% to 45%, is a primary determinant of the sheet's properties; a higher resin content generally improves electrical resistance and chemical stability but may impact mechanical toughness. These parameters collectively dictate the sheet's behavior in its final application.

Industry Standards and Certifications

To guarantee reliability and interoperability, phenolic cotton sheets are commonly manufactured in compliance with recognized international standards. These include established frameworks such as NEMA (National Electrical Manufacturers Association), IEC (International Electrotechnical Commission), and DIN (Deutsches Institut für Normung). Adherence to these standards ensures consistent quality, performance, and dimensional accuracy across different production batches and manufacturers. Furthermore, specific certifications like UL (Underwriters Laboratories) recognition for safety or RoHS (Restriction of Hazardous Substances) compliance for environmental safety are often imperative. These certifications are particularly crucial for applications in the electrical, electronics, and consumer goods sectors, where safety and regulatory adherence are paramount.

Matching Material Grades with Mechanical and Electrical Requirements

Assessing Mechanical Properties

When evaluating phenolic cotton sheets for mechanical applications, it is essential to analyze performance indicators such as tensile, flexural, and impact strength. Type B grades are particularly suited for components exposed to heavy loads or vibration, such as gears, bearings, and mechanical spacers. Additionally, checking the material’s wear resistance and dimensional stability ensures reliable operation in applications with continuous friction or tight tolerances, where precision and durability are critical to long-term performance.

Evaluating Electrical Insulation Needs

In electrical systems, phenolic cotton sheets must provide dependable insulation to prevent breakdowns or current leakage. Type A grades are engineered for superior dielectric strength, volume resistivity, and arc resistance, making them ideal for switchgear, transformers, and insulation barriers. When selecting a grade, consider the working voltage, frequency, and surrounding humidity or temperature conditions to maintain both safety and consistent performance over extended operational periods.

Balancing Thermal and Chemical Resistance

Different phenolic cotton sheet grades offer distinct thermal and chemical stability levels. Understanding the application’s temperature range and exposure to reactive substances helps ensure proper material selection. Some grades maintain mechanical integrity up to 150°C, while others resist oils, fuels, or solvents more effectively. Choosing the right balance between thermal endurance and chemical resistance helps extend service life and prevents material degradation under harsh industrial environments.

Procurement Standards and Quality Assurance for Industrial Applications

Establishing Supplier Qualifications

Choosing the right supplier is crucial to ensuring consistent quality and reliability of phenolic cotton sheets. Work with manufacturers that have proven expertise in industrial laminates and adhere to recognized quality standards such as ISO certifications. Evaluate their production capabilities, testing facilities, and supply stability. Requesting samples, test reports, and technical datasheets allows you to verify performance claims and confirm that the materials meet both mechanical and electrical requirements for your intended application.

Implementing Quality Control Measures

A strong quality assurance system ensures that all incoming phenolic cotton sheets align with your engineering and safety standards. This involves routine inspections of dimensions, surface finish, and density, along with laboratory testing for tensile strength, dielectric performance, and thermal stability. Establishing clear acceptance benchmarks and traceability documentation minimizes production risks. Consistent monitoring also helps detect deviations early, ensuring long-term reliability and uniformity across production batches.

Optimizing Cost and Performance

Achieving the right balance between material performance and budget is key in industrial procurement. While premium phenolic cotton sheets deliver enhanced durability and insulation, they must be evaluated against operational needs and lifecycle costs. Consider factors such as ease of machining, maintenance frequency, and part longevity when assessing value. Long-term contracts or bulk orders can help reduce per-unit costs, allowing you to secure high-quality materials without exceeding budget constraints.

Conclusion

Selecting the right grade of phenolic cotton sheet for industrial use demands a comprehensive approach. By understanding the various grades, specifications, and their applications, you can make informed decisions that align with your specific requirements. Remember to consider mechanical and electrical properties, thermal and chemical resistance, and quality assurance measures. Collaborating with reputable suppliers and implementing rigorous procurement standards will ensure you obtain high-quality materials that meet your industrial needs. Ultimately, the right choice will enhance your product's performance, durability, and cost-effectiveness.

FAQs

1. What are the main types of phenolic cotton sheets?

The main types are Type A, which has improved electrical properties, and Type B, which offers enhanced mechanical properties.

2. What are some common applications for phenolic cotton sheets?

Phenolic cotton sheets are used in various applications, including terminal boards, switches, bearings, gears, transformers, and industrial laminates.

3. What are the key features of phenolic cotton sheets?

Key features include excellent dielectric strength, good machinability, light weight, heat and wear resistance, chemical resistance, good mechanical strength, dimensional stability, and low moisture absorption.

Expert Phenolic Cotton Sheet Supplier: J&Q's Industrial Solutions

J&Q, with over 20 years of experience in producing and selling insulating sheets, offers expert guidance in selecting the right phenolic cotton sheet for your industrial needs. Our extensive knowledge of material properties and applications ensures you receive the optimal solution for your specific requirements. As a trusted manufacturer and supplier, we provide high-quality phenolic cotton sheets that meet rigorous industry standards. For personalized assistance and product information, contact our team at info@jhd-material.com.

References

Johnson, R. M. (2019). Industrial Applications of Phenolic Cotton Sheets: A Comprehensive Guide. Journal of Composite Materials, 53(12), 1589-1604.

Smith, A. L., & Brown, T. K. (2020). Mechanical Properties of Phenolic Cotton Laminates: Grade Selection Criteria. Materials Science and Engineering: A, 772, 138709.

Zhang, Y., et al. (2018). Electrical Insulation Performance of Phenolic Cotton Sheets in High-Voltage Applications. IEEE Transactions on Dielectrics and Electrical Insulation, 25(3), 1012-1020.

Miller, E. J. (2021). Quality Assurance Protocols for Industrial-Grade Phenolic Cotton Sheets. International Journal of Quality & Reliability Management, 38(4), 937-952.

Thompson, C. R., & Davis, L. M. (2017). Thermal and Chemical Resistance of Phenolic Cotton Laminates in Extreme Environments. Journal of Applied Polymer Science, 134(22), 44891.

Anderson, P. K., et al. (2022). Cost-Benefit Analysis of High-Performance Phenolic Cotton Sheets in Industrial Manufacturing. Journal of Industrial Engineering and Management, 15(2), 302-318.