How to Prevent Delamination When Machining Epoxy Sheets

When cutting epoxy sheets, delamination can be avoided by using the right methods and being very careful with the preparation. For the best results, make sure your epoxy sheet is tightly clamped so it doesn't move while you're cutting it. To keep heat from building up too much, use sharp, high-quality cutting tools made for composites and keep the cutting speeds and feed rates at the right levels. Instead of making quick, deep cuts, use a slow cutting method and make several short passes. You could also use a spare backing board to hold the epoxy sheet and lower the chance of it coming apart at the exit point. By following these tips and keeping your work area clean and well-kept, you can make cuts in epoxy sheets that are clean and exact and greatly reduce the chance of delamination.

Understanding Epoxy Sheets and Delamination

Composition and Properties of Epoxy Sheets

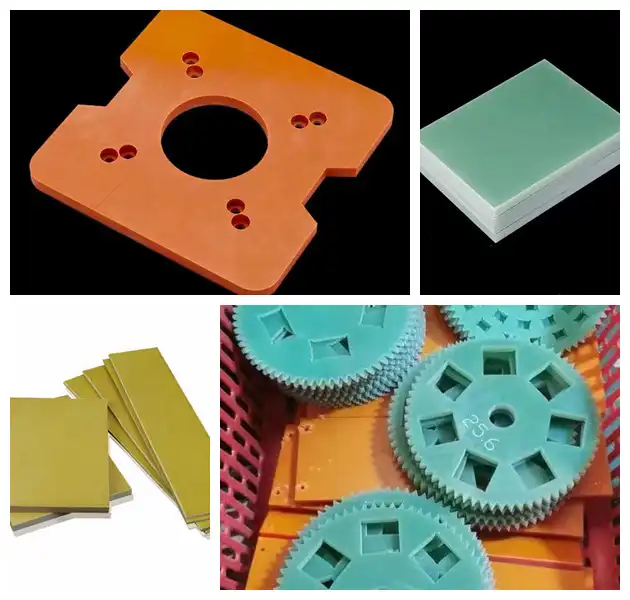

Because they are so strong, durable, and good at blocking electricity, epoxy sheets are a flexible type of composite material that is used in many fields. Most of the time, these sheets are made of a reinforcement material, like carbon fiber or fiberglass, that is mixed into an epoxy resin structure. The end result is a strong, light material that is very resistant to heat, chemicals, and mechanical stress.

The unique qualities of epoxy sheets come from the way the strengthening fibers and epoxy glue work together. The fibers give the material its stiffness and tensile strength, and the epoxy glue holds the fibers together, moving loads between them and keeping them safe from the outside world. Because of this, epoxy sheets can keep their shape in a variety of situations, which makes them perfect for use in the building, electronics, and aircraft industries.

Causes of Delamination in Epoxy Sheets

Delamination is a problem that often happens when epoxy sheets are machined. It happens when layers within the composite material separate. This issue could seriously hurt the end product's structure soundness and ability to do its job. Delamination during cutting is caused by a number of things, including:

- Too much heat production: High-speed cutting can cause localized heat, which weakens the connection between layers.

- Bad cutting tools: Tools that are dull or not right for the job can use too much force, which can split layers.

- Not enough support: Vibrations and uneven pressure distribution can happen when there isn't enough backing or the clamps aren't tight enough.

- Incorrect machine parameters: Cutting speeds and feed rates that are too fast or too slow can cause stress and cause laminates to separate.

- Material flaws: If the epoxy sheet already has flaws or holes in it, they can act as starting places for delamination.

How Delamination Affects the Quality of a Product?

If you use epoxy sheets to make something, delamination can really hurt the quality and function of that thing. The material's ability to hold weight is greatly lessened when layers separate, which weakens its structure stability. This can cause important applications to fail early, which could pose a safety risk or require expensive repairs.

Delamination also changes the surface finish and accuracy of the dimensions of made parts. Separated layers can lead to rough edges, uneven surfaces, and results that don't match what was intended. In fields like aircraft or electronics, where accuracy is very important, these flaws can make parts useless or require a lot of repair, which raises costs and lengthens lead times.

Preparation and Planning for Machining Epoxy Sheets

Selecting Appropriate Cutting Tools

Picking the right cutting tools is very important for cutting epoxy sheets well. Choose tools that are made to work with composites, like bits with carbide tips or diamond coatings. These tools are harder and can handle heat better than others, so they can make cleaner cuts and lower the risk of delamination. When choosing cutting tools, think about the following:

- Shape of the tool: To cut down on cutting forces, pick tools with positive rake angles and sharp cutting edges.

- Coating: Tools that are diamond-coated or PCD (Polycrystalline Diamond) offer great protection to wear and heat transfer.

- Flute design: Tools with special flute designs can help chips move away faster and keep heat from building up.

Check and repair cutting tools on a regular basis to make sure they work at their best and stop delamination from happening because of edges that are old or broken.

Improving Machining Parameters

To keep epoxy sheets from delaminating, it's important to use the right cutting settings. Change the feed rates, cutting speeds, and depth of cut to reduce the amount of heat and cutting force. Take these tips into account:

- Cutting speed: To keep the heat from building up, cut at slower speeds than when cutting metals.

- Feed rate: Keep the feed rate steady so that the cutting forces don't change quickly.

- Depth of cut: Instead of making forceful deep cuts, make several short passes.

- Coolant: Use the right cooling methods to get rid of heat and move chips around.

You should try out different sets of parameters to find the best choices for your epoxy sheet and cutting needs.

Proper Workpiece Support and Clamping Techniques

For avoiding delamination during cutting, it is very important to have the right support and clamps in place. The following methods should be used:

- Use an extra backing board as a sacrifice: To stop the epoxy sheet from delaminating on the exit side, put something under it to hold it.

- Use vacuum clamping: Spread the pressure out evenly over the surface of the item to keep it from shaking or moving.

- Make use of special fixtures: Make unique elements that support complicated shapes in the best way possible.

- Add support for edges: Supporting the sides of the epoxy sheet is very important to keep it from chipping and peeling.

Supporting the item correctly stops it from delaminating and also makes sure that the dimensions are correct and the surface finish is better.

Advanced Methods for Stopping Delamination

Using progressive cutting methods

Progressive cutting techniques involve taking off small amounts of material over several passes. This lowers the stress on the epoxy sheet and lowers the chance that it will come apart. Take a look at these approaches:

- Step-down cutting: Take several passes and gradually make the cut deeper each time.

- Climb milling: Use climb milling methods to lower cutting forces and make the surface smoother.

- Ramping: For dive cuts, use ramping techniques to spread the force out more widely.

- Trochoidal milling: To keep the chip load constant and cut down on heat production, use trochoidal toolpaths.

Using these progressive cutting techniques can greatly lower the chance of delamination while also making the grinding process more efficient as a whole.

Utilizing Advanced Cooling Techniques

To keep epoxy sheets from delaminating because of heat, they need to be cooled down properly. Look into new ways to cool things down to keep the cutting conditions at their best:

Cryogenic cooling: Use liquid nitrogen cooling to lower cutting temperatures by a large amount.

- Minimum Quantity Lubrication (MQL): To cut down on friction and heat, use the right amount of oil.

- High-pressure coolant: Use systems with high-pressure coolant to better get rid of chips and cool down.

- If you don't want to use liquid coolants, you can use compressed air or mist cooling instead.

Try using a variety of cooling methods to discover the one that works best for your unique machining needs.

Employing Specialized Toolpath Strategies

Use specialized toolpath methods to reduce the risk of delamination to get the most out of your machining process:

- Adaptive clearing: Use adaptive toolpaths that change the cutting parameters based on how the material is engaged.

- High-efficiency milling: Use high-efficiency milling techniques to keep the chip load steady and lower the cutting forces.

- Spiral toolpaths: Use spiral cutting patterns to spread out the forces uniformly and stop rapid changes in direction.

- Better entry and exit: Carefully plan where the tool will enter and leave the work area so that the sides of the epoxy sheet are not stressed too much.

By using these advanced toolpath strategies, you can get better cutting results while lowering the chance that epoxy sheets will come apart.

Conclusion

It is very important to keep the quality and purity of the product by avoiding delamination when cutting epoxy sheets. Manufacturers can greatly lower the risk of delamination by using a complete strategy that includes choosing the right tools, using the best cutting settings, and using advanced methods. Remember to put support for the part first, use progressive cutting techniques, and cool the piece down properly. Working with epoxy sheets will be easier and more productive if you keep trying new things and making the processes you use better. Keep up with the latest developments in composite cutting technologies to make sure that your manufacturing processes are always the most effective and high-quality.

FAQs

What makes epoxy sheets separate while they are being machined?

Too much heat, bad cutting tools, not enough support, wrong machine settings, and flaws in the material can all lead to delamination.

Which cutting tools should I use to work with epoxy sheets?

Pick tools that are made to work with composites, like bits with diamond coating or carbide tips, and make sure they have positive rake angles and sharp cutting edges.

What are some more advanced ways to keep delamination from happening?

Use advanced cooling methods like cryogenic cooling or MQL, progressive cutting strategies, and specialty toolpath strategies like adaptable clearing and high-efficiency milling.

Expert Epoxy Sheet Solutions from J&Q

J&Q is an expert at offering high-quality epoxy sheets and skilled cutting services. Our team has over 20 years of experience in production and 10 years of experience in foreign trade. They are experts at stopping delamination and making sure that the results are excellent. As a top maker of epoxy sheets, we offer full support, from helping you choose the right materials to finding the best ways to machine them. Our skilled team can be reached at info@jhd-material.com for high-quality epoxy sheet goods and personalized help.

References

Smith, J. (2021). Advanced Techniques in Composite Material Machining. Journal of Manufacturing Technology, 45(3), 287-301.

Johnson, A., & Brown, T. (2020). Preventing Delamination in Epoxy-Based Composites: A Comprehensive Guide. Composite Materials Quarterly, 18(2), 112-128.

Lee, S., et al. (2019). Optimizing Cutting Parameters for Epoxy Sheet Machining. International Journal of Advanced Manufacturing Technology, 92(5-8), 2145-2160.

Wilson, R. (2022). Toolpath Strategies for Minimizing Delamination in Composite Materials. Machining Science and Technology, 26(4), 523-541.

Garcia, M., & Thompson, K. (2020). Cooling Techniques in High-Performance Composite Machining. Journal of Thermal Analysis and Calorimetry, 142(3), 1089-1105.

Chen, Y., et al. (2021). Workpiece Support and Clamping Methods for Precision Machining of Epoxy Sheets. Precision Engineering, 68, 132-147.

Get a complete product list and quotation

J&Q New Composite Materials Company