Understanding G10 Sheets: Composition and Properties

The Unique Composition of G10 Sheets

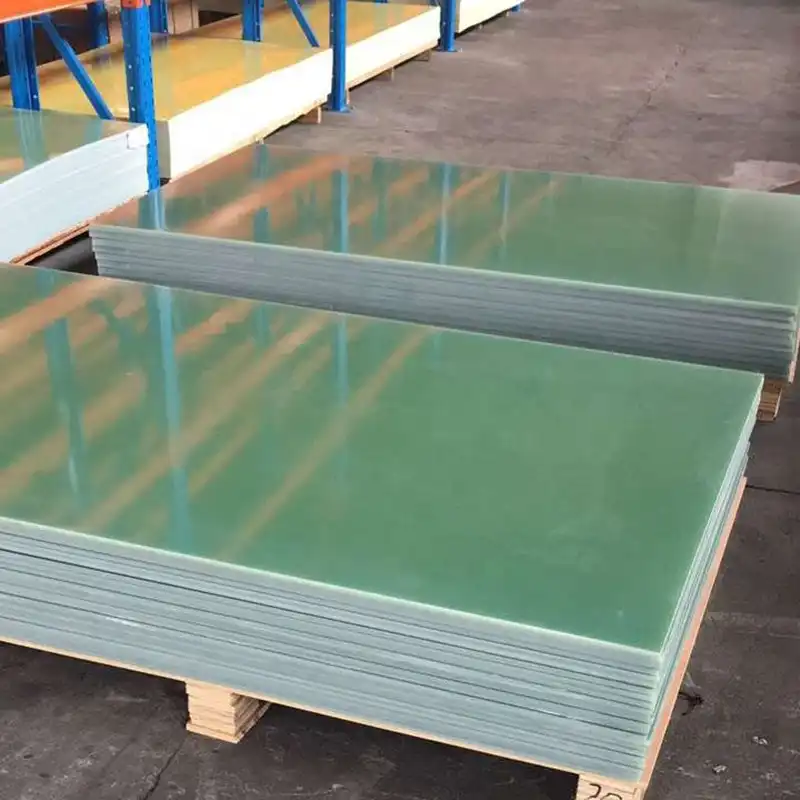

G10 sheets are high-performance composite materials crafted from a meticulous blend of epoxy resin and woven glass fabric. This synergistic combination results in a product that boasts exceptional mechanical strength, electrical insulation properties, and dimensional stability. The epoxy resin acts as a binding agent, while the glass fabric reinforces the structure, creating a robust and versatile material suitable for diverse applications.

Key Properties of G10 Sheets

The remarkable properties of G10 sheets make them indispensable in various industries. These sheets exhibit outstanding electrical insulation capabilities, making them ideal for use in electronic components and circuit boards. Their high mechanical strength allows them to withstand significant stress and strain without compromising structural integrity. G10 sheets also demonstrate excellent resistance to moisture absorption, chemicals, and heat, contributing to their longevity in challenging environments.

Applications Across Industries

The versatility of G10 sheets is evident in their widespread use across multiple sectors. In the aerospace industry, they are utilized for structural components and electrical insulation. The automotive sector employs G10 sheets in underhood applications and electrical systems. Marine environments benefit from their corrosion resistance in boat construction and underwater equipment. Additionally, G10 sheets find applications in medical devices, sporting goods, and industrial machinery, showcasing their adaptability to diverse requirements.

Essential Maintenance Practices for G10 Sheets

Regular Cleaning and Inspection Routines

Maintaining the pristine condition of G10 sheets requires a consistent cleaning regimen. Use a soft, lint-free cloth dampened with a mild detergent solution to gently remove dust, dirt, and other contaminants from the surface. Avoid abrasive cleaners or tools that could scratch or damage the material. After cleaning, thoroughly dry the sheets to prevent moisture accumulation. Implement a regular inspection schedule to identify any signs of wear, discoloration, or damage. Early detection of issues allows for prompt intervention, potentially preventing more significant problems down the line.

Proper Handling and Storage Techniques

Correct handling and storage play a pivotal role in preserving the integrity of G10 sheets. When moving or transporting these materials, use appropriate lifting equipment to avoid bending or flexing the sheets excessively. Store G10 sheets in a cool, dry environment away from direct sunlight and sources of heat. Maintain proper ventilation in the storage area to prevent moisture buildup. Stack the sheets horizontally on a flat, level surface, using spacers between each sheet to allow air circulation and prevent warping. Avoid placing heavy objects on top of the stack to maintain the sheets' flatness and structural integrity.

Protecting Against Environmental Factors

G10 sheets, while resilient, can be affected by prolonged exposure to harsh environmental conditions. Shield the sheets from extreme temperatures, as excessive heat or cold can lead to thermal stress and potential deformation. Minimize exposure to ultraviolet (UV) radiation, which can cause gradual degradation of the epoxy resin. In environments with high humidity or potential for chemical exposure, consider applying specialized protective coatings to enhance the sheets' resistance to moisture and corrosive substances. Implementing these protective measures can significantly extend the lifespan and maintain the performance of G10 sheets in challenging applications.

Advanced Techniques for Extending G10 Sheet Lifespan

Implementing Preventive Maintenance Strategies

Proactive maintenance is key to maximizing the longevity of G10 sheets. Develop a comprehensive preventive maintenance plan that includes regular assessments of the sheets' condition, performance, and surrounding environment. Utilize non-destructive testing methods, such as ultrasonic inspection or thermography, to detect internal defects or changes in material properties that may not be visible to the naked eye. Implement a system for tracking the usage history and environmental exposure of each G10 sheet, allowing for more accurate predictions of potential wear and replacement needs. By anticipating and addressing potential issues before they escalate, you can significantly extend the operational life of G10 sheets in your applications.

Optimizing Installation and Usage Practices

The manner in which G10 sheets are installed and utilized can greatly impact their lifespan. Ensure that the sheets are properly sized and cut for their intended application, minimizing stress points and potential areas of weakness. Use appropriate fastening methods and materials that are compatible with G10 sheets, avoiding over-tightening or creating areas of concentrated stress. When designing systems or components using G10 sheets, consider the material's thermal expansion properties and allow for adequate flexibility in the installation. Regularly review and optimize the usage conditions of G10 sheets, ensuring they are not subjected to loads or environmental factors beyond their specified capabilities.

Innovative Surface Treatments and Coatings

Advancing technology has led to the development of innovative surface treatments and coatings that can enhance the durability and performance of G10 sheets. Explore the application of nano-coatings that provide superior resistance to moisture, chemicals, and abrasion while maintaining the sheet's electrical properties. Consider plasma treatment techniques that can modify the surface characteristics of G10 sheets, improving their adhesion properties for specific applications. Investigate the use of specialized edge sealants to protect against moisture ingress and delamination in critical areas. By incorporating these cutting-edge treatments, you can create a protective barrier that significantly extends the functional lifespan of G10 sheets in demanding environments.

Conclusion

Maintaining and extending the lifespan of G10 sheets is a multifaceted process that requires attention to detail and proactive measures. By understanding the unique properties of these versatile materials and implementing comprehensive maintenance strategies, you can ensure optimal performance and longevity. Regular cleaning, proper handling, and protection against environmental factors form the foundation of effective G10 sheet care. Advanced techniques, including preventive maintenance, optimized installation practices, and innovative surface treatments, further enhance their durability. By integrating these approaches, industries can maximize the value and reliability of G10 sheets in their applications, leading to improved efficiency and cost-effectiveness in the long run.

Contact Us

For more information about our G10 sheets and expert guidance on maintenance practices, please contact us at info@jhd-material.com. Our team of specialists is ready to assist you in optimizing the performance and lifespan of your G10 sheet applications.