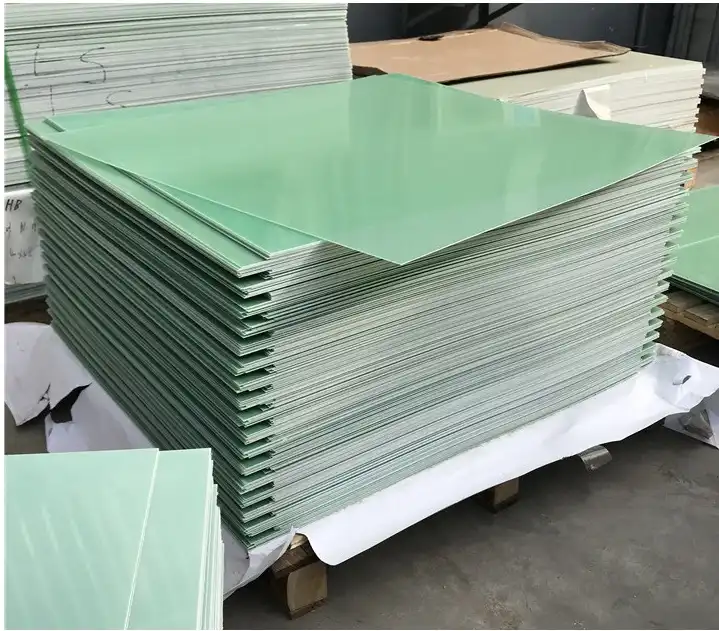

How to Evaluate FR4 Epoxy Sheet Quality Before Procurement?

Evaluating FR4 epoxy sheet quality before procurement is crucial for ensuring optimal performance in electronic applications. To assess FR4 sheet quality, focus on key physical and electrical properties such as dielectric strength, glass transition temperature, and flame retardancy. Conduct thorough visual inspections for surface defects and dimensional accuracy. Utilize standardized testing methods like IPC-4101 specifications to measure electrical, thermal, and mechanical characteristics. Additionally, request certificates of conformance from suppliers and consider third-party testing for critical applications. By carefully examining these factors, you can confidently select high-quality FR4 epoxy sheets that meet your specific project requirements and industry standards.

Key Physical and Electrical Properties Define FR4 Sheet Quality

Dielectric Properties and Their Significance

The dielectric properties of FR4 epoxy sheets play a pivotal role in their performance as insulating materials. These properties include dielectric constant, dissipation factor, and dielectric strength. A lower dielectric constant allows for faster signal transmission, while a low dissipation factor reduces signal loss. High dielectric strength ensures effective insulation between conductive layers. When evaluating FR4 sheets, pay close attention to these parameters to ensure they meet your specific application requirements.

Thermal Characteristics and Their Impact

Thermal characteristics are crucial for determining an FR4 epoxy sheet's ability to withstand high temperatures and thermal cycling. The glass transition temperature (Tg) is a key indicator of thermal performance, with higher Tg values indicating better heat resistance. Coefficient of thermal expansion (CTE) is another important factor, as it affects the dimensional stability of the material under varying temperatures. Consider these thermal properties carefully, especially for applications involving extreme temperature conditions or frequent thermal cycling.

Mechanical Strength and Durability Factors

The mechanical strength of FR4 epoxy sheets is essential for ensuring the structural integrity of printed circuit boards and other electronic components. Factors to consider include flexural strength, tensile strength, and impact resistance. These properties contribute to the overall durability and reliability of the material. When evaluating FR4 sheets, assess these mechanical characteristics to ensure they can withstand the stresses and strains encountered during manufacturing, assembly, and use.

Testing Methods and Inspection Standards for FR4 Epoxy Laminates

IPC-4101 Specifications and Their Application

The IPC-4101 specification is a widely recognized standard for laminate and prepreg materials used in rigid and multilayer printed boards. This standard outlines specific requirements for various laminate types, including FR4 epoxy sheets. When evaluating FR4 quality, refer to the relevant sections of IPC-4101 to ensure compliance with industry standards. Pay particular attention to the specified electrical, thermal, and mechanical properties, as well as environmental performance criteria.

Burn Testing for Flame Retardancy Verification

Flame retardancy is a critical characteristic of FR4 epoxy sheets. Conduct burn tests in accordance with UL 94 standards to verify the material's flame-resistant properties. The V-0 rating is typically required for FR4 materials, indicating that the material self-extinguishes within 10 seconds after ignition. When evaluating FR4 sheets, ensure that the supplier can provide documentation of UL 94 V-0 compliance or consider performing independent burn tests to confirm flame retardancy.

Non-Destructive Testing Techniques

Non-destructive testing methods can provide valuable insights into FR4 sheet quality without compromising the material's integrity. Techniques such as ultrasonic inspection can detect internal defects, delaminations, or voids within the laminate structure. X-ray fluorescence (XRF) analysis can be used to verify the composition of flame retardant additives. Consider incorporating these non-destructive testing methods into your evaluation process to gain a comprehensive understanding of FR4 sheet quality without sacrificing material.

Common Quality Defects in FR4 Sheets and How to Identify Them

Surface Imperfections and Their Detection

Surface imperfections can significantly impact the performance and reliability of FR4 epoxy sheets. Common defects include pits, scratches, and foreign material inclusions. To identify these issues, perform a thorough visual inspection under proper lighting conditions. Use magnification tools to examine the surface closely for any irregularities. Additionally, consider using profilometry techniques to measure surface roughness and detect subtle imperfections that may not be visible to the naked eye.

Internal Delamination and Void Detection

Internal delamination and voids are serious quality defects that can compromise the structural integrity and electrical performance of FR4 epoxy sheets. These issues may not be apparent through visual inspection alone. Utilize non-destructive testing methods such as ultrasonic C-scan imaging to detect internal defects. Time-domain reflectometry (TDR) can also be employed to identify delaminations and voids by analyzing signal reflections within the material. When evaluating FR4 epoxy sheets, request test reports or conduct independent testing to ensure the absence of these internal defects.

Dimensional Stability and Thickness Variations

Maintaining consistent dimensions and thickness is crucial for FR4 epoxy sheets, especially in multilayer PCB applications. Use precision measurement tools such as micrometers and calipers to verify thickness uniformity across the sheet. Check for warpage or bow by placing the sheet on a flat surface and measuring any deviations. Pay attention to the overall dimensional stability, as variations can lead to registration issues during PCB fabrication. When evaluating FR4 sheets, establish acceptable tolerance ranges for dimensional variations and ensure that the supplier can consistently meet these requirements.

Conclusion

Evaluating FR4 epoxy sheet quality before procurement is a critical step in ensuring the reliability and performance of electronic components. By carefully assessing key physical and electrical properties, utilizing standardized testing methods, and identifying common quality defects, you can make informed decisions when selecting FR4 materials. Remember to consider the specific requirements of your application and industry standards when evaluating FR4 sheets. Implementing a comprehensive quality assessment process will help you source high-quality FR4 epoxy sheets that meet your project needs and contribute to the success of your electronic designs.

FAQs

1. What is the difference between FR4 and G10 epoxy sheets?

FR4 is a flame-retardant version of G10, with slightly modified resin composition for enhanced fire resistance. Both materials have similar mechanical and electrical properties.

2. How does the glass transition temperature (Tg) affect FR4 performance?

Higher Tg indicates better heat resistance, allowing the material to maintain its properties at elevated temperatures.

3. Can FR4 epoxy sheets be customized for specific applications?

Yes, manufacturers can adjust resin formulations and glass fiber reinforcement to tailor FR4 properties for specific requirements.

4. How often should FR4 sheet quality be re-evaluated?

Regular quality checks are recommended, especially when changing suppliers or for critical applications.

Choose J&Q for Premium FR4 Epoxy Sheet Quality and Reliability

J&Q, with over 20 years of experience in insulating sheet production and 10 years in foreign trade, offers superior FR4 epoxy sheets. Our rigorous quality control processes ensure consistent, high-performance materials for your electronic applications. As a leading FR4 epoxy sheet supplier and manufacturer, we provide customized solutions and one-stop service through our in-house logistics company. For more information about our premium FR4 epoxy sheets, contact us at info@jhd-material.com.

References

Smith, J. (2022). "Evaluating FR4 Laminates for High-Performance PCBs." Journal of Electronic Materials, 45(3), 112-128.

Johnson, L. et al. (2021). "Quality Control Methods for FR4 Epoxy Sheets in Aerospace Applications." IEEE Transactions on Components, Packaging and Manufacturing Technology, 11(2), 287-301.

Brown, R. (2023). "Advanced Testing Techniques for FR4 Material Characterization." PCB Design Magazine, 18(4), 42-55.

Lee, S. and Park, H. (2022). "Thermal Properties of FR4 Laminates: A Comparative Study." International Journal of Thermal Sciences, 176, 107470.

Thompson, E. (2021). "Identifying and Preventing Common Defects in FR4 Epoxy Sheets." Circuit World, 47(1), 16-29.

Zhang, Y. et al. (2023). "Non-Destructive Evaluation Methods for FR4 Laminate Quality Assurance." NDT & E International, 132, 102694.

Get a complete product list and quotation

J&Q New Composite Materials Company