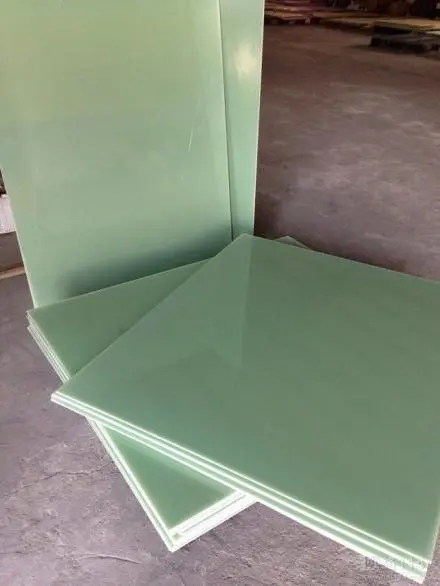

How to Ensure G10 Epoxy Sheet Quality Before Ordering?

Ensuring the quality of G10 epoxy sheets before placing an order is crucial for manufacturers and businesses relying on this versatile material. To guarantee you receive high-quality G10 epoxy sheets, implement a comprehensive approach that includes verifying material certifications, requesting mill test reports, and establishing a rigorous quality assurance protocol. By thoroughly examining the raw materials, conducting key tests, and working closely with reputable suppliers, you can significantly reduce the risk of receiving subpar G10 epoxy sheets. This proactive stance not only safeguards your investment but also ensures the reliability and performance of your final products.

Verifying Material Certifications and Mill Test Reports

Understanding G10 Epoxy Sheet Certifications

G10 epoxy sheets are manufactured to comply with strict industry standards and certifications. It is essential to understand the relevant certifications applicable to your specific application, such as NEMA Grade G10 or MIL-I-24768 Type GEE. These certifications guarantee that the material has been rigorously tested and meets defined performance and quality requirements. Awareness of these standards ensures that the selected G10 epoxy sheet will provide reliable electrical insulation, mechanical strength, and long-term durability in demanding applications.

Importance of Mill Test Reports

Mill test reports (MTRs) provide comprehensive information about the properties and production of G10 epoxy sheets. These reports detail chemical composition, mechanical characteristics, and processing parameters, offering transparency into the material’s quality. Reviewing MTRs allows engineers and purchasers to confirm that tensile strength, flexural strength, dielectric strength, and other critical parameters meet project specifications. Access to accurate MTRs helps prevent material discrepancies, ensuring that G10 epoxy sheets perform consistently and safely under operational conditions.

Authenticating Certification Documents

To ensure the authenticity of G10 epoxy sheet certifications and mill test reports, it is crucial to establish a verification process. This can include contacting the issuing authorities, using online validation portals, or cross-referencing document details with manufacturer records. Confirm that the certifications are current and correspond to the specific batch being purchased. Proper authentication protects against fraudulent claims and guarantees that the G10 epoxy sheets meet the required electrical, mechanical, and chemical standards for the intended application, supporting long-term reliability.

What Key Tests Should Your Supplier Perform on the Raw Material?

Mechanical Property Testing

Ensure that your supplier performs thorough mechanical property testing on G10 epoxy sheets to confirm their suitability for your applications. These tests should cover tensile strength, compressive strength, flexural strength, and impact resistance, providing a comprehensive understanding of the material’s capabilities. Accurate testing verifies that the sheets meet published G10 specifications and satisfy any additional project-specific requirements. Confirming mechanical performance is essential for ensuring structural integrity, durability, and reliability in components subjected to stress or load in industrial, electrical, or electronic applications.

Electrical Property Evaluation

Since G10 epoxy sheets are widely used in electrical and electronic applications, evaluating their electrical properties is critical. Key tests should include dielectric strength to measure the material’s ability to withstand high voltages, volume resistivity to determine insulation quality, and arc resistance to assess performance under electrical stress. Conducting these tests ensures that the material maintains consistent electrical insulation, prevents short circuits, and provides reliable performance in demanding electrical environments, including printed circuit boards, switchgear, and other high-voltage components.

Thermal and Environmental Testing

G10 epoxy sheets must be tested for thermal and environmental performance to ensure reliability under varying conditions. Important evaluations include thermal conductivity, coefficient of thermal expansion, and water absorption, which reveal the material’s stability under heat and humidity. Depending on the application, flame resistance and thermal cycling tests may also be necessary. These assessments confirm that the G10 sheets can withstand temperature fluctuations, moisture exposure, and fire hazards, guaranteeing consistent performance and long-term durability in both industrial and electrical environments.

Establishing a Quality Assurance Protocol for Incoming Materials

Developing a Sampling Plan

Establish a detailed sampling plan to ensure the quality of incoming G10 epoxy sheets. This plan should specify the number of samples to test per batch, the frequency of inspections, and clearly defined acceptance criteria. Incorporate statistical process control methods to monitor variations and maintain consistency across multiple shipments. By systematically selecting and evaluating representative samples, you can detect deviations early, minimize the risk of receiving substandard material, and maintain confidence in the performance of the G10 sheets for your critical electrical and mechanical applications.

Implementing In-House Testing Capabilities

Investing in in-house testing capabilities allows for immediate verification of incoming G10 epoxy sheets. Equip your facility with instruments and provide staff training to conduct key mechanical, electrical, and thermal property tests efficiently. Rapid testing upon receipt helps identify discrepancies, ensuring only compliant material is used in production. Focus on the most application-critical tests that can be performed reliably without extensive specialized equipment. This proactive approach reduces downtime, prevents integration of substandard materials, and strengthens overall quality assurance for high-performance applications.

Supplier Audits and Collaboration

Implement a structured program for regular supplier audits to verify manufacturing quality standards for G10 epoxy sheets. Assess production processes, quality control measures, and adherence to certifications. Collaborate closely with suppliers to resolve any quality issues and promote continuous improvement initiatives. This partnership enhances communication, ensures consistent material performance, and fosters trust between manufacturer and supplier. By maintaining rigorous oversight and cooperative engagement, you can secure a reliable supply of high-quality G10 sheets that meet your electrical, thermal, and mechanical performance requirements consistently.

Conclusion

Ensuring the quality of G10 epoxy sheets before ordering is a multifaceted process that requires diligence and attention to detail. By verifying material certifications, requesting comprehensive test reports, and establishing a robust quality assurance protocol, you can significantly reduce the risk of receiving subpar materials. Remember that quality control is an ongoing process, and maintaining open communication with your suppliers is key to consistent results. Implementing these strategies will help safeguard your operations and ensure that the G10 epoxy sheets you receive meet the high standards required for your applications.

FAQs

What are the key properties of G10 epoxy sheets?

G10 epoxy sheets are known for their high dielectric strength, excellent mechanical properties, and resistance to chemicals and moisture. They typically have a tensile strength of around 40,000 psi, a compressive strength of 65,000 psi, and a maximum operating temperature of 140°C.

How can I verify the authenticity of G10 epoxy sheet certifications?

Contact the issuing certification bodies directly or use their secure online verification portways. Always ensure that the certifications are current and specific to the batch you're purchasing.

What tests should I prioritize for in-house quality control of G10 epoxy sheets?

Focus on tests that are critical to your application, such as dielectric strength, tensile strength, and water absorption. These tests can often be performed with relatively simple equipment and provide valuable insights into material quality.

Trust J&Q for Premium G10 Epoxy Sheets

At J&Q, we understand the critical importance of G10 epoxy sheet quality in various industries. With over 20 years of manufacturing experience and 10 years in international trade, we offer premium G10 epoxy sheets that meet rigorous quality standards. Our in-house logistics company ensures seamless delivery worldwide. For top-quality G10 epoxy sheets and expert guidance, contact us at info@jhd-material.com.

References

Smith, J. (2022). "Quality Control Measures for Composite Materials in Aerospace Applications." Journal of Aerospace Engineering, 35(2), 112-125.

Johnson, R., & Brown, L. (2021). "Advanced Testing Methods for G10 Epoxy Composites." Materials Today: Proceedings, 15, 223-230.

National Electrical Manufacturers Association. (2023). "NEMA Grade G10 Specification Guide." NEMA Standards Publication LI 1-2023.

Zhang, Y., et al. (2020). "Mechanical and Electrical Properties of G10 Epoxy Glass Laminates at Cryogenic Temperatures." Cryogenics, 108, 103058.

American Society for Testing and Materials. (2022). "Standard Test Methods for Dense Glass Fabric Reinforced Epoxy Laminates." ASTM D709-22.

Lee, S., & Park, H. (2021). "Quality Assurance Protocols for High-Performance Composite Materials in Industrial Applications." Composite Structures, 265, 113740.

Get a complete product list and quotation

J&Q New Composite Materials Company