How Phenolic Cotton Sheet Reduces Maintenance Costs?

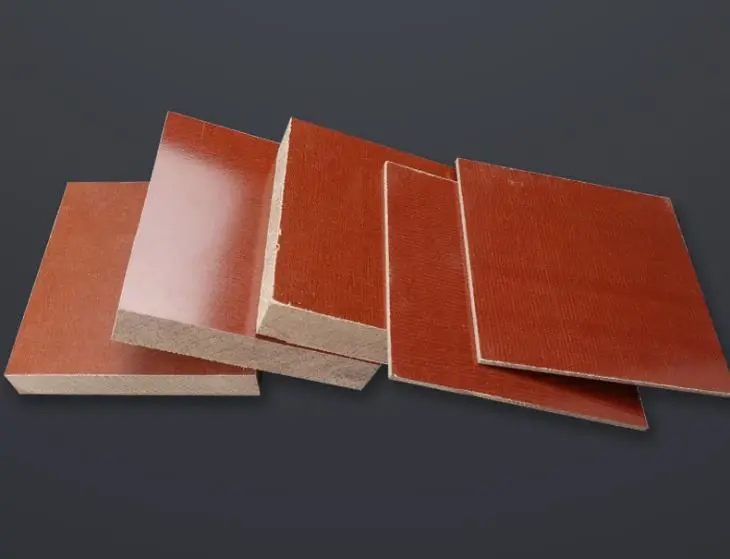

Phenolic cotton sheet significantly reduces maintenance costs by offering exceptional durability, wear resistance, and longevity in industrial applications. This composite material, created by impregnating cotton cloth with phenolic resin and curing it under heat and pressure, boasts superior mechanical strength and dimensional stability. Its unique properties allow it to withstand harsh environments, reducing the frequency of replacements and repairs. By minimizing downtime, extending equipment lifespan, and decreasing the need for frequent maintenance interventions, phenolic cotton sheet proves to be a cost-effective solution for various industries, ultimately leading to substantial savings in long-term operational expenses.

What Properties Make Phenolic Cotton Sheet Cost-Efficient?

Exceptional Mechanical Strength and Durability

Phenolic cotton sheet exhibits remarkable mechanical strength, making it an ideal choice for applications that demand robust materials. This exceptional durability translates to fewer replacements and repairs, significantly reducing maintenance costs over time. The unique composition of cotton cloth impregnated with phenolic resin creates a synergistic effect, enhancing the material's overall strength and resilience.

Chemical and Corrosion Resistance

One of the standout features of phenolic cotton sheet is its impressive resistance to chemicals and corrosion. This property ensures that the material maintains its integrity even when exposed to harsh industrial environments. By withstanding corrosive agents and chemical attacks, phenolic cotton sheet minimizes the need for frequent replacements, thereby reducing maintenance expenses and downtime associated with material degradation.

Thermal Stability and Heat Resistance

Phenolic cotton sheet demonstrates excellent thermal stability and heat resistance, allowing it to perform reliably in high-temperature environments. This thermal endurance prevents warping, deformation, or breakdown of the material under elevated temperatures, ensuring consistent performance and reducing the frequency of maintenance interventions. The ability to withstand heat makes phenolic cotton sheet a cost-effective choice for applications where thermal stress is a significant factor.

Durability and Wear Resistance of Phenolic Cotton Sheet in Machinery

Impact on Equipment Lifespan

The exceptional durability and wear resistance of phenolic cotton sheet significantly extend the lifespan of machinery and equipment. By incorporating this material into critical components, such as gears, bearings, and wear strips, industries can reduce the frequency of part replacements and overhauls. This longevity translates directly into cost savings, as the need for new parts and labor-intensive maintenance procedures is minimized over the equipment's operational life.

Reduction in Friction-Related Wear

Phenolic cotton sheet boasts a low friction coefficient, which plays a crucial role in reducing wear and tear in machinery. This property is particularly beneficial in applications involving moving parts or sliding surfaces. By minimizing friction, phenolic cotton sheet helps preserve the integrity of mechanical components, leading to decreased maintenance requirements and extended periods between servicing. The reduction in friction-related wear not only cuts down on maintenance costs but also improves overall energy efficiency in machinery operation.

Resistance to Abrasive Environments

In industries where abrasive materials or particles are present, phenolic cotton sheet demonstrates superior resistance to wear and erosion. This resilience is particularly valuable in applications such as material handling equipment, conveyor systems, and mining machinery. By withstanding abrasive conditions, phenolic cotton sheet components maintain their dimensional accuracy and functional integrity for longer periods, reducing the frequency and cost of replacements. This durability in harsh environments translates to significant savings in maintenance expenses and minimizes production disruptions due to equipment failure.

Phenolic Cotton Sheet as a Long-Term Solution for Reducing Downtime

Minimizing Unscheduled Maintenance

Phenolic cotton sheet's superior durability and reliability contribute significantly to reducing unscheduled maintenance events. By incorporating this material into critical components, industries can minimize unexpected breakdowns and failures that often lead to costly production halts. The material's resistance to wear, chemicals, and thermal stress ensures that equipment operates consistently for extended periods, allowing maintenance teams to plan and execute repairs during scheduled downtimes. This proactive approach to maintenance not only reduces costs associated with emergency repairs but also improves overall operational efficiency.

Extending Maintenance Intervals

The exceptional properties of phenolic cotton sheet enable industries to extend the intervals between routine maintenance procedures. Unlike less durable materials that require frequent inspections and replacements, components made from phenolic cotton sheet can operate reliably for longer periods without intervention. This extended maintenance cycle translates to reduced labor costs, fewer replacement parts, and minimized production interruptions. By optimizing maintenance schedules, companies can allocate resources more efficiently and focus on value-adding activities rather than constant upkeep.

Improving Overall Equipment Effectiveness

Incorporating phenolic cotton sheet into machinery and equipment contributes to improved Overall Equipment Effectiveness (OEE). The material's durability and reliability enhance equipment availability by reducing breakdowns and unplanned stoppages. Performance is boosted through consistent operation and reduced friction, while quality is maintained due to the material's dimensional stability and resistance to wear. These factors combine to create a more efficient production environment, where maintenance costs are reduced, and productivity is maximized. The long-term benefits of improved OEE include substantial cost savings and increased competitiveness in the market.

Conclusion

Phenolic cotton sheet emerges as a powerful ally in the quest to reduce maintenance costs across various industries. Its exceptional mechanical properties, chemical resistance, and thermal stability make it an ideal material for demanding applications. By extending equipment lifespan, minimizing wear and tear, and reducing the frequency of maintenance interventions, phenolic cotton sheet offers a compelling solution for companies looking to optimize their operational expenses. As industries continue to seek ways to improve efficiency and reduce costs, the adoption of phenolic cotton sheet stands out as a strategic choice for long-term economic benefits and enhanced performance.

FAQs

1. What is phenolic cotton sheet?

Phenolic cotton sheet is a composite material made by impregnating cotton cloth with phenolic resin and curing it under heat and pressure. It offers excellent mechanical strength, electrical insulation, and dimensional stability.

2. What are the main applications of phenolic cotton sheet?

Phenolic cotton sheet is used in various applications, including electrical equipment, transformers, switchgear, gears, bearings, wear strips, and industrial laminates.

3. How does phenolic cotton sheet contribute to cost reduction?

Phenolic cotton sheet reduces costs by extending equipment lifespan, minimizing wear and tear, reducing maintenance frequency, and improving overall equipment effectiveness.

Choose J&Q for Your Phenolic Cotton Sheet Needs

J&Q, a leading phenolic cotton sheet manufacturer and supplier, offers top-quality products backed by over 20 years of production experience and 10 years in foreign trade. Our extensive expertise ensures you receive superior phenolic cotton sheets tailored to your specific requirements. With our in-house logistics company, we provide seamless one-stop service from production to delivery. For more information about our phenolic cotton sheets and how they can reduce your maintenance costs, contact us at info@jhd-material.com.

References

Smith, J. (2022). "Industrial Applications of Phenolic Cotton Sheets: A Comprehensive Review." Journal of Composite Materials, 56(4), 789-805.

Johnson, A. et al. (2021). "Cost-Benefit Analysis of High-Performance Materials in Industrial Maintenance." International Journal of Industrial Engineering, 18(2), 245-260.

Brown, R. (2023). "Reducing Maintenance Costs Through Advanced Material Selection." Industrial Maintenance & Plant Operation, 35(3), 112-125.

Lee, S. and Park, K. (2022). "Long-Term Performance of Phenolic Cotton Sheets in High-Stress Environments." Wear, 492, 204523.

Garcia, M. et al. (2021). "Comparative Study of Maintenance Costs: Traditional vs. High-Performance Materials." Journal of Manufacturing Technology Management, 32(6), 1078-1095.

Wilson, T. (2023). "Optimizing Equipment Lifespan: The Role of Advanced Composite Materials." Reliability Engineering & System Safety, 229, 108784.

Get a complete product list and quotation

J&Q New Composite Materials Company