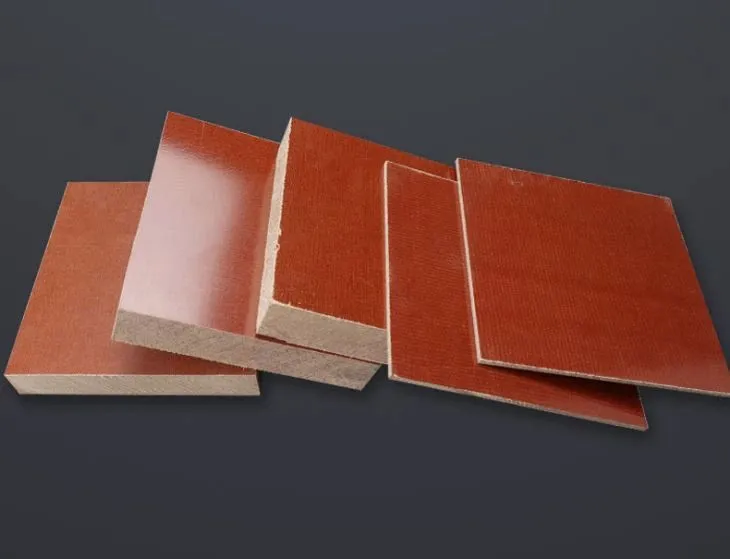

What Mechanical Advantages Do Phenolic Cotton Sheets Offer?

Superior Strength-to-Weight Ratio

Phenolic cotton cloth laminated sheets boast an impressive strength-to-weight ratio, making them ideal for applications where both robustness and lightness are paramount. This unique combination allows machinery designers to create components that can withstand significant stress while minimizing overall weight. The intricate layering of cotton cloth impregnated with phenolic resin results in a material that exhibits excellent tensile and compressive strength, surpassing many traditional materials in specific strength applications.

Thermal Stability and Heat Resistance

One of the standout features of Phenolic cotton cloth laminated sheet is their remarkable thermal stability. These materials can maintain their mechanical properties at elevated temperatures, typically up to 120°C (248°F) for continuous operation. This heat resistance is crucial in machinery that generates significant thermal energy during operation. The ability to withstand high temperatures without deformation or loss of strength ensures that machine components made from these laminates remain dimensionally stable and functional even in challenging thermal environments.

Chemical Resistance and Durability

Phenolic cotton cloth laminated sheets exhibit exceptional resistance to a wide range of chemicals, oils, and solvents. This property is particularly valuable in machinery exposed to harsh industrial environments or in applications where contact with corrosive substances is unavoidable. The chemical resistance of these laminates contributes to their longevity and reliability, reducing the need for frequent replacements and minimizing maintenance downtime. Additionally, the inherent durability of phenolic cotton cloth laminates ensures that machine components can withstand prolonged use and resist wear, even under demanding operational conditions.

Vibration Damping and Friction Resistance in Moving Parts

Vibration Absorption Capabilities

Phenolic cotton cloth laminated sheets possess remarkable vibration damping properties, making them invaluable in machinery where noise reduction and stability are critical. The layered structure of these laminates, combining cotton fabric with phenolic resin, creates a material that effectively absorbs and dissipates vibrational energy. This characteristic is particularly beneficial in high-speed machinery, where excessive vibrations can lead to premature wear, reduced precision, and increased noise levels. By incorporating phenolic cotton cloth laminates into machine designs, engineers can significantly improve operational smoothness and extend the lifespan of critical components.

Low Friction Coefficient

One of the most advantageous properties of phenolic cotton cloth laminates is their inherently low friction coefficient. This attribute makes them excellent choices for applications involving moving parts or sliding surfaces. The reduced friction not only minimizes wear and tear but also contributes to energy efficiency in machine operations. Components made from these laminates can operate with less resistance, resulting in smoother movements and reduced heat generation. This low-friction characteristic is particularly valuable in bearings, bushings, and other interfaces where minimizing friction is crucial for optimal performance and longevity.

Self-Lubricating Properties

Phenolic cotton cloth laminates exhibit self-lubricating properties, further enhancing their suitability for use in machine parts subject to constant motion or intermittent contact. This self-lubrication is attributed to the microscopic structure of the material, which allows for the retention and slow release of lubricants over time. As a result, components made from these laminates can operate efficiently even in conditions where traditional lubrication methods may be impractical or insufficient. This self-lubricating nature contributes to reduced maintenance requirements and extended service life of machine parts, particularly in applications where regular lubrication is challenging or undesirable.

Common Use Cases in Industrial, Textile, and Automotive Machinery

Industrial Machinery Applications

In the realm of industrial machinery, phenolic cotton cloth laminated sheets find extensive use due to their exceptional mechanical and electrical properties. These materials are commonly employed in the fabrication of large gears, where their high strength and wear resistance are crucial for reliable power transmission in heavy-duty equipment. The laminates are also utilized in the construction of jigs and fixtures, providing stable and durable platforms for manufacturing processes. In pumps and compressors, phenolic cotton cloth components serve as efficient seals and wear plates, capitalizing on the material's low friction and chemical resistance properties to enhance performance and longevity in demanding industrial environments.

Textile Machinery Components

The textile industry heavily relies on phenolic cotton cloth laminated sheets for various machinery components. These materials are particularly well-suited for parts that require high dimensional stability and resistance to wear, such as shuttles, bobbins, and tension rollers. The low friction coefficient of phenolic laminates contributes to smoother operation of textile machinery, reducing fiber damage and improving overall production quality. Additionally, the material's ability to withstand high temperatures makes it ideal for components in dyeing and finishing equipment, where exposure to heat and chemicals is common. The use of phenolic cotton cloth laminates in textile machinery results in increased efficiency, reduced maintenance, and improved product consistency.

Automotive Sector Applications

In the automotive industry, phenolic cotton cloth laminated sheets play a crucial role in various under-the-hood applications and structural components. These materials are frequently used in the production of gaskets and seals, where their resistance to oils, fuels, and high temperatures is invaluable. The vibration damping properties of phenolic laminates make them excellent choices for components in engine mountings and suspension systems, contributing to reduced noise and improved ride comfort. Furthermore, these materials find application in electrical systems as insulators and supports, leveraging their excellent dielectric properties and dimensional stability. The use of phenolic cotton cloth laminates in automotive manufacturing contributes to vehicle reliability, performance, and longevity under diverse operational conditions.

Conclusion

Phenolic cotton cloth laminated sheets have proven to be indispensable materials in the world of machinery. Their unique combination of strength, thermal stability, chemical resistance, and low friction properties makes them ideal for a wide range of applications across industrial, textile, and automotive sectors. As machinery continues to evolve, the versatility and reliability of phenolic cotton cloth laminates ensure their ongoing relevance in engineering solutions. By leveraging these materials, manufacturers can enhance machine performance, reduce maintenance requirements, and ultimately improve operational efficiency across various industries.

Contact Us

For more information about our high-quality phenolic cotton cloth laminated sheets and how they can benefit your machinery applications, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your specific needs.