Understanding the Composition and Properties of FR4 Fiberglass Sheet

The Makeup of FR4 Fiberglass Sheet

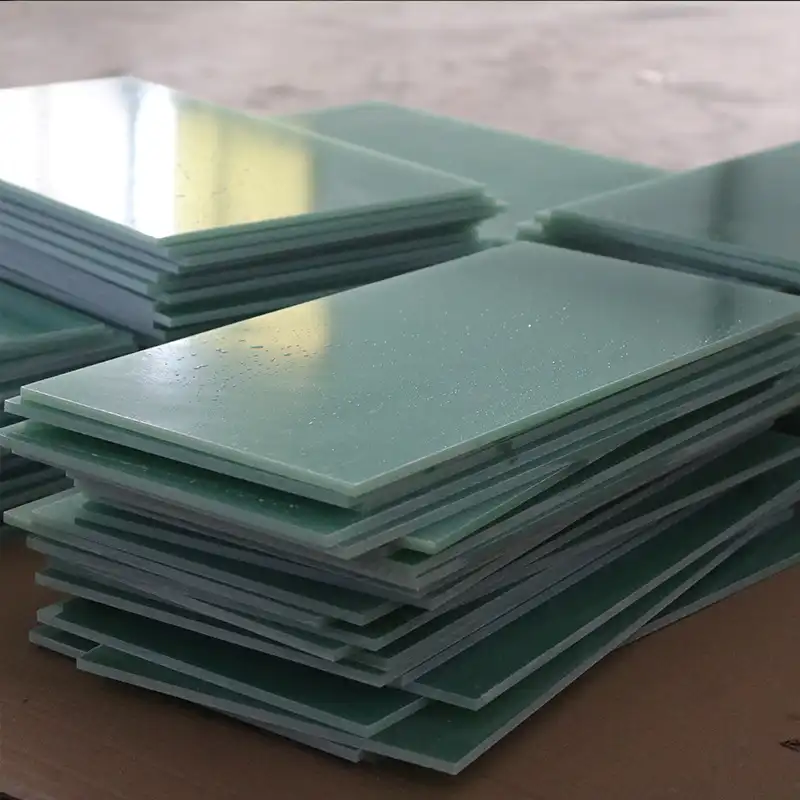

FR4 fiberglass sheet is a composite material consisting of woven glass fiber fabric impregnated with epoxy resin. The glass fibers provide strength and dimensional stability, while the epoxy resin binds the fibers together and contributes to the material's electrical and thermal insulation properties. This unique composition results in a versatile material that combines high strength, excellent electrical insulation, and remarkable heat resistance.

Key Properties of FR4 Epoxy Sheet

Beyond its impressive heat resistance, FR4 epoxy sheet boasts several other notable properties. It exhibits low water absorption, high mechanical strength, and excellent dimensional stability across a wide temperature range. The material also demonstrates good chemical resistance and maintains its electrical properties under varying environmental conditions. These characteristics make FR4 fiberglass sheet a popular choice in industries requiring reliable, high-performance insulation materials.

Thermal Conductivity and Expansion

While FR4 fiberglass sheet excels in heat resistance, it's important to note its thermal conductivity and expansion properties. The material has relatively low thermal conductivity, which contributes to its insulation capabilities. However, it does have a coefficient of thermal expansion that engineers must consider when designing applications involving temperature fluctuations. Understanding these thermal properties is crucial for optimizing the use of FR4 epoxy sheet in various applications.

Applications Leveraging the Heat Resistance of FR4 Fiberglass Sheet

Electronics and Circuit Boards

The high heat resistance of FR4 fiberglass sheet makes it an ideal substrate for printed circuit boards (PCBs). In this application, the material's ability to withstand the heat generated during soldering processes and normal operation of electronic components is crucial. The stability of FR4 at elevated temperatures ensures the integrity and reliability of electronic circuits, even in demanding environments.

Industrial Insulation

FR4 epoxy sheet finds extensive use in industrial insulation applications where high temperatures are encountered. Its heat resistance properties make it suitable for insulating various types of equipment, including transformers, motors, and generators. The material's ability to maintain its insulation properties at elevated temperatures contributes to the safety and efficiency of industrial machinery and electrical systems.

Aerospace and Automotive Industries

In aerospace and automotive applications, FR4 fiberglass sheet is utilized for its combination of heat resistance, lightweight nature, and mechanical strength. It's employed in the construction of interior panels, electrical enclosures, and insulation components. The material's ability to withstand high temperatures while maintaining its structural integrity is particularly valuable in these sectors, where weight reduction and thermal management are critical considerations.

Factors Influencing the Heat Resistance of FR4 Fiberglass Sheet

Resin Formulation

The specific formulation of the epoxy resin used in FR4 fiberglass sheet plays a significant role in determining its heat resistance. Advanced resin systems can be engineered to enhance the material's thermal stability, pushing the boundaries of its heat resistance capabilities. Manufacturers continually research and develop new resin formulations to meet the evolving demands of industries requiring materials with ever-higher heat resistance.

Glass Fiber Content and Weave

The content and weave pattern of the glass fibers in FR4 epoxy sheet influence its overall properties, including heat resistance. Higher glass content generally correlates with improved thermal stability. Additionally, the weave pattern of the glass fibers can affect the material's heat distribution and overall thermal performance. Balancing these factors allows manufacturers to tailor the heat resistance properties of FR4 fiberglass sheet for specific applications.

Manufacturing Process and Quality Control

The manufacturing process and quality control measures employed in producing FR4 fiberglass sheet significantly impact its final properties, including heat resistance. Factors such as curing temperature, pressure, and duration can affect the crosslinking of the epoxy resin, which in turn influences the material's thermal stability. Stringent quality control processes ensure consistency in the heat resistance properties of FR4 epoxy sheet across production batches.

Conclusion

FR4 fiberglass sheet stands out as a remarkable material, offering high heat resistance alongside a host of other beneficial properties. Its ability to withstand temperatures up to 140°C for continuous use, with short-term exposure limits reaching 180°C, makes it an invaluable asset in numerous industries. From electronics to aerospace, the thermal stability of FR4 epoxy sheet continues to play a crucial role in advancing technology and improving product performance. As research in material science progresses, we can anticipate further enhancements in the heat resistance capabilities of FR4 fiberglass sheet, opening doors to new applications and innovations across various sectors.

Contact Us

If you're seeking high-quality FR4 fiberglass sheet for your applications, don't hesitate to reach out to us. Our team of experts is ready to assist you in finding the perfect solution for your needs. Contact us today at info@jhd-material.com to learn more about our products and how we can support your projects.