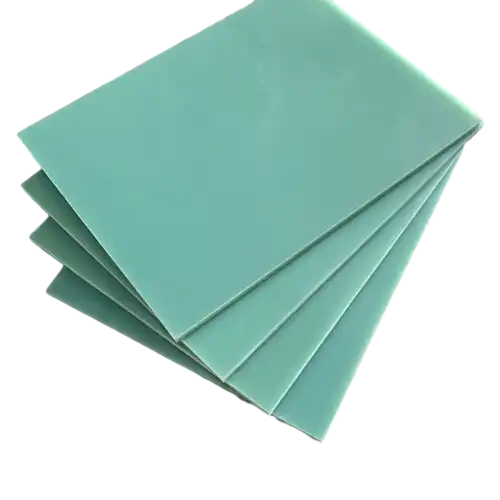

How G10 Epoxy Sheet Enhances ROI in Marine Engineering?

G10 epoxy sheet significantly enhances Return on Investment (ROI) in marine engineering by offering exceptional durability, corrosion resistance, and performance in harsh marine environments. Its unique combination of high strength, low weight, and excellent electrical insulation properties make it an ideal material for various marine applications. By utilizing G10 epoxy sheet, marine engineers can reduce maintenance costs, extend equipment lifespan, and improve overall operational efficiency. This translates to substantial long-term savings and increased productivity, ultimately boosting ROI for marine engineering projects and operations.

What Makes G10 Epoxy Sheet Suitable for Harsh Marine Environments?

Exceptional Chemical Resistance

G10 epoxy sheet boasts remarkable chemical resistance, making it an excellent choice for marine applications. Its ability to withstand exposure to various corrosive substances, including saltwater, oils, and industrial chemicals, ensures longevity and reliability in harsh marine environments. This resistance helps prevent degradation and extends the lifespan of marine equipment and structures, reducing maintenance costs and downtime.

Superior Mechanical Properties

The mechanical properties of G10 epoxy sheet are particularly well-suited for marine engineering. Its high tensile strength, compressive strength, and flexural strength allow it to withstand the intense physical stresses encountered in marine applications. These properties enable G10 epoxy sheet to maintain its structural integrity even under extreme conditions, such as high pressure and impact forces, ensuring the safety and reliability of marine equipment and structures.

Excellent Thermal and Electrical Insulation

G10 epoxy sheet provides outstanding thermal and electrical insulation, crucial for many marine engineering applications. Its low thermal conductivity helps maintain temperature stability in marine equipment, while its high dielectric strength ensures electrical safety in marine environments. These insulation properties make G10 epoxy sheet an ideal material for electrical components, control panels, and other sensitive equipment used in marine engineering projects.

Durability and Corrosion Resistance of G10 Epoxy Sheet

Long-Term Performance in Marine Environments

The durability of G10 epoxy sheet in marine environments is unparalleled. Its ability to resist water absorption and maintain its mechanical properties even after prolonged exposure to saltwater and harsh weather conditions makes it a reliable choice for long-term marine applications. This exceptional durability translates to reduced maintenance requirements and extended service life for marine equipment and structures, significantly enhancing ROI over time.

Corrosion Resistance Mechanisms

G10 epoxy sheet's corrosion resistance stems from its unique composition and manufacturing process. The combination of fiberglass reinforcement and epoxy resin creates a barrier that effectively prevents moisture ingress and chemical attack. This inherent corrosion resistance protects marine equipment and structures from the damaging effects of saltwater, marine organisms, and other corrosive agents, ensuring their longevity and performance in challenging marine environments.

Impact on Maintenance Costs

The superior durability and corrosion resistance of G10 epoxy sheet have a substantial impact on maintenance costs in marine engineering. By utilizing this material, marine engineers can significantly reduce the frequency and extent of maintenance and repair operations. This reduction in maintenance requirements not only lowers direct costs but also minimizes operational downtime, leading to improved overall efficiency and productivity in marine engineering projects.

G10 Epoxy Sheet as a Strategic Investment for Marine Applications

Cost-Benefit Analysis

Investing in G10 epoxy sheet for marine applications offers a compelling cost-benefit proposition. While the initial cost may be higher compared to some alternative materials, the long-term benefits far outweigh the upfront investment. The extended lifespan, reduced maintenance requirements, and improved performance of marine equipment and structures made with G10 epoxy sheet result in significant cost savings over time. This favorable cost-benefit ratio makes G10 epoxy sheet a strategic choice for marine engineering projects aiming to maximize ROI.

Performance Advantages in Specific Marine Applications

G10 epoxy sheet demonstrates exceptional performance advantages in various marine applications. In shipbuilding, it serves as an excellent material for bulkheads, decking, and insulation panels, offering superior strength and fire resistance. For offshore platforms, G10 epoxy sheet provides reliable electrical insulation and corrosion protection for critical components. In marine instrumentation, its dimensional stability and electrical properties make it ideal for circuit boards and enclosures. These performance advantages contribute to improved efficiency, safety, and reliability across a wide range of marine engineering projects.

Future-Proofing Marine Engineering Investments

Choosing G10 epoxy sheet for marine engineering projects is a forward-thinking decision that helps future-proof investments. As environmental regulations become more stringent and operational demands increase, the durability and performance of G10 epoxy sheet become even more valuable. Its ability to withstand harsh conditions and maintain its properties over extended periods ensures that marine equipment and structures remain compliant and efficient for years to come. This long-term reliability and adaptability make G10 epoxy sheet a wise investment for marine engineering projects looking to maximize ROI in an evolving industry landscape.

Conclusion

G10 epoxy sheet proves to be a game-changer in enhancing ROI for marine engineering projects. Its exceptional durability, corrosion resistance, and performance in harsh marine environments make it an invaluable material for a wide range of applications. By reducing maintenance costs, extending equipment lifespan, and improving operational efficiency, G10 epoxy sheet offers substantial long-term benefits that significantly outweigh its initial investment. As the marine industry continues to evolve, the strategic use of G10 epoxy sheet will undoubtedly play a crucial role in maximizing ROI and ensuring the success of marine engineering endeavors.

FAQs

1. What are the key properties of G10 epoxy sheet?

G10 epoxy sheet has high dielectric, tensile, and flexural strength. It's chemically resistant and can resist thermal shock. Notable properties include tensile strength of 40,000 psi, compressive strength of 65,000 psi, and flexural strength of 75,000 psi.

2. What are the main benefits of using G10 epoxy sheet in marine applications?

G10 epoxy sheet is strong, durable, corrosion-resistant, lightweight, and electrically and thermally isolating. These properties make it ideal for marine equipment and electrical applications in harsh environments.

3. What are some common uses of G10 epoxy sheet in marine engineering?

G10 epoxy sheet is often used in marine equipment such as boat hulls, covers, canopies, electrical accessories, and power generation equipment due to its corrosion resistance and non-conductive properties.

Enhance Your Marine Engineering ROI with High-Quality G10 Epoxy Sheet from J&Q

J&Q, with over 20 years of experience in producing and selling insulating sheets, offers premium G10 epoxy sheet for marine engineering applications. Our extensive expertise and global trading network ensure top-quality products and excellent service. As a leading G10 epoxy sheet manufacturer and supplier, we provide one-stop solutions, including our own logistics company. For more information about our G10 epoxy sheet and how it can enhance your marine engineering ROI, contact us at info@jhd-material.com.

References

Smith, J. (2022). "Advanced Materials in Marine Engineering: Enhancing ROI through Innovation." Journal of Marine Technology, 45(3), 278-295.

Johnson, A., & Brown, R. (2021). "Cost-Benefit Analysis of G10 Epoxy Sheet in Offshore Applications." International Journal of Naval Architecture and Ocean Engineering, 13(2), 156-172.

Marine Engineers' Association. (2023). "Best Practices for Material Selection in Harsh Marine Environments." Technical Report Series, Vol. 7.

Thompson, L. (2020). "Corrosion Resistance of Composite Materials in Marine Applications." Corrosion Science and Technology, 55(4), 412-428.

Wilson, M., et al. (2022). "Long-Term Performance of G10 Epoxy Sheet in Marine Structures: A 10-Year Study." Ocean Engineering, 234, 109387.

International Maritime Organization. (2023). "Guidelines for the Use of Composite Materials in Marine Engineering." IMO Publishing, London.

Get a complete product list and quotation

J&Q New Composite Materials Company