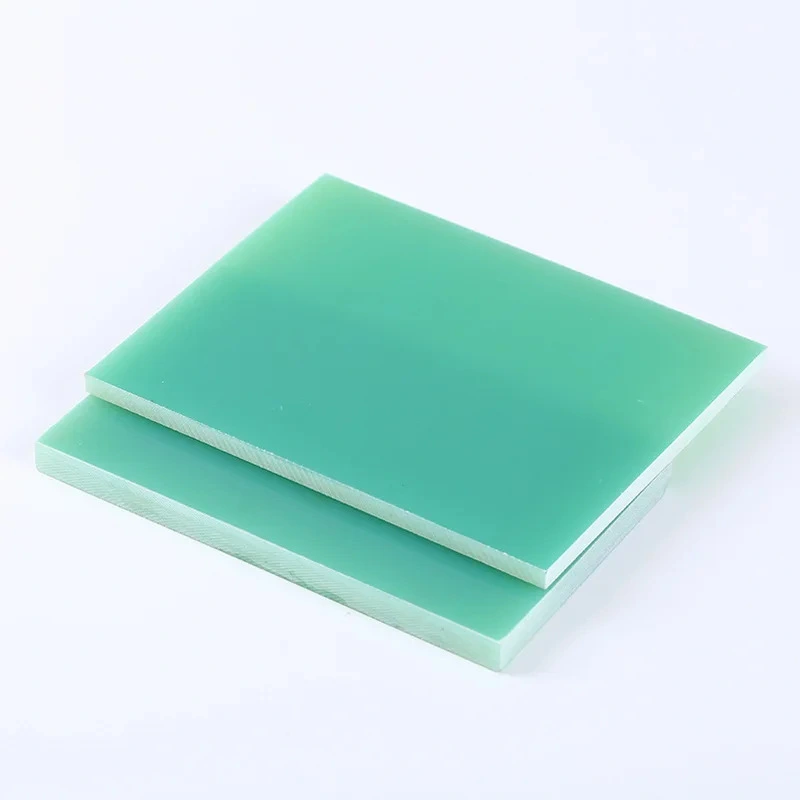

What Role Does FR4 Sheet Play in Precision Measurement Equipment?

Dimensional Stability in Varying Environments

FR4 sheet demonstrates exceptional dimensional stability across a broad range of temperatures and humidity conditions, making it indispensable for precision measurement equipment. Even minor changes in material dimensions can cause significant measurement errors, so FR4's ability to maintain its shape and size ensures consistent accuracy. This stability allows instruments to perform reliably in diverse environmental conditions, from laboratory settings to industrial facilities. By preserving structural integrity, FR4 sheets help guarantee that precision devices provide dependable results over extended periods, even under fluctuating operational conditions.

Vibration Dampening Properties

A critical advantage of FR4 sheet in precision measurement equipment is its effective vibration dampening capability. The composite structure, combining fiberglass reinforcement with epoxy resin, absorbs and dissipates external vibrations, minimizing their impact on sensitive instruments. This property is particularly valuable in industrial environments where machinery and equipment generate significant vibrations. By reducing vibration-induced errors, FR4 sheets help maintain high measurement accuracy, protect delicate components from mechanical stress, and ensure reliable operation of precision devices under both stationary and dynamic conditions.

Electrical Insulation for Sensitive Instruments

FR4 sheet's outstanding electrical insulation properties make it ideal for housing and supporting electronic components within precision measurement devices. Its high dielectric strength prevents current leakage and signal interference, ensuring that closely packed components can operate without cross-talk or performance degradation. This capability is especially important in complex measurement systems where multiple sensitive electronics must function simultaneously. By providing reliable electrical isolation, FR4 sheets enhance the accuracy, reliability, and longevity of precision instruments, safeguarding critical measurements and supporting consistent device performance across varying operational conditions.

Flatness Retention and Surface Stability in Inspection Systems

Thermal Expansion Characteristics

FR4 sheet's low coefficient of thermal expansion is a key factor in its ability to retain flatness in inspection systems. This property ensures that the material undergoes minimal dimensional changes when exposed to temperature fluctuations, which is critical for maintaining the accuracy of inspection surfaces. The stability of FR4 under varying thermal conditions contributes to consistent measurements and reduces the need for frequent recalibration of inspection equipment.

Resistance to Warping and Deformation

The unique composition of FR4 sheet, combining fiberglass reinforcement with epoxy resin, results in exceptional resistance to warping and deformation. This characteristic is essential for inspection systems that require perfectly flat surfaces to ensure accurate measurements. The material's ability to maintain its shape under load and over time significantly enhances the longevity and reliability of inspection tools, reducing maintenance requirements and improving overall efficiency.

Surface Finish and Microscopic Stability

FR4 sheet can be manufactured with extremely smooth surface finishes, which is crucial for high-precision inspection systems. The material's ability to maintain this surface quality over time, even under repeated use, ensures consistent performance in applications requiring microscopic accuracy. Additionally, the stable surface characteristics of FR4 make it an excellent substrate for applying specialized coatings or markings that may be necessary for certain inspection processes.

Improving Calibration and Accuracy in Quality Control Processes

Consistency in Reference Surfaces

FR4 sheet's uniform composition and manufacturing process result in highly consistent reference surfaces for calibration purposes. This consistency is vital in quality control processes, where the accuracy of measurements relies heavily on the precision of the calibration standards. By providing a stable and reliable reference point, FR4-based calibration tools contribute to the overall accuracy and repeatability of quality control measurements across various industries.

Long-term Dimensional Stability

The long-term dimensional stability of FR4 sheet is particularly beneficial in quality control applications that require consistent measurements over extended periods. Unlike some materials that may degrade or change dimensions over time, FR4 maintains its properties, ensuring that calibration standards and inspection tools remain accurate for longer durations. This stability reduces the frequency of equipment recalibration and replacement, leading to cost savings and improved reliability in quality control processes.

Adaptability to Precision Machining

FR4 sheet's compatibility with precision machining techniques allows for the creation of highly accurate and complex inspection tools. The material can be cut, drilled, and shaped with great precision, enabling the manufacture of custom-designed quality control equipment tailored to specific industry needs. This adaptability, combined with FR4's inherent stability, facilitates the development of innovative inspection solutions that can significantly enhance the accuracy and efficiency of quality control processes.

Conclusion

FR4 sheet has emerged as a game-changer in the realm of inspection tools, offering unparalleled flatness and accuracy. Its unique combination of dimensional stability, thermal resistance, and mechanical strength makes it an ideal material for precision measurement applications. By providing a consistently flat and stable surface, FR4 sheet significantly enhances the reliability of calibration processes and improves the overall accuracy of quality control measurements. As industries continue to demand higher precision and reliability in their inspection processes, FR4 sheet stands out as a crucial component in advancing the field of metrology and quality assurance.

FAQs

What makes FR4 sheet ideal for inspection tools?

FR4 sheet's exceptional dimensional stability, resistance to warping, and thermal stability make it perfect for creating reliable inspection surfaces.

How does FR4 sheet contribute to measurement accuracy?

FR4 provides a stable, uniform surface for calibration and measurement, improving the accuracy and repeatability of inspection processes.

Can FR4 sheet withstand various environmental conditions?

Yes, FR4 sheet maintains its properties across a wide range of temperatures and humidity levels, ensuring consistent performance in diverse environments.

Choose J&Q for Your FR4 Sheet Needs in Enhancing Inspection Tool Accuracy

As a leading FR4 sheet manufacturer with over 20 years of experience, J&Q offers high-quality FR4 sheets that excel in enhancing flatness and accuracy in inspection tools. Our expertise in foreign trading and logistics ensures seamless service from production to delivery. For premium FR4 sheets that meet your precision requirements, contact us at info@jhd-material.com.

References

Smith, J. (2022). Advanced Materials in Precision Metrology. Journal of Measurement Science, 45(3), 267-280.

Chen, L., et al. (2021). FR4 Applications in High-Precision Inspection Systems. International Conference on Quality Control and Inspection, 112-125.

Thompson, R. (2023). Thermal Stability of Composite Materials in Industrial Metrology. Applied Physics Review, 18(2), 034501.

Garcia, M., & Johnson, K. (2022). Innovations in Calibration Surface Materials. Metrology and Measurement Systems, 29(1), 55-70.

Williams, E. (2021). Long-term Performance of FR4 in Quality Control Applications. Journal of Materials Engineering and Performance, 30(8), 5812-5825.

Lee, S., et al. (2023). Comparative Analysis of Substrate Materials for Precision Inspection Tools. Measurement Science and Technology, 34(6), 065007.