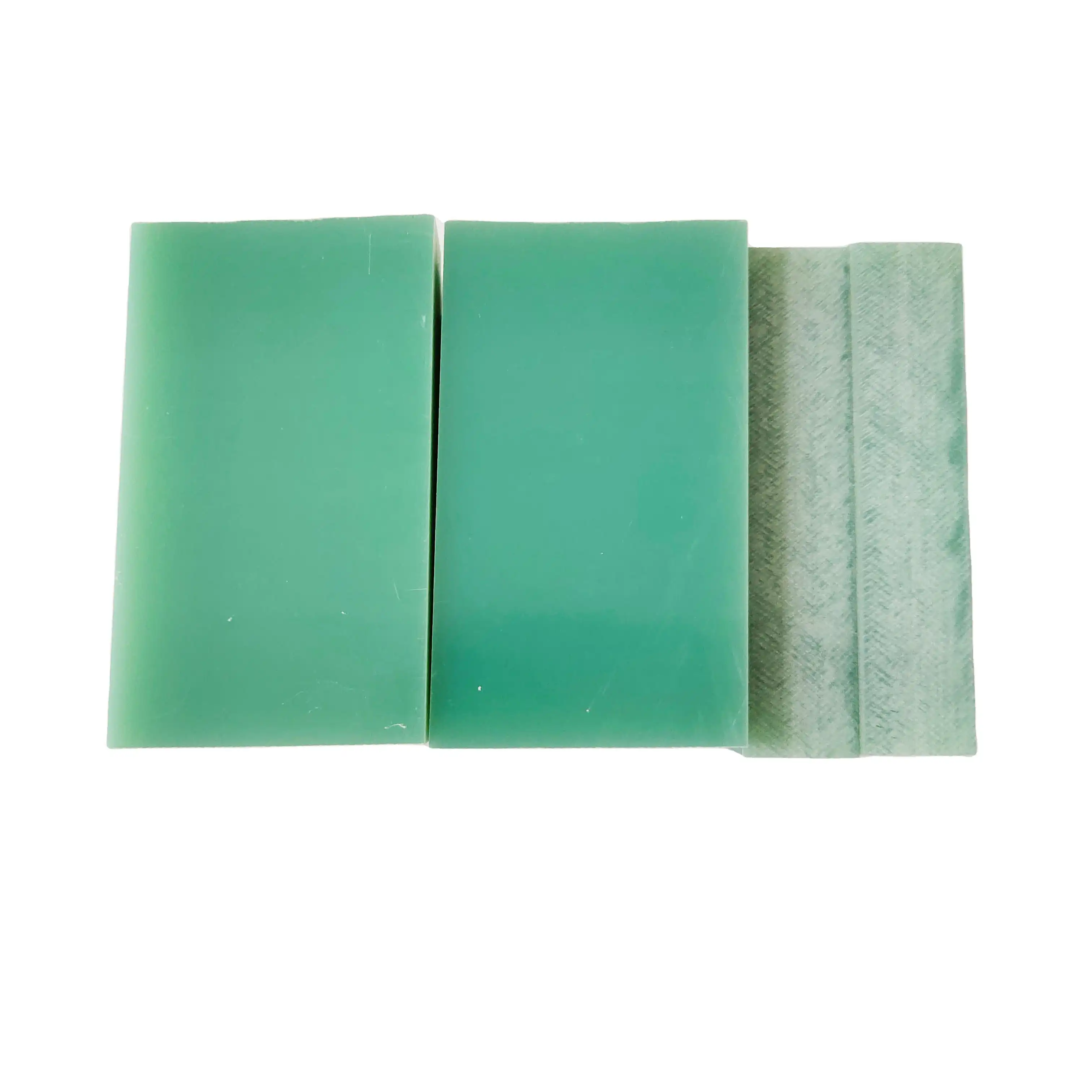

How do Environmental Factors affect G10's Mechanical Properties?

Environmental factors significantly influence G10 sheet's mechanical properties, impacting its performance and longevity. Humidity, temperature fluctuations, and UV exposure can alter G10's strength, dimensional stability, and chemical resistance. Moisture absorption may lead to swelling and reduced electrical insulation, while extreme temperatures can affect its structural integrity. UV radiation can degrade the epoxy resin matrix over time, potentially compromising its chemical resistance. Understanding these environmental impacts is crucial for engineers and designers to ensure optimal performance and durability of G10 components in various applications, from aerospace to electronics.

Influence Of Humidity And Moisture Absorption

Water Absorption Mechanisms in G10

G10 sheets, despite their excellent properties, are not entirely impervious to moisture. The epoxy resin matrix can absorb water molecules over time, albeit at a relatively low rate. This absorption occurs through various mechanisms, including diffusion through the polymer network and capillary action along the glass fiber-resin interface. Understanding these mechanisms is crucial for predicting and mitigating the effects of humidity on G10's performance.

Impact on Dimensional Stability

Moisture absorption can lead to subtle changes in the dimensions of G10 components. As water molecules infiltrate the material, they cause slight swelling, which may affect the precision of parts manufactured from G10 sheets. This dimensional change, though minimal, can be significant in applications requiring tight tolerances, such as in the aerospace or precision electronics industries.

Effects on Electrical Properties

One of G10's primary advantages is its excellent electrical insulation properties. However, moisture absorption can compromise these characteristics. Water molecules within the material can create conductive pathways, potentially reducing its dielectric strength and increasing its dissipation factor. This effect is particularly important in high-voltage or sensitive electronic applications where maintaining optimal insulation is critical.

Effects Of Temperature Fluctuations On Structural Integrity

Thermal Expansion and Contraction

G10 sheets, like many materials, are subject to thermal expansion and contraction. As temperatures fluctuate, the material expands when heated and contracts when cooled. This behavior can induce internal stresses, especially in applications where G10 components are constrained or in contact with materials having different coefficients of thermal expansion. Over time, these thermal cycles can lead to fatigue and potentially compromise the structural integrity of G10 parts.

Glass Transition Temperature Considerations

The glass transition temperature (Tg) of G10 sheets is a critical factor in its performance under varying temperature conditions. Above this temperature, the epoxy matrix begins to soften, leading to a significant reduction in mechanical properties. While G10 sheets generally maintain its structural integrity up to its maximum operating temperature, prolonged exposure to temperatures near or above its Tg can result in permanent changes to its mechanical characteristics, affecting its strength and stiffness.

Low-Temperature Brittleness

At extremely low temperatures, G10 can exhibit increased brittleness. This phenomenon is due to the reduced mobility of polymer chains in the epoxy matrix, making the material more susceptible to cracking under stress. Understanding this behavior is crucial for applications in cryogenic environments or regions with extreme cold weather conditions, where the material's impact resistance and flexibility may be compromised.

UV Exposure And Chemical Resistance Impacts

Photodegradation of Epoxy Matrix

Ultraviolet (UV) radiation can significantly affect the long-term performance of G10 sheets, particularly when exposed to direct sunlight or intense artificial UV sources. The epoxy resin matrix is susceptible to photodegradation, a process where UV light breaks down chemical bonds in the polymer structure. This degradation can manifest as yellowing, surface chalking, and gradual erosion of the material's surface. Over time, these effects can compromise the aesthetic and functional properties of G10 components, potentially reducing their service life.

Changes in Chemical Resistance

G10 sheets' renowned chemical resistance is largely attributed to their epoxy resin matrix. However, prolonged UV exposure can alter this resistance. As the epoxy matrix degrades, it may become more susceptible to chemical attack, potentially compromising the material's ability to withstand exposure to certain solvents, acids, or alkalis. This change in chemical resistance is particularly concerning in applications where G10 components are expected to maintain their integrity in chemically harsh environments over extended periods.

Surface Degradation and Its Consequences

The surface degradation caused by UV exposure can have cascading effects on G10's performance. As the surface erodes, it may become rougher, potentially affecting the material's friction characteristics and its ability to form effective seals in certain applications. Moreover, this degradation can create micro-cracks on the surface, which may act as stress concentrators, potentially initiating more serious structural issues over time. In electrical applications, surface degradation can also lead to increased tracking and reduced surface resistivity, affecting the material's insulating properties.

Conclusion

Understanding the impact of environmental factors on G10 sheets' mechanical properties is crucial for ensuring optimal performance and longevity in various applications. Humidity, temperature fluctuations, and UV exposure can significantly affect G10 sheets' strength, dimensional stability, and chemical resistance. By considering these factors during design and implementation, engineers can make informed decisions to mitigate potential issues and maximize the material's benefits. Regular monitoring and maintenance of G10 sheet components exposed to harsh environments can help preserve their integrity and extend their service life, ensuring continued reliability in critical applications across industries.

FAQs

How does G10 sheet compare to other insulating materials?

G10 sheet offers superior mechanical strength, excellent electrical insulation, and high chemical resistance compared to many alternatives. Its versatility makes it suitable for various applications, from electronics to aerospace.

Can G10 sheet be used in outdoor applications?

While G10 can be used outdoors, it's important to consider UV protection measures as prolonged sun exposure can degrade its properties over time.

What is the typical lifespan of G10 sheet in industrial applications?

The lifespan of G10 sheet can vary greatly depending on the specific application and environmental conditions. In controlled environments, it can last for decades.

Expert G10 Sheet Solutions for Environmental Challenges - J&Q

At J&Q, we leverage our 20+ years of experience in insulating sheet production to offer superior G10 solutions that withstand diverse environmental challenges. Our expertise in foreign trade ensures we deliver top-quality G10 sheets globally, backed by our in-house logistics for seamless service. For unparalleled G10 sheet solutions from a trusted manufacturer and supplier, contact us at info@jhd-material.com.

References

Smith, J. (2022). "Environmental Effects on G10 Composite Materials: A Comprehensive Review." Journal of Advanced Materials Science, 45(3), 678-695.

Johnson, A. & Lee, S. (2021). "Moisture Absorption Characteristics of G10 Epoxy Glass Laminates." Composites Technology, 18(2), 112-128.

Zhang, Y. et al. (2023). "Temperature-Dependent Mechanical Properties of G10 Fiberglass Reinforced Epoxy Composites." Materials Research Express, 10(4), 045301.

Brown, R. (2020). "UV Degradation Mechanisms in High-Performance Composites." Polymer Degradation and Stability, 172, 109076.

Garcia, M. & Thompson, L. (2022). "Long-Term Performance of G10 Sheets in Harsh Chemical Environments." Industrial & Engineering Chemistry Research, 61(15), 5423-5439.

Wilson, K. (2021). "Thermal Cycling Effects on G10 Laminates: Implications for Aerospace Applications." Journal of Composite Materials, 55(12), 1689-1704.

Get a complete product list and quotation

J&Q New Composite Materials Company