Inherent Flame Retardancy and Arc Resistance Properties

Chemical Composition and Flame Retardant Mechanisms

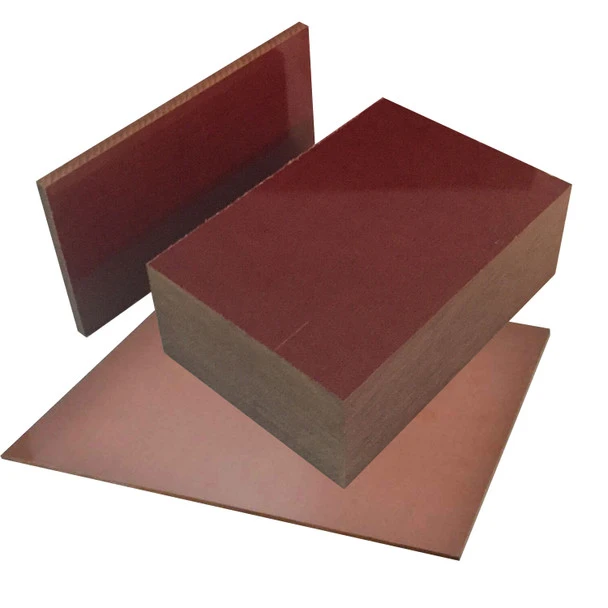

CE phenolic sheet derives its flame retardant properties from its unique chemical structure. The phenol-formaldehyde resin matrix, reinforced with cotton fabric, creates a robust material that inherently resists ignition. When exposed to high temperatures, the phenolic compounds undergo a process called char formation, creating a protective layer that impedes flame propagation and limits oxygen access to the underlying material.

Arc Resistance and Its Importance in Electrical Safety

Arc resistance is a crucial property of CE phenolic sheet that contributes significantly to electrical safety. This material exhibits exceptional resistance to electrical arcing, which occurs when an electric current jumps across a gap in a circuit. The high arc resistance of CE phenolic sheet helps prevent the formation of conductive carbon paths on its surface, maintaining insulation integrity even under severe electrical stress conditions.

Comparative Analysis with Other Insulating Materials

When compared to other insulating materials, CE phenolic sheet often outperforms in terms of flame retardancy and arc resistance. Unlike some thermoplastics that melt or deform under high heat, CE phenolic sheet maintains its structural integrity. Its superior arc resistance surpasses that of many common insulators, making it an ideal choice for applications where electrical safety is paramount.

How Does It Prevent Electrical Tracking and Failures?

Understanding Electrical Tracking Phenomena

Electrical tracking is a surface degradation process caused by electrical stress, moisture, and contaminants that form conductive carbon paths across insulating materials. Over time, these paths can lead to short circuits or insulation breakdown. CE phenolic sheet effectively resists this phenomenon due to its tightly bonded molecular structure and thermoset resin composition, which inhibit carbonization under electrical stress. Its dense, non-porous surface minimizes pathways for conductive residue formation, ensuring stable insulation performance even in high-voltage or polluted environments.

Surface Properties and Contamination Resistance

The superior surface quality of CE phenolic sheet plays a vital role in preventing electrical tracking and maintaining insulation reliability. Its low porosity and minimal moisture absorption prevent the buildup of dirt, dust, or conductive contaminants that could initiate tracking. The smooth surface also reduces frictional wear, preserving its insulating barrier over time. In industrial or outdoor conditions where humidity and airborne pollutants are common, CE phenolic sheet's contamination resistance ensures consistent dielectric performance and reduces the risk of electrical flashovers or arcing.

Long-term Performance and Degradation Resistance

CE phenolic sheet is engineered for long-lasting performance, maintaining high dielectric strength even after prolonged exposure to heat, UV radiation, and chemicals. Its thermoset phenolic resin matrix provides stability against oxidation and thermal aging, preventing cracks or weakening over time. This resilience makes it a dependable choice for electrical panels, switchgear, and insulation barriers in harsh operational environments. By minimizing degradation and maintaining mechanical integrity, CE phenolic sheet extends equipment service life, reduces maintenance costs, and enhances overall system safety and efficiency.

Ensuring Compliance with International Electrical Safety Standards

Relevant International Standards and Certifications

CE phenolic sheet meets or exceeds numerous international electrical safety standards. It complies with UL 94 flammability ratings, IEC 60085 thermal classifications, and NEMA grade specifications. These certifications ensure that electrical components manufactured using CE phenolic sheet meet rigorous safety requirements across various industries and applications.

Impact on Design and Manufacturing Processes

The use of CE phenolic sheet in electrical design simplifies compliance with safety standards. Its consistent properties allow engineers to design with confidence, knowing that the material will perform reliably under specified conditions. In manufacturing, the material's machinability and dimensional stability facilitate the production of precision components that meet strict tolerances required by safety standards.

Case Studies of Successful Implementation

Numerous industries have successfully implemented CE phenolic sheet in critical electrical applications. In power distribution equipment, it has been used to manufacture high-voltage insulators that demonstrate exceptional longevity and reliability. Aerospace manufacturers have utilized CE phenolic sheet in avionics systems, leveraging its flame retardancy and low weight. These case studies highlight the material's versatility and its role in enhancing electrical safety across diverse sectors.

Conclusion

CE phenolic sheet stands out as a superior material for improving safety in electrical design. Its inherent flame retardancy, exceptional arc resistance, and ability to prevent electrical tracking make it an invaluable asset in creating safer electrical systems. By ensuring compliance with international safety standards and offering long-term reliability, CE phenolic sheet enables engineers to design and manufacture electrical components with enhanced safety profiles. As the demand for more robust and secure electrical systems continues to grow, the role of CE phenolic sheet in safeguarding both equipment and personnel becomes increasingly vital.

FAQs

What makes CE phenolic sheet suitable for electrical applications?

CE phenolic sheet is ideal for electrical applications due to its high dielectric strength, excellent insulation properties, and inherent flame retardancy. It also offers superior dimensional stability and resistance to electrical tracking.

How does CE phenolic sheet compare to other insulating materials?

CE phenolic sheet often outperforms many other insulating materials in terms of flame retardancy, arc resistance, and long-term reliability. It maintains its properties under harsh conditions better than many thermoplastics.

What are some common applications for CE phenolic sheet in electrical design?

CE phenolic sheet is commonly used in high-voltage insulators, switchgear components, transformer parts, and various electrical enclosures where safety and reliability are critical.

Choose J&Q for Your CE Phenolic Sheet Needs

J&Q, with over two decades of experience in producing and selling insulating sheets, is your trusted CE phenolic sheet supplier. Our extensive knowledge in foreign trading and partnerships with numerous domestic and international companies ensure we deliver top-quality products and exceptional service. As a manufacturer with our own logistics company, we offer a seamless one-stop solution for all your CE phenolic sheet requirements. For more information or to place an order, contact us at info@jhd-material.com.

References

International Electrotechnical Commission. (2020). "IEC 60085:2007 - Electrical insulation - Thermal evaluation and designation."

Underwriters Laboratories. (2019). "UL 94: Standard for Tests for Flammability of Plastic Materials for Parts in Devices and Appliances."

National Electrical Manufacturers Association. (2018). "NEMA LI 1: Industrial Laminated Thermosetting Products."

IEEE Dielectrics and Electrical Insulation Society. (2021). "Advances in Electrical Insulation Materials: Properties and Applications."

American Society for Testing and Materials. (2022). "ASTM D149 - Standard Test Method for Dielectric Breakdown Voltage and Dielectric Strength of Solid Electrical Insulating Materials at Commercial Power Frequencies."

International Conference on Electrical Insulation and Dielectric Phenomena. (2023). "Proceedings: Innovations in Insulating Materials for High Voltage Applications."