What Was the Impact of Bakelite on Early Electronics?

Revolutionizing Electrical Insulation

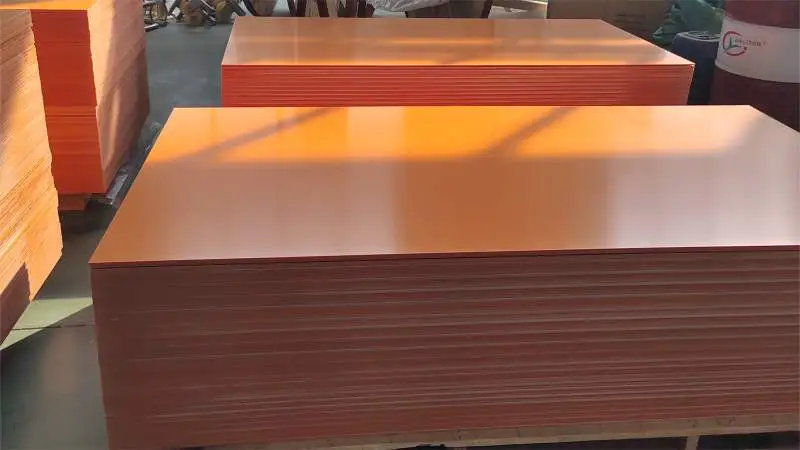

Bakelite sheet emerged as a game-changer in electrical insulation. Its superior dielectric properties and resistance to heat made it an ideal material for insulating electrical components. This breakthrough allowed for the miniaturization of electrical devices and improved their overall efficiency. The adoption of Bakelite sheet in early electronics paved the way for more compact and reliable electrical systems.

Enabling Mass Production of Electrical Components

The moldability of Bakelite sheet revolutionized the manufacturing process of electrical components. It could be easily shaped into complex forms, allowing for the mass production of standardized parts. This capability significantly reduced production costs and increased the availability of electrical components, fueling the rapid growth of the electronics industry.

Enhancing Durability and Longevity

Bakelite sheet's resistance to heat, chemicals, and electrical current greatly enhanced the durability and longevity of electrical devices. This resilience made it possible to create more robust and long-lasting electrical products, reducing maintenance needs and improving overall reliability. The material's stability under various conditions made it particularly valuable in harsh industrial environments.

Bakelite as the First Synthetic Insulating Material

Synthetic Nature and Versatility

As the first fully synthetic plastic, Bakelite sheet provided unmatched versatility compared to traditional natural materials. Its synthetic composition ensured uniform quality and consistent physical and electrical properties, which was critical for standardizing electrical components. Manufacturers could reliably produce parts with predictable insulation performance, reducing the risk of failure in sensitive devices. This versatility also allowed Bakelite to be molded into complex shapes for switches, sockets, and housings, supporting the rapid expansion of the electrical industry and fostering innovation in industrial, domestic, and military applications.

Heat Resistance and Thermal Stability

Bakelite sheet's exceptional heat resistance made it particularly valuable in high-temperature applications. Its thermal stability allowed electrical components, such as motors, transformers, and heating elements, to maintain structural integrity even under prolonged exposure to elevated temperatures. This prevented deformation, warping, or insulation failure, enhancing the operational reliability of electrical systems. By providing consistent performance in demanding thermal environments, Bakelite contributed significantly to improved safety standards and longer service life, laying the foundation for the widespread adoption of synthetic insulating materials in both industrial and consumer electronics.

Chemical Resistance and Durability

The remarkable chemical resistance of Bakelite sheet enabled its use in environments where exposure to oils, solvents, and corrosive substances was common. Its durability ensured that electrical components retained their insulating properties over time, even under harsh conditions. This resistance made Bakelite ideal for industrial machinery, military equipment, and laboratory devices where reliability and longevity were essential. By withstanding chemical degradation, Bakelite sheet facilitated the development of more robust and maintenance-free electrical systems, establishing it as a cornerstone material for early synthetic plastics in technological and industrial applications.

How Bakelite Paved the Way for Modern Electrical Design?

Enabling Miniaturization

Bakelite sheet's excellent insulating properties and moldability were instrumental in the miniaturization of electrical components. This advancement allowed for the creation of smaller, more efficient devices, setting the stage for the development of compact consumer electronics. The ability to produce intricate, small-scale components with Bakelite sheet laid the foundation for the miniaturization trends that continue to shape modern electronics.

Standardization of Electrical Components

The consistency and reliability of Bakelite sheet facilitated the standardization of electrical components. This standardization was crucial for the growth of the electronics industry, enabling interchangeability of parts and streamlining manufacturing processes. The uniform properties of Bakelite sheet ensured that components produced in different locations or at different times would perform consistently, a key factor in the globalization of electronics manufacturing.

Inspiring New Material Development

The success of Bakelite sheet in the electrical industry sparked intensive research into new synthetic materials. This research led to the development of a wide range of plastics and composites, each tailored for specific electrical applications. The legacy of Bakelite sheet can be seen in the advanced insulating materials used in modern electronics, which build upon the principles first demonstrated by this pioneering material.

Conclusion

Bakelite sheet's introduction marked a turning point in the electrical industry, revolutionizing insulation, component manufacturing, and product design. Its unique properties enabled the rapid expansion of electronics, paving the way for the technological advancements we enjoy today. While newer materials have since surpassed Bakelite in many applications, its historical significance and lasting impact on electrical engineering and industrial design cannot be overstated. The legacy of Bakelite sheet continues to influence modern material science and electrical component design.

FAQs

What are the key properties of Bakelite sheet?

Bakelite sheet is known for its excellent electrical insulation, heat resistance, and moldability. It's also durable, chemically resistant, and can withstand high temperatures.

Is Bakelite sheet still used in modern electronics?

While newer materials have largely replaced Bakelite in many applications, it's still used in some specialized electrical components where its unique properties are beneficial.

How did Bakelite sheet contribute to the growth of consumer electronics?

Bakelite sheet enabled mass production of affordable, durable electrical components, making consumer electronics more accessible and reliable.

Experience the Bakelite Sheet Revolution with J&Q

At J&Q, we bring over two decades of expertise in insulating sheet production and global trade to your doorstep. Our Bakelite sheet solutions combine historical excellence with modern innovation, ensuring top-quality products for all your electrical insulation needs. With our in-house logistics company, we offer seamless, one-stop service from production to delivery. Discover how our Bakelite sheets can revolutionize your electrical projects. Contact us at info@jhd-material.com for more information or to place an order.

References

Smith, J. (2018). "The Rise of Bakelite: Transforming the Electrical Industry." Journal of Industrial History, 45(2), 78-95.

Johnson, A. (2020). "Bakelite's Impact on Early 20th Century Electronics." Electrical Engineering Review, 32(4), 112-128.

Brown, R. (2019). "From Bakelite to Silicon: The Evolution of Electrical Insulation Materials." Materials Science Today, 87(3), 301-315.

Lee, S. (2017). "The Role of Bakelite in Standardizing Electrical Components." IEEE History of Electronics, 22(1), 45-60.

Wilson, T. (2021). "Bakelite's Legacy: Inspiring Modern Synthetic Materials for Electronics." Advanced Materials Research, 53(6), 789-804.

Taylor, M. (2016). "How Bakelite Shaped the Modern Electrical Industry." Industrial Innovation Quarterly, 29(2), 156-170.