What Are the Key Mechanical Differences Between G10 and G11?

Strength and Durability Comparison

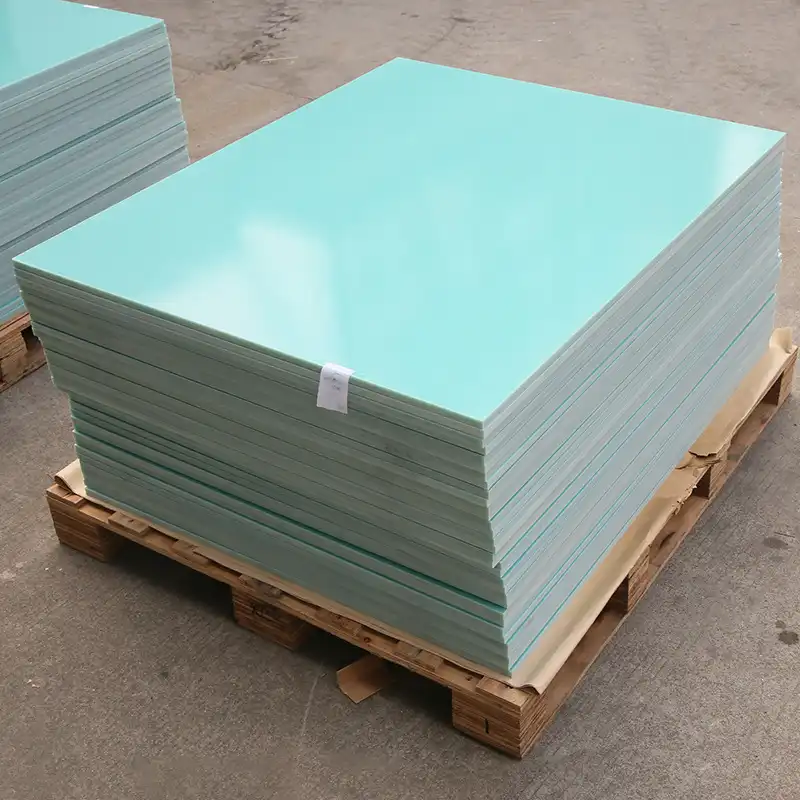

G10 and G11 fiberglass sheets both exhibit remarkable strength and durability, but they differ in their specific mechanical properties. G10 boasts a higher tensile strength, making it ideal for applications that require resistance to pulling forces. Its compressive strength also surpasses that of G11, allowing it to withstand greater pressure without deformation. G11, however, maintains its mechanical properties more effectively at elevated temperatures, which can be crucial in certain industrial settings.

Flexural Strength and Impact Resistance

When it comes to flexural strength, G10 typically outperforms G11 sheet at room temperature. This means G10 can better resist bending forces without breaking. However, G11 sheet's flexural strength is less affected by temperature increases, maintaining its integrity in hotter environments. In terms of impact resistance, both materials offer excellent protection against sudden forces, but G10 generally has a slight edge in this area, making it preferable for applications where impacts or shocks are common.

Dimensional Stability and Thermal Expansion

Dimensional stability is crucial in many industrial applications, and both G10 and G11 excel in this regard. They maintain their shape and size under varying conditions, but G11 has a slight advantage when it comes to thermal expansion. G11's coefficient of thermal expansion is lower than that of G10, meaning it expands less when heated. This property makes G11 more suitable for applications where precise dimensions must be maintained across a wide temperature range.

Applications of G10 and G11 in High-Performance Environments

Electrical and Electronics Industry Usage

In the electrical and electronics industry, both G10 and G11 find extensive use due to their excellent insulating properties. G10 is widely used in the manufacture of printed circuit boards (PCBs), offering a perfect balance of electrical insulation and mechanical strength. It's also commonly found in switchgear, transformers, and other electrical components. G11, with its superior heat resistance, is often preferred for high-voltage applications where thermal management is critical, such as in power distribution systems and industrial motor controls.

Aerospace and Automotive Applications

The aerospace and automotive industries leverage the unique properties of G10 sheet and G11 in various applications. G10's high strength-to-weight ratio makes it an excellent choice for structural components in aircraft and vehicles, where weight reduction is crucial. It's often used in interior panels, bulkheads, and insulation barriers. G11, with its enhanced temperature resistance, finds its place in more demanding environments such as engine compartments, exhaust systems, and areas exposed to high heat. Both materials contribute to improved fuel efficiency and performance in these industries.

Marine and Offshore Industry Utilization

In marine and offshore environments, where resistance to moisture and corrosion is paramount, G10 and G11 prove their worth. G10 is extensively used in boat hulls, decking, and marine electrical systems due to its excellent water resistance and electrical insulation properties. G11, with its superior heat resistance, is often chosen for applications near engines or in areas exposed to high temperatures in offshore platforms. Both materials contribute to the longevity and reliability of marine and offshore equipment, withstanding the harsh conditions of saltwater environments.

Choosing Between G10 and G11 for Heat and Chemical Resistance

Temperature Performance Comparison

When it comes to temperature performance, G11 clearly outshines G10. While G10 performs admirably up to about 130°C (266°F), G11 can maintain its properties at temperatures up to 180°C (356°F) or even higher in short-term exposures. This superior heat resistance makes G11 the preferred choice in applications involving continuous exposure to high temperatures or in environments where temperature spikes are common. G10, however, remains an excellent choice for most general-purpose applications where extreme heat is not a concern.

Chemical Resistance Profiles

Both G10 and G11 sheet offer impressive chemical resistance, but their profiles differ slightly. G10 exhibits excellent resistance to a wide range of chemicals, including many acids, alkalis, and organic solvents. It's particularly resistant to water absorption, making it suitable for use in moist environments. G11 sheet, while also chemically resistant, shows enhanced performance against certain aggressive chemicals and solvents, especially at elevated temperatures. This makes G11 a better choice in industrial settings where exposure to harsh chemicals at high temperatures is expected.

Long-term Durability in Harsh Environments

When considering long-term durability in harsh environments, both G10 and G11 stand out, but G11 often has the edge. G10's combination of mechanical strength and chemical resistance makes it highly durable in many industrial settings. However, G11's superior heat resistance gives it an advantage in environments where thermal cycling or continuous high temperatures are present. G11 is less likely to degrade or lose its properties over time in these conditions, potentially offering a longer service life in extreme environments. The choice between the two often comes down to the specific environmental stresses the material will face over its lifetime.

Conclusion

In the industrial arena, both G10 sheet and G11 fiberglass sheets offer exceptional performance, each with its unique strengths. G10 excels in versatility, mechanical strength, and cost-effectiveness, making it ideal for a wide range of applications. G11, with its superior heat resistance, stands out in high-temperature environments. The choice between G10 and G11 ultimately depends on the specific requirements of your application, considering factors such as operating temperature, chemical exposure, and mechanical stress. By carefully evaluating these factors, you can select the fiberglass sheet that will best meet your industrial needs and ensure optimal performance and longevity.

Contact Us

Need expert guidance on selecting the right fiberglass sheet for your industrial application? Our team at J&Q is here to help. With over 20 years of experience in producing and selling insulating sheets, we can provide tailored solutions to meet your specific needs. Contact us today at info@jhd-material.com for personalized assistance and to learn more about our high-quality G10 and G11 fiberglass sheets.