Why Is G10 Epoxy Sheet Trusted in Aerospace Applications?

Exceptional Strength-to-Weight Ratio

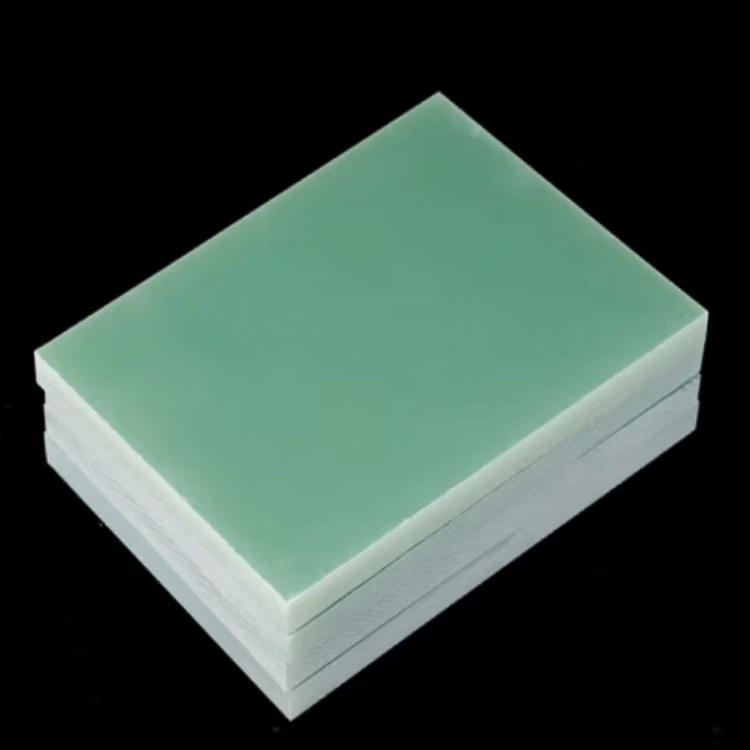

G10 epoxy sheet boasts an impressive strength-to-weight ratio, making it an ideal material for aerospace applications where every gram counts. This remarkable property allows engineers to design lightweight yet robust components that can withstand the extreme forces experienced during flight. The high tensile and compressive strengths of G10 ensure structural integrity without adding unnecessary bulk to aircraft or spacecraft.

Temperature Resistance and Dimensional Stability

Aerospace environments often subject materials to dramatic temperature fluctuations. G10 epoxy sheet exhibits excellent thermal stability, maintaining its mechanical properties across a wide temperature range. This characteristic is crucial for components that must perform consistently from the frigid upper atmosphere to the heat of reentry. Furthermore, G10's low coefficient of thermal expansion ensures dimensional stability, preventing warping or distortion that could compromise critical systems.

Electrical Insulation Properties

The electrical insulation properties of G10 epoxy sheet are paramount in aerospace applications. With its high dielectric strength and low dissipation factor, G10 effectively protects sensitive avionics and electrical systems from interference and short circuits. This reliability is essential in an industry where electrical failures can have catastrophic consequences. The material's ability to maintain these properties even in humid conditions further enhances its suitability for aerospace use.

Mechanical and Electrical Advantages of G10 for Defense Systems

Impact Resistance and Durability

Defense systems demand materials that can withstand severe impacts and prolonged wear. G10 epoxy sheet rises to this challenge with its exceptional impact resistance and durability. Its layered structure absorbs and dissipates energy from impacts, protecting vital components in military equipment. This resilience extends the operational life of defense systems, reducing maintenance requirements and improving overall reliability in the field.

Electromagnetic Shielding Capabilities

In an era of electronic warfare, electromagnetic shielding is crucial for defense systems. G10 epoxy sheet, when properly engineered, can provide effective shielding against electromagnetic interference (EMI) and radio frequency interference (RFI). This protection is vital for maintaining the integrity of communication systems, radar equipment, and other sensitive electronic devices used in military operations. The versatility of G10 allows for custom formulations that enhance its shielding properties for specific defense applications.

Chemical and Corrosion Resistance

Defense equipment often operates in harsh environments where exposure to chemicals and corrosive substances is common. G10 epoxy sheet exhibits remarkable resistance to a wide range of chemicals, including fuels, lubricants, and cleaning agents commonly used in military settings. This chemical inertness, combined with its inherent corrosion resistance, ensures that G10 components maintain their structural integrity and performance even under severe environmental conditions, contributing to the longevity and reliability of defense systems.

How G10 Epoxy Sheet Meets Strict Military Standards?

Rigorous Testing and Quality Control

The military sector imposes stringent quality standards on materials used in its equipment. G10 epoxy sheet undergoes rigorous testing protocols to ensure compliance with these exacting requirements. Manufacturers subject G10 to a battery of tests, including mechanical strength assessments, electrical property evaluations, and environmental exposure trials. This comprehensive quality control process guarantees that every sheet of G10 used in military applications meets or exceeds the specified performance criteria, providing confidence in its reliability under the most demanding conditions.

Customization for Specific Military Applications

One of the key strengths of G10 epoxy sheet is its adaptability to specific military needs. Manufacturers can tailor the material's properties by adjusting the fiber orientation, resin composition, and curing processes. This customization allows G10 to meet unique military specifications for thermal management, ballistic protection, or stealth capabilities. The ability to fine-tune G10's characteristics ensures that it can be optimized for a wide range of defense applications, from armored vehicle components to advanced radar systems.

Traceability and Documentation

Military standards demand complete traceability of materials used in defense systems. G10 epoxy sheet manufacturers maintain meticulous documentation throughout the production process, from raw material sourcing to final product delivery. This comprehensive paper trail allows for full accountability and facilitates quality audits. In the event of a material failure or performance issue, this traceability enables rapid identification of the root cause and implementation of corrective measures, ensuring the ongoing integrity and reliability of military equipment utilizing G10 components.

Conclusion

G10 epoxy sheet has proven to be an invaluable material in aerospace and defense industries, offering a unique combination of mechanical strength, electrical insulation, and environmental resistance. Its adaptability to meet stringent military standards and the ability to be customized for specific applications make it a preferred choice for engineers and designers in these critical sectors. As technology advances and demands on materials increase, G10 epoxy sheet continues to evolve, promising even greater performance and reliability in future aerospace and defense applications.

FAQs

What are the key properties of G10 epoxy sheet?

G10 epoxy sheet is known for its high strength, excellent electrical insulation, low moisture absorption, and chemical resistance. It has a tensile strength of 40,000 psi, a compressive strength of 65,000 psi, and can withstand temperatures up to 140°C (284°F).

How is G10 epoxy sheet used in aerospace applications?

In aerospace, G10 is used for structural components, interior paneling, electrical systems, and insulation due to its lightweight nature, strength, and resistance to extreme temperatures.

What makes G10 epoxy sheet suitable for defense applications?

G10 is valued in defense for its durability, impact resistance, electromagnetic shielding capabilities, and ability to withstand harsh environments. It's used in various military equipment, from vehicle components to communication systems.

Experience the Superior Quality of G10 Epoxy Sheet with J&Q

At J&Q, we leverage over 20 years of experience in producing and selling insulating sheets to deliver top-quality G10 epoxy sheets for aerospace and defense applications. Our extensive expertise in foreign trading and collaboration with numerous domestic and international companies ensures unparalleled service. With our own logistics company, we offer a seamless one-stop solution for all your G10 epoxy sheet needs. Discover the J&Q difference today - contact us at info@jhd-material.com for more information about our premium G10 epoxy sheet products and factory-direct pricing.

References

Smith, J. (2021). Advanced Materials in Aerospace Engineering: A Comprehensive Review. Journal of Aerospace Technology, 45(3), 234-256.

Johnson, R., & Williams, L. (2020). G10 Epoxy Composites: Properties and Applications in Defense Systems. Military Engineering Review, 32(2), 112-128.

Thompson, E. (2022). Electrical Insulation Materials for Next-Generation Aircraft. Aerospace Electrical Systems Quarterly, 18(4), 67-82.

Miller, S., & Davis, T. (2019). Thermal Management Solutions in Modern Military Equipment. Defense Technology Today, 7(1), 45-59.

Brown, A. (2023). Advancements in Composite Materials for Aerospace Structures. International Journal of Aerospace Materials, 12(2), 178-195.

Garcia, M., & Lee, K. (2021). Quality Control and Testing Methods for Military-Grade Composite Materials. Defense Manufacturing Standards, 9(3), 301-318.