Material Composition and Manufacturing Processes

FR4 Composition and Production

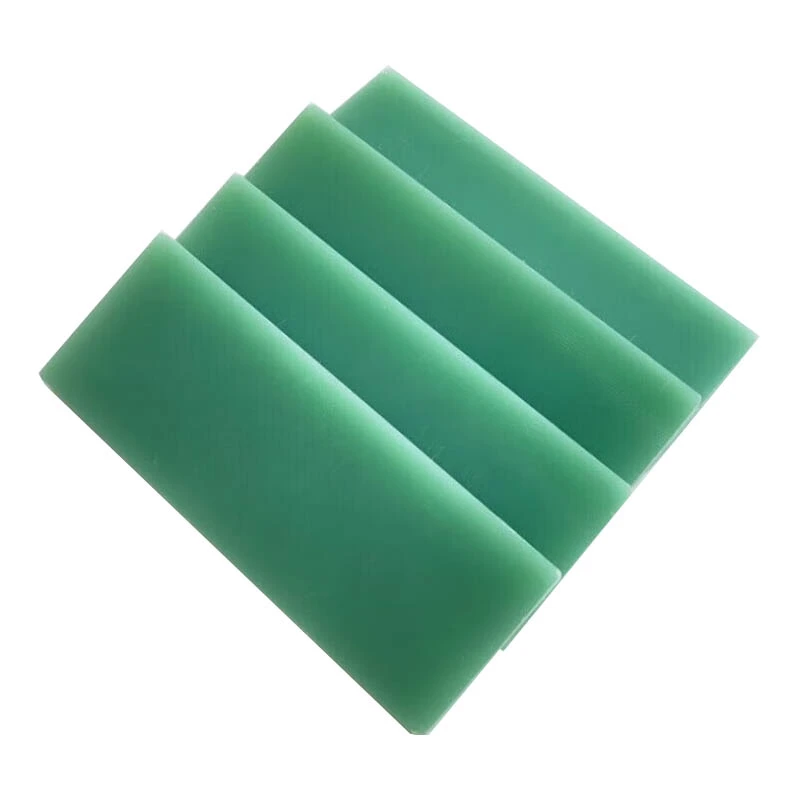

FR4, short for Flame Retardant 4, is a composite material consisting of woven fiberglass cloth impregnated with an epoxy resin binder. The manufacturing process of FR4 sheet involves layering multiple sheets of fiberglass fabric and infusing them with epoxy resin under heat and pressure. This results in a dense, uniform material with excellent electrical and mechanical properties. The FR4 epoxy sheet is typically produced in various thicknesses and sizes to accommodate different applications in the electronics industry.

Carbon Fiber Composition and Production

Carbon fiber is a polymer composed of long, thin strands of carbon atoms bonded together in a crystalline structure. The generation of carbon fiber includes a complex handle called pyrolysis, where forerunner materials such as polyacrylonitrile (Container) or pitch are warmed and extended to make high-strength carbon fibers. These fibers are at that point woven into textures or combined with tars to frame composite materials. The coming about carbon fiber items show uncommon strength-to-weight proportions and warm properties.

Comparative Analysis of Manufacturing Techniques

While both FR4 and carbon fiber involve composite manufacturing techniques, their production processes differ significantly. FR4 epoxy board production is relatively straightforward and cost-effective, making it suitable for large-scale manufacturing of electronic components. In contrast, carbon fiber production is more complex and energy-intensive, resulting in higher costs but yielding a material with superior mechanical properties. The choice between FR4 and carbon fiber often depends on the specific requirements of the application, balancing factors such as performance, cost, and scalability.

Physical and Mechanical Properties

Strength and Stiffness Comparison

FR4 sheet exhibits good mechanical strength and stiffness, making it suitable for use in electronic applications where dimensional stability is crucial. The glass fiber reinforcement provides excellent resistance to bending and warping, ensuring the integrity of circuit boards and electrical components. However, carbon fiber far surpasses FR4 in terms of strength and stiffness. Carbon fiber composites can achieve tensile strengths up to 10 times that of steel while weighing only a quarter as much. This exceptional strength-to-weight ratio makes carbon fiber ideal for applications where minimal weight and maximum structural integrity are required.

Thermal Properties and Heat Resistance

FR4 epoxy sheet demonstrates good thermal stability and heat resistance, with a glass transition temperature typically ranging from 130°C to 180°C. This allows FR4 to maintain its electrical and mechanical properties across a wide range of operating temperatures, making it suitable for various electronic applications. Carbon fiber, on the other hand, exhibits even higher thermal stability and can withstand temperatures exceeding 2000°C in some cases. This exceptional heat resistance makes carbon fiber valuable in high-temperature applications such as aerospace and automotive industries.

Density and Weight Considerations

One of the key differences between FR4 and carbon fiber lies in their density and weight. FR4 epoxy board has a density of approximately 1.8-1.9 g/cm³, which is relatively light compared to many metals but heavier than some plastics. This moderate density makes FR4 suitable for applications where weight is a consideration but not critical. Carbon fiber, with its density ranging from 1.5-2.0 g/cm³, offers a significant weight advantage, especially when considering its superior strength. The lightweight nature of carbon fiber makes it invaluable in aerospace, automotive, and sports equipment applications where weight reduction directly translates to improved performance and efficiency.

Applications and Industry-Specific Uses

Electronics and Electrical Applications

FR4 sheet dominates the electronics industry, serving as the primary material for printed circuit boards (PCBs) and electrical insulation components. Its excellent dielectric properties, dimensional stability, and flame-retardant characteristics make it ideal for a wide range of electronic devices, from consumer electronics to industrial control systems. FR4 epoxy sheet is also used in the manufacturing of transformers, switchgear, and other electrical equipment where reliable insulation is crucial. While carbon fiber has limited applications in electronics due to its conductivity, it finds use in EMI shielding and specialized electronic enclosures where strength and lightweight properties are required.

Aerospace and Automotive Industries

In the aerospace and automotive sectors, both FR4 and carbon fiber have distinct applications. FR4 epoxy board is used in aircraft and vehicle electronics, providing reliable insulation for critical systems. However, carbon fiber takes center stage in these industries due to its exceptional strength-to-weight ratio. Carbon fiber composites are extensively used in aircraft structures, spacecraft components, and high-performance automotive parts. The ability to reduce weight while maintaining or improving structural integrity has made carbon fiber an indispensable material in modern aerospace and automotive design, contributing to improved fuel efficiency and performance.

Sports and Recreation Equipment

While FR4 has limited applications in sports equipment, mainly in electronic components of fitness devices, carbon fiber has revolutionized the sports and recreation industry. Carbon fiber's lightweight and high-strength properties make it ideal for manufacturing high-performance bicycles, tennis rackets, golf clubs, and various other sporting goods. The material's ability to absorb vibrations and provide excellent stiffness has enhanced athlete performance across numerous sports. In contrast, FR4's role in this sector is primarily confined to the electronic components of sports-related devices and equipment.

Conclusion

FR4 and carbon fiber, while both composite materials, serve distinct purposes across various industries. FR4 sheet excels in electrical applications, offering reliable insulation, flame retardancy, and cost-effectiveness, making it the go-to material for PCBs and electronic components. Carbon fiber, with its unparalleled strength-to-weight ratio and thermal properties, dominates high-performance applications in aerospace, automotive, and sports industries. Understanding the unique properties and applications of these materials enables engineers and designers to make informed choices, leveraging the strengths of each material to drive innovation and efficiency in their respective fields.

Contact Us

For more information about our FR4 sheet, FR4 epoxy sheet, and FR4 epoxy board products, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect insulating sheet solution for your specific needs.