Fundamental Properties of FR4 Material

Chemical Composition and Manufacturing Process

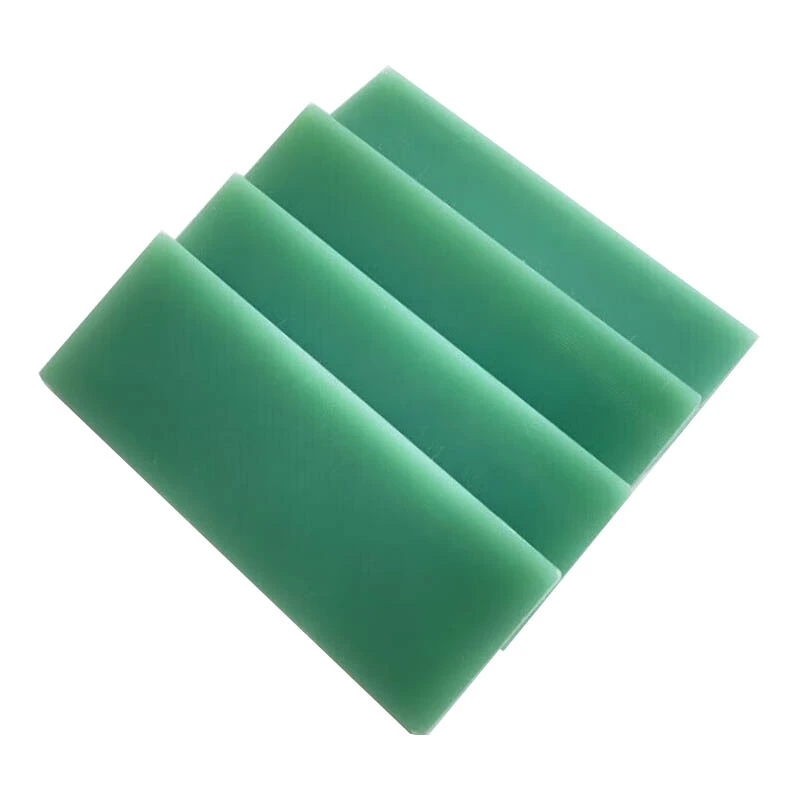

FR4 material, a composite of epoxy resin and woven glass fiber, is engineered for superior performance in electrical applications. Commonly produced in the form of FR4 sheets, the manufacturing process involves impregnating multiple layers of glass cloth with epoxy resin, followed by careful curing under controlled temperature and pressure conditions. This meticulous process results in a material with exceptional mechanical and electrical properties, making FR4 sheets crucial for diverse applications in the electrical industry.

Electrical Insulation Characteristics

One of the most salient features of FR4 is its outstanding electrical insulation properties. The material boasts a high dielectric strength, typically ranging from 20 to 80 kV/mm, depending on the specific grade and thickness. This characteristic makes FR4 sheet an excellent choice for applications requiring robust electrical isolation. Additionally, its low dielectric constant and dissipation factor contribute to minimal signal loss in high-frequency applications, making it ideal for use in printed circuit boards and other electronic components.

Thermal and Mechanical Properties

FR4 material exhibits remarkable thermal stability, maintaining its structural integrity and electrical properties across a wide temperature range. Typically manufactured as FR4 sheets, it has a glass transition temperature (Tg) between 130°C and 180°C, allowing it to withstand the heat generated in many electrical applications without deformation or loss of performance. Mechanically, FR4 sheets offer a high strength-to-weight ratio, excellent dimensional stability, and good machining characteristics, making them suitable for both structural and functional components in electrical devices.

FR4 Applications in Printed Circuit Boards

Multi-layer PCB Construction

FR4 sheet serves as the primary substrate material in multi-layer printed circuit boards, a cornerstone of modern electronics. Its excellent lamination properties allow for the creation of complex, multi-layer designs that can accommodate high-density component placement and intricate circuit patterns. The material's consistency and uniformity ensure reliable through-hole plating and via formation, critical for interconnecting different layers of the PCB. This capability enables the production of sophisticated electronic devices with reduced size and enhanced functionality.

High-Frequency Circuit Applications

In high-frequency applications, such as radio frequency (RF) and microwave circuits, FR4 sheets prove invaluable. Their low dielectric loss characteristics minimize signal attenuation, preserving signal integrity in high-speed digital and analog circuits. While specialized materials like PTFE composites may be preferred for extremely high-frequency applications, FR4 sheets remain a cost-effective and reliable choice for many RF and microwave PCB designs operating in the lower GHz range.

Flexible and Rigid-Flex PCB Implementations

FR4's versatility extends to flexible and rigid-flex PCB designs. By combining FR4 with flexible materials like polyimide, manufacturers can create hybrid boards that offer both the rigidity needed for component mounting and the flexibility required for compact, movable assemblies. This application is particularly valuable in devices with space constraints or those requiring dynamic PCB configurations, such as smartphones, wearable devices, and automotive electronics.

FR4 in Electrical Insulation and Structural Components

Transformer and Motor Insulation

FR4 material finds extensive use in transformer and motor insulation. Its high dielectric strength and thermal stability make it an excellent choice for insulating windings, core laminates, and other critical components in electrical machines. FR4 sheets can be precision-cut and shaped to form insulating barriers, spacers, and support structures within transformers and motors, enhancing their electrical performance and reliability. The material's resistance to oil and chemicals commonly used in these applications further contributes to its suitability in this domain.

Switchgear and Power Distribution Components

In switchgear and power distribution systems, FR4 sheets play a crucial role in insulation and structural support. Their excellent arc resistance and flame-retardant properties make them ideal for use in high-voltage environments. FR4 sheet components, such as bus bar supports, insulating barriers, and arc chutes, contribute to the safe and efficient operation of switchgear equipment. The material's mechanical strength and dimensional stability ensure that these critical components maintain their integrity under the stress of repeated switching operations and varying environmental conditions.

Custom Electrical Enclosures and Housings

FR4 sheet is increasingly utilized in the fabrication of custom electrical enclosures and housings. Its machinability allows for precise cutting, drilling, and shaping to create tailored solutions for specific electrical applications. These enclosures offer excellent electrical insulation, mechanical protection, and EMI/RFI shielding when properly designed. The material's light weight compared to metal alternatives, combined with its durability and fire-resistant properties, makes it an attractive option for portable electronic devices, industrial control panels, and specialized electrical equipment housings.

Conclusion

FR4 material has become an indispensable component in the electrical industry, offering a unique combination of electrical, thermal, and mechanical properties. Its versatility, especially in the form of FR4 sheets, in applications ranging from PCB manufacturing to electrical insulation and structural components underscores its significance in modern electrical engineering. As technology continues to evolve, FR4 sheets remain at the forefront of material choices for electrical applications, adaptable to new design challenges and performance requirements. The ongoing development of FR4 variants with enhanced properties promises to further expand its applications, ensuring its continued relevance in the ever-advancing field of electrical technology.

Contact Us

For more information about our FR4 sheet products and how they can benefit your electrical applications, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect FR4 solution for your specific needs.